Preparation method of anisotropic conductive adhesive film

An anisotropic conductive adhesive and conductive liquid technology, which is applied in the direction of conductive adhesives, film/sheet adhesives, adhesives, etc., can solve the problem that it is difficult to maintain the conduction resistance of electrodes, the distribution of conductive particles cannot be controlled, Material conductivity limitations and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

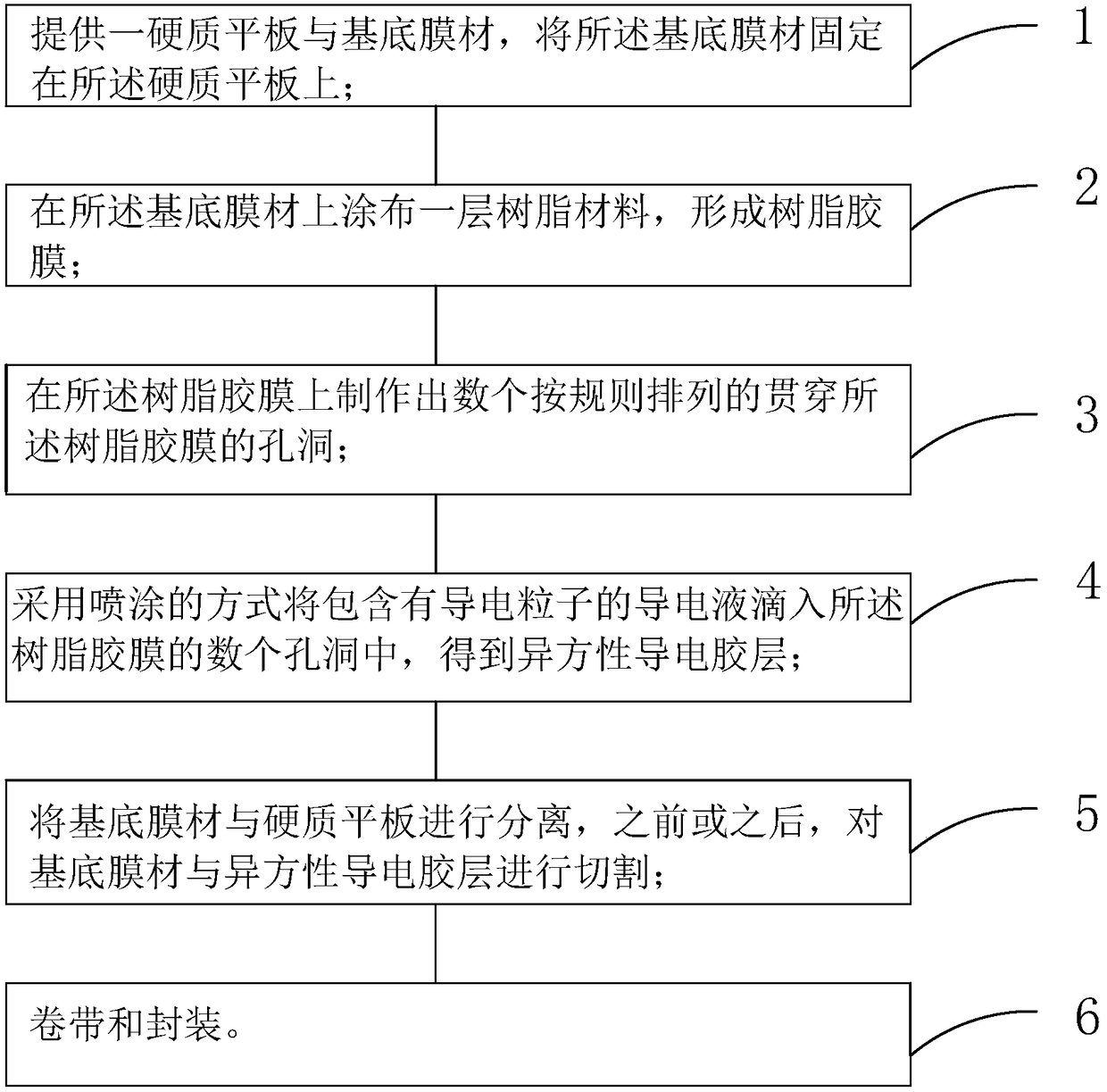

[0034] see figure 1 , the invention provides a kind of preparation method of anisotropic conductive adhesive film, comprising the following steps:

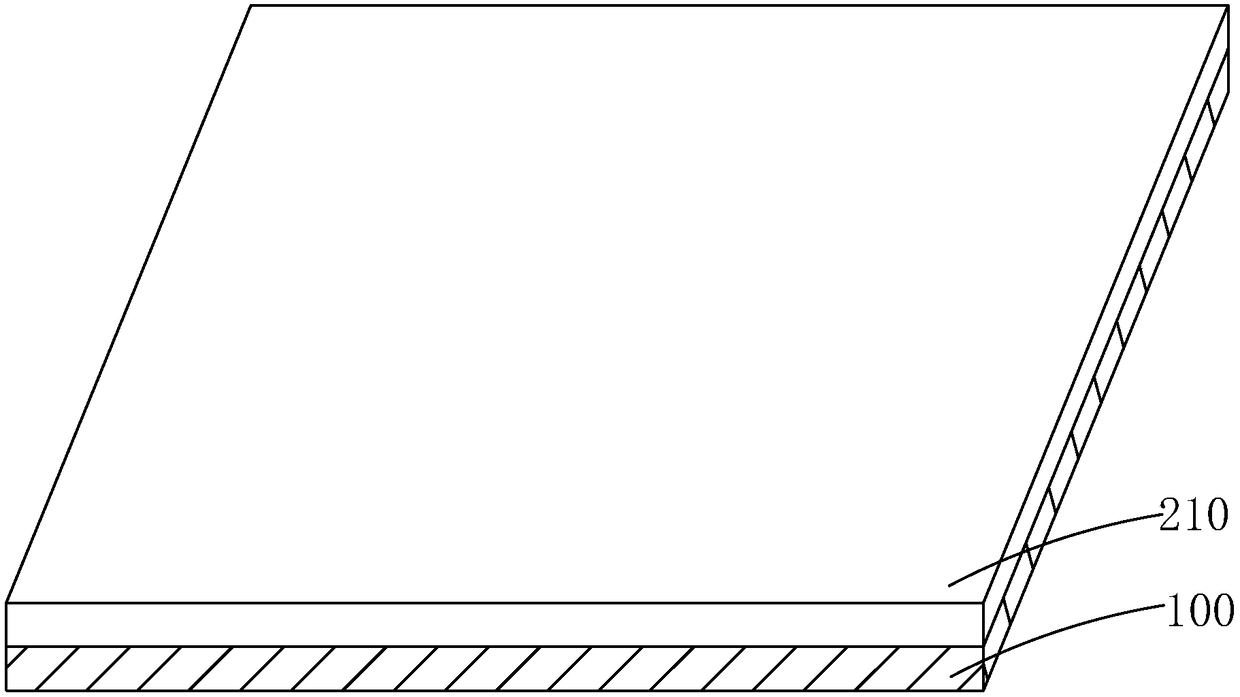

[0035] Step 1, such as Figure 2-3 As shown, a hard plate 100 and a base film material 210 are provided, and the base film material 210 is fixed on the hard plate 100 .

[0036] Wherein, the fixation of the base film material 210 on the hard plate 100 can be carried out by using the existing flexible film fixation method in the field, because it is a prior art, so it will not be repeated here.

[0037] Specifically, the hard plate 100 provided in step 1 is a glass plate.

[0038] Specifically, the base film material 210 provided in step 1 is a polyimide film.

[0039] Step 2, such as Figure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com