Cell-biological material composite scaffold and its preparation method and application

A technology of composite scaffolds and biomaterials, applied in the direction of liquid material additive processing, processing and manufacturing, tissue regeneration, etc., can solve the problems of three-dimensional support environment that cannot provide cell growth, low adhesion rate, large pore size of scaffolds, etc., to achieve Improve the efficiency of 3D printing and be suitable for industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0126] A method for preparing a cell-biological material composite scaffold, comprising the following steps:

[0127] 1. Prepare scaffold matrix precursor slurry:

[0128] Inorganic nanoclay-based hydrogel is used as the precursor slurry of the scaffold matrix of the cell-biomaterial composite three-dimensional scaffold, and the preparation of the scaffold matrix precursor slurry is as follows:

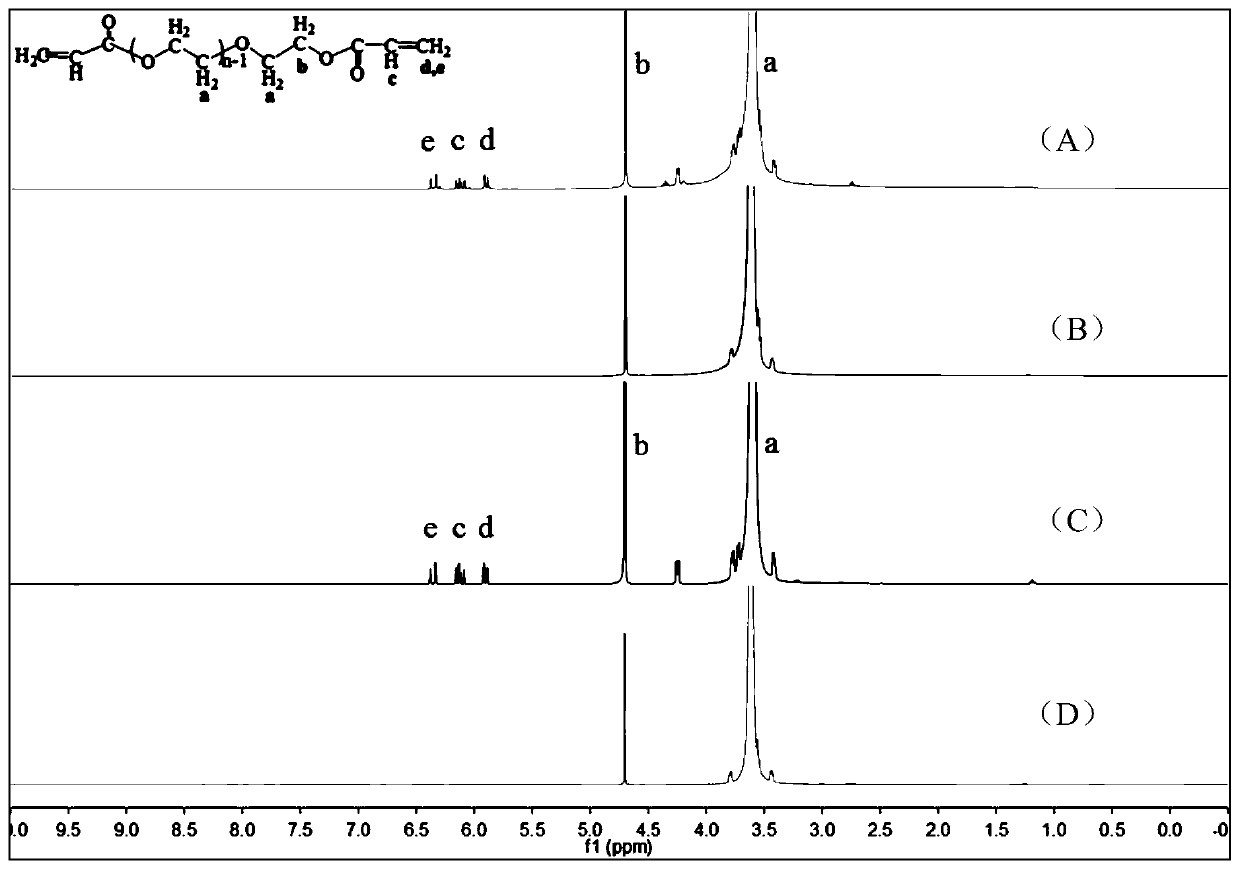

[0129] Get the polyethylene glycol macromolecular cross-linking agent modified by the above double bond, Laponite XLG laponite clay, UV photoinitiator 2-hydroxyl-2-methyl-1-phenyl-1-propanone and water to mix at room temperature , to obtain the scaffold matrix precursor slurry, the viscosity of which is 160Pa·s, wherein the above-mentioned raw materials are mixed according to the following mass percentages:

[0130] Polyethylene glycol diacrylate (molecular weight Mn=4000 of polyethylene) 20%

[0131] Laponite XLG clay: 5%

[0132] UV photoinitiator: 0.05%

[0133] Water: 74.95%.

...

Embodiment 2

[0146] A method for preparing a cell-biological material composite scaffold, comprising the following steps:

[0147] 1. Prepare scaffold matrix precursor slurry:

[0148] Inorganic nanoclay-based hydrogel is used as the precursor slurry of the scaffold matrix of the cell-biomaterial composite three-dimensional scaffold. The viscosity of the precursor slurry is 150 Pa s, including the following raw material components in mass percentage:

[0149] Crosslinking agent (methacrylic acid modified gelatin): 20%;

[0150] Laponite XLG clay: 7%;

[0151] UV photoinitiator: 0.05%;

[0152] Water: 72.95%;

[0153] Wherein, the ultraviolet photoinitiator is 1-[4-(2-hydroxyethoxy)-phenylene]-2-hydroxy-2', 2'-dimethylethanone (Irgacure2959).

[0154] 2. Prepare viscous cell suspension:

[0155] Dissolve hyaluronic acid in water to obtain a hyaluronic acid solution, resuspend human osteoblasts in the hyaluronic acid solution, and obtain a viscous cell suspension with a viscosity of 80P...

Embodiment 3

[0163] A method for preparing a cell-biological material composite scaffold, comprising the following steps:

[0164] 1. Prepare scaffold matrix precursor slurry:

[0165] Sodium alginate-based hydrogel is used as the precursor slurry of the scaffold matrix of the cell-biomaterial composite three-dimensional scaffold. The viscosity of the precursor slurry is 130 Pa s, including the following raw material components in mass percentage:

[0166] Crosslinking agent (polyvinyl alcohol modified with methacrylic acid): 20%;

[0167] Sodium alginate: 10%;

[0168] Water: 70%.

[0169] 2. Prepare viscous cell suspension:

[0170] Dissolve hyaluronic acid in water to obtain a hyaluronic acid solution, resuspend human bone marrow stem cells in the hyaluronic acid solution to obtain a viscous cell suspension with a viscosity of 200 Pa·s, in the viscous cell suspension, the mass fraction of hyaluronic acid 30%, the cell density is 2 x 10 6 individual / mL.

[0171] 3. Print composite ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com