Response feedback type mechanochromic polymer material and preparation method thereof

A polymer material and chromic technology, applied in the field of response feedback type mechanochromic polymer materials and their preparation, can solve the problem of inability to feedback destructive stress, achieve novel technical route, strong product practicability, and overcome erroneous feedback Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The invention provides a response feedback type mechanochromic polymer material, the preparation method of which comprises the following steps:

[0039] S1. Copolymerize the target compound monomer, polyol monomer and polyisocyanate in which the color-changing group is connected in parallel with the self-reinforcing group to obtain a mechanochromic polymer;

[0040] Wherein, the molar content of the target compound monomer is 5% to 30%; the polyol monomer is polyethylene glycol, ethylene glycol, 1,3-propanediol, glycerol, 1,4-butanediol, 1, One or more of 5-pentanediol and 1,6-hexanediol; the polyisocyanate is hexamethylene diisocyanate (HDI), dicyclohexylmethane diisocyanate, diphenylmethane diisocyanate (MDI) , one or more of isophorone diisocyanate and toluene diisocyanate;

[0041] The chemical structural formula of the target compound monomer in which the color-changing group is connected in parallel with the self-enhancing group is:

[0042]

[0043]In the fo...

Embodiment 1

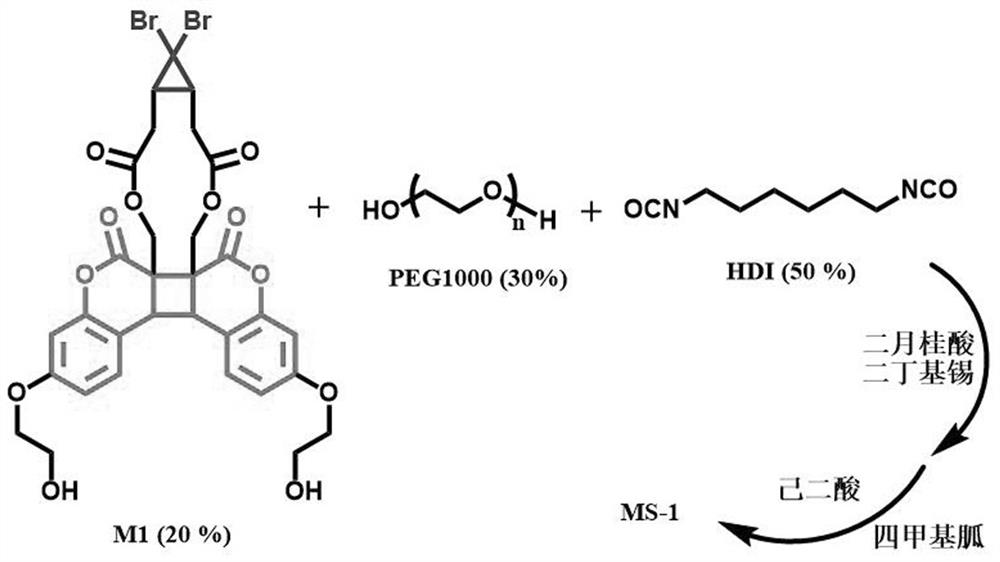

[0049] Example 1: Response Feedback Mechanochromic Polymer Material SM-1

[0050] refer to figure 2 , the preparation method of response feedback type mechanochromic polymer material SM-1, comprises the following steps:

[0051] Step a: preparing a target compound monomer in which a color-changing group and a self-enhancing group are connected in parallel, specifically including the following steps:

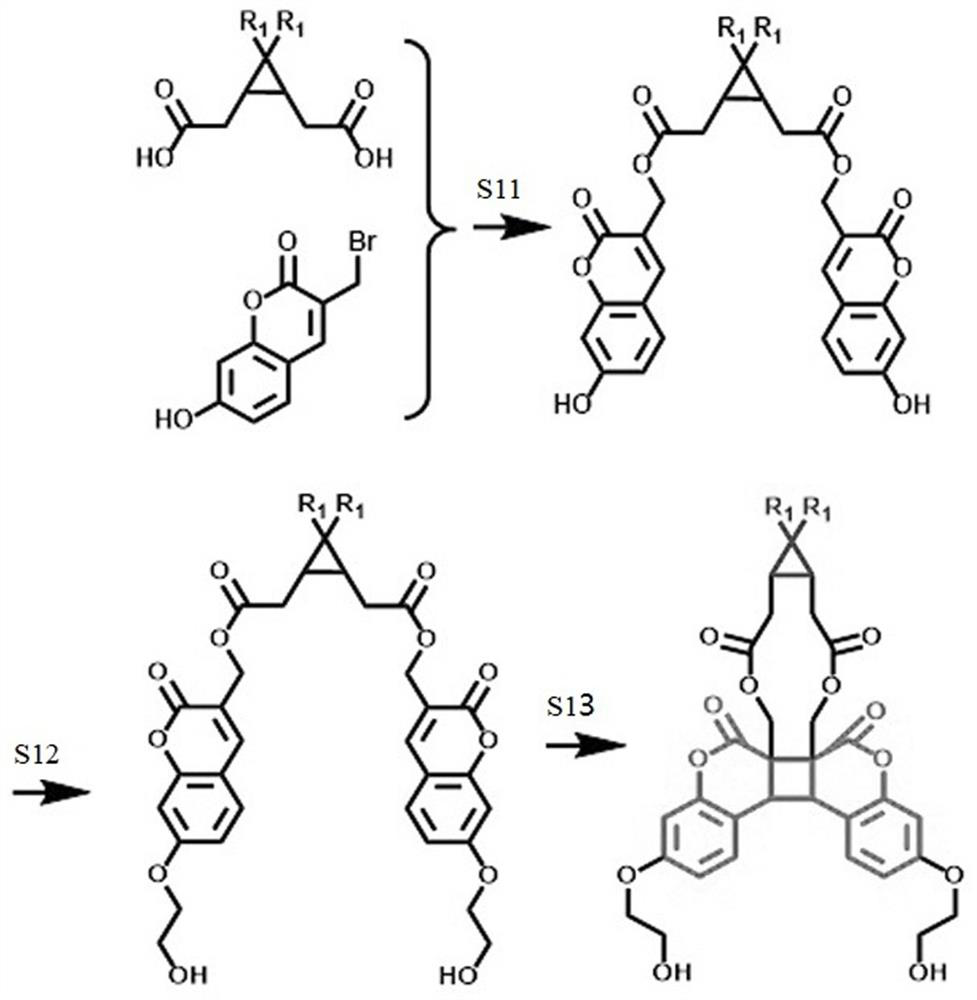

[0052] Step a1: Add dicarboxylic acid dibromocyclopropane (1eq.), bromocoumarin derivative (1eq.) and tetramethylguanidine (1eq.) to the solvent dimethyl sulfoxide, and react at room temperature After 3 hours, the system was poured into water, filtered and then vacuum-dried to obtain a coumarin derivative dimer;

[0053] Step a2: Mix the coumarin derivative dimer (1eq.), 2-bromoethanol (3eq.) and potassium carbonate (4eq.) obtained in step a1, add acetone to reflux reaction overnight, and concentrate the crude product Obtain the target compound precursor through column chroma...

Embodiment 2

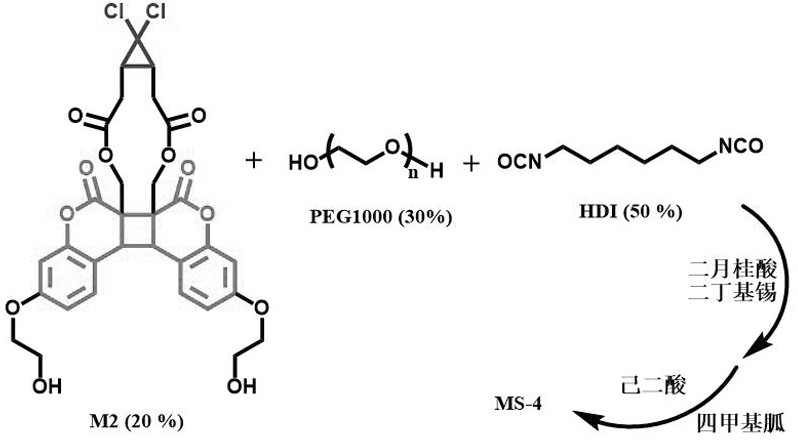

[0057] Example 2: Response Feedback Mechanochromic Polymer Material SM-2

[0058] The difference between the preparation method of the response feedback type mechanochromic polymer material SM-2 of this example and Example 1 is that the molar percentages of the target compound monomer M1, PEG1000 and HDI in step b are 5%, 45% and 50%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com