Visual fuel rod

A fuel rod and fuel cladding technology, applied in the field of nuclear reactors, can solve the problems of velocity vector image distortion, measurement velocity error, difficulty in obtaining velocity vector diagram, etc., and achieve the effect of meeting the requirements of mechanical strength and facilitating collimation and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0024] One of the tasks of nuclear reactor thermal analysis is to analyze the temperature distribution of fuel elements and the flow and heat transfer characteristics of coolant. Liquid metal cooling fast reactor fuel rods and coolant are all made of metal, and typical non-contact optical velocimetry (such as particle image velocimetry) cannot obtain flow field data inside the component, so the present invention provides a visual fuel rod In order to meet the requirements of the optical velocity measuring device on the refractive index matching and light transmission of the fuel rod and the working medium.

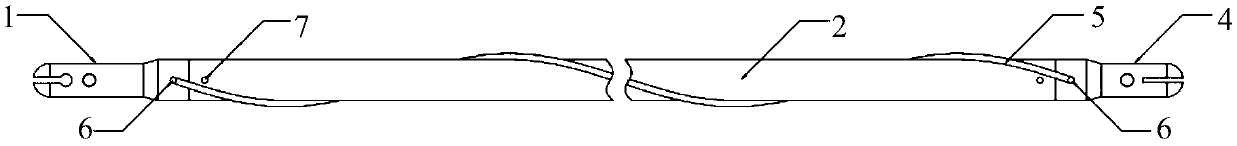

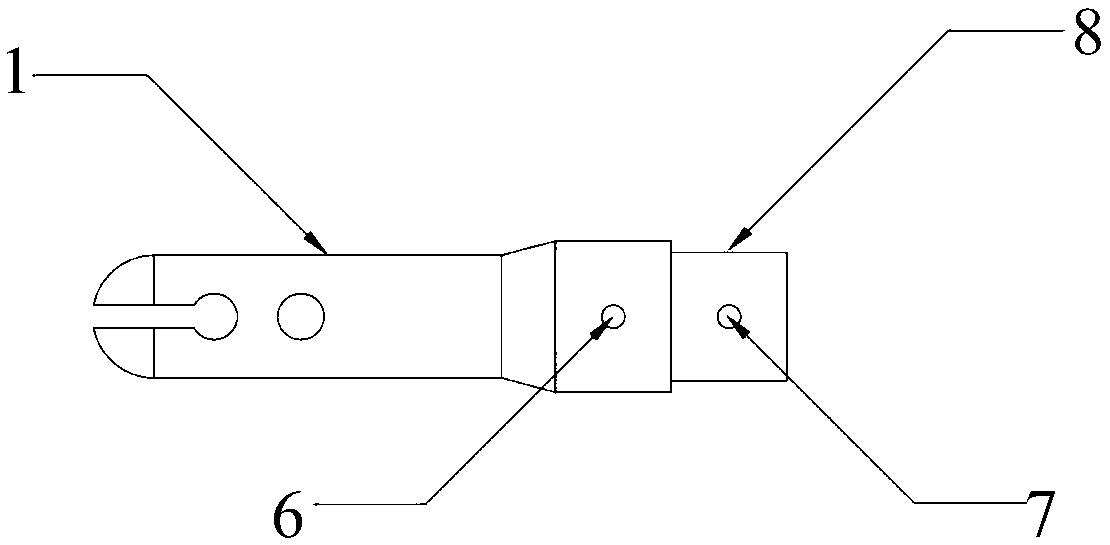

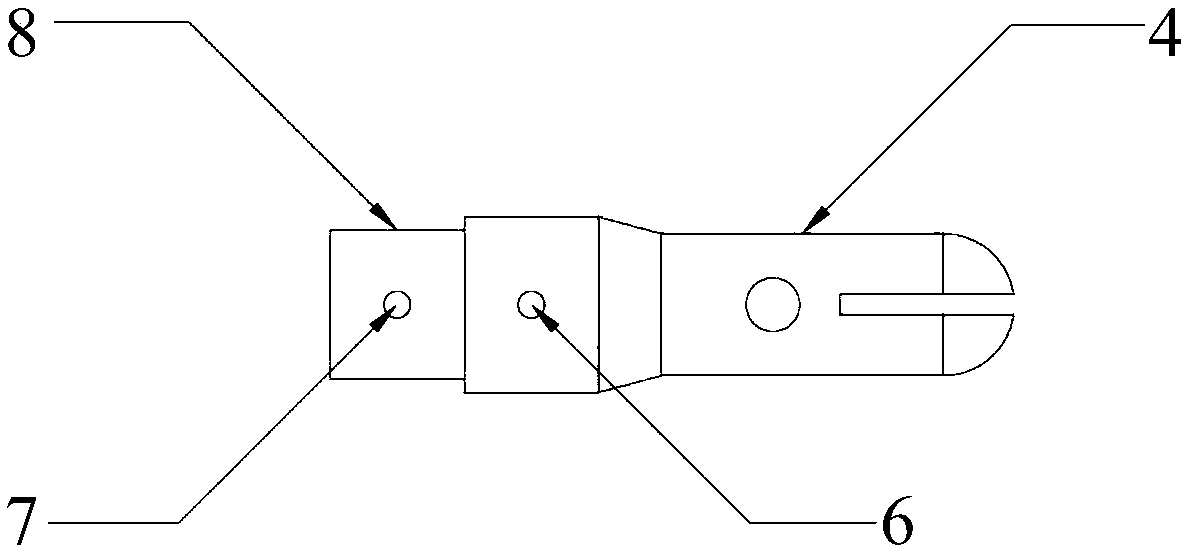

[0025] The present invention provides a visual fuel rod, comprising: a lower end plug 1, a fuel cladding 2, a liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com