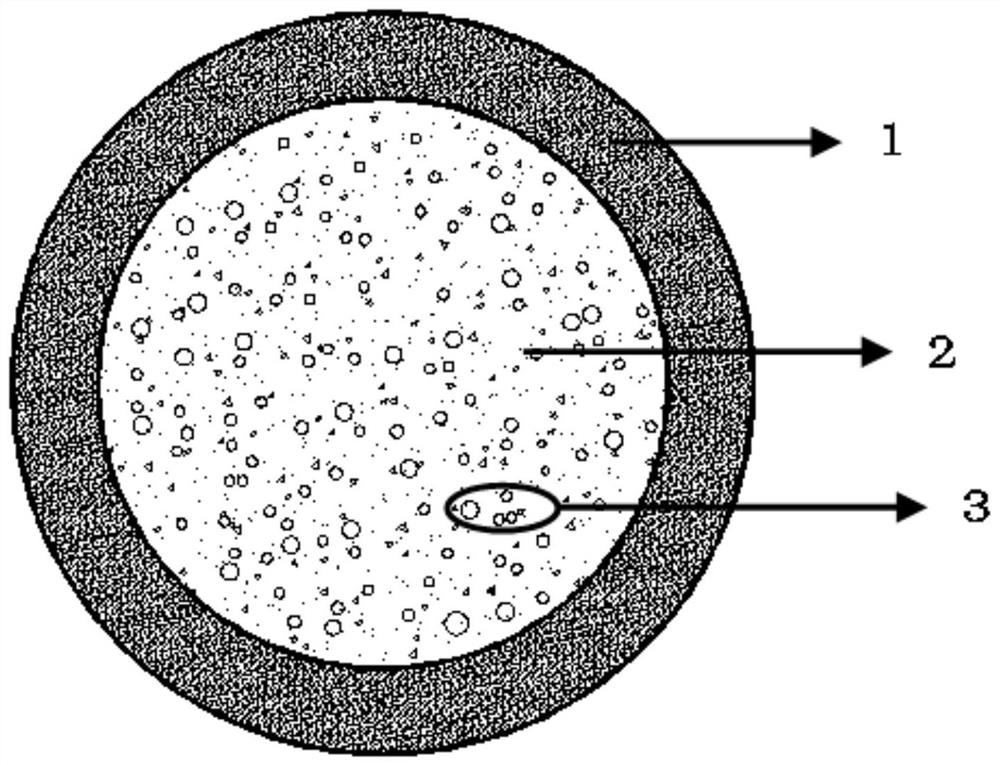

Phase-change heat-storage large capsule with metal core material coated with ceramic shell and preparation method of phase-change heat-storage large capsule

A metal core material and phase change heat storage technology, applied in the field of phase change energy storage, can solve the problems of inability to be recycled, large volume change rate, shell membrane bursting, etc., and achieve easy large-scale and continuous production, storage The effect of high heat density and low vapor pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

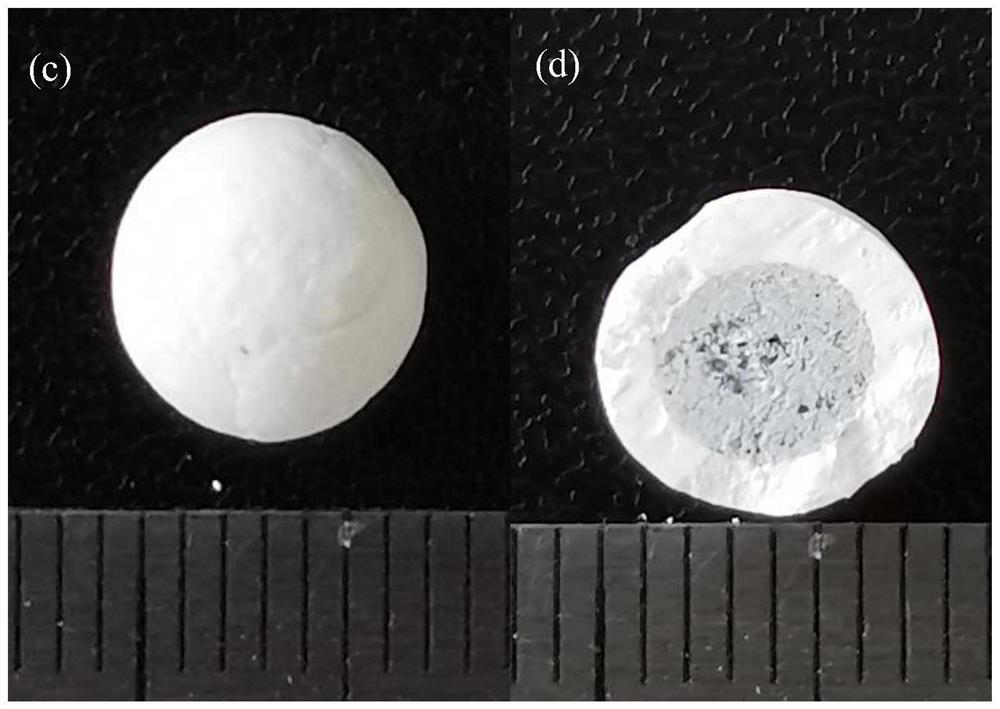

[0029] Example 1: Preparation of alumina ceramic shell-coated spherical Al-Si metal core macrocapsules

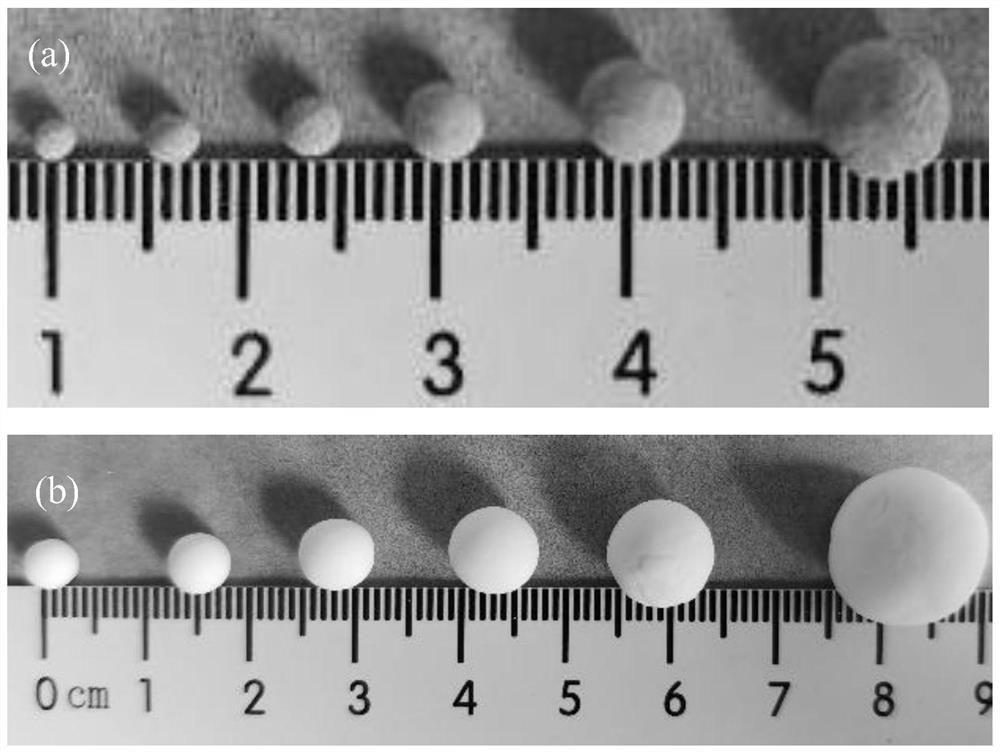

[0030] (1) With the Al-Si alloy metal powder with a particle size of 50 μm as the metal core raw material, the CMC binder is dissolved in deionized water (the quality of the CMC binder is 0.16g, and the quality of deionized water is 4g). Add 10g of Al-Si alloy metal powder into the above-mentioned binder solution, stir and mix, and after mixing evenly, manually form into balls to form spherical metal Al-Si green bodies with diameters of 1mm, 2mm, 3mm, 4mm, 6mm, and 8mm, and then Dry at 40 degrees Celsius for 72 hours to make a spherical Al-Si metal core material, as shown in figure 2 (a) shown.

[0031] (2) Al with a particle size of 20nm 2 o 3 For the ceramic powder raw material, the CMC binder is also dissolved in deionized water (the quality of the CMC binder is 0.16g, and the quality of deionized water is 4g), and then 1.5g Al 2 o 3 Add ceramic powder to the above...

Embodiment 2

[0034] Example 2: Preparation of spherical Al metal core macrocapsules coated with magnesium oxide ceramic shell

[0035] (1) Using Al metal powder with a particle size of 500 μm as the metal core material, dissolve the CMC binder in deionized water (the quality of the CMC binder is 0.16g, and the quality of deionized water is 4g), and take 10g of Al metal powder, add it to the above binder solution, stir and mix, and after mixing evenly, make spherical metal Al blanks with diameters of 10mm, 15mm, 20mm, 25mm, and 30mm respectively through spherical molds, and then dry them at 150 degrees Celsius for 1 hour to make them into spherical shapes. Al metal core material.

[0036] (2) Using MgO with a particle size of 5 μm as the ceramic powder raw material, the CMC binder is also dissolved in deionized water (the quality of the CMC binder is 0.16g, and the quality of deionized water is 4g), and then 1.5g of MgO ceramics is taken Add the powder into the above binder solution and st...

Embodiment 3

[0038] Example 3: Preparation of large spherical Al-Si-Cu metal core capsules coated with silicon nitride ceramic shells

[0039] (1) With the Al-Si-Cu metal powder with a particle size of 1 μm as the metal core material, the polyvinyl alcohol binder was dissolved in deionized water (the mass fraction of polyvinyl alcohol was 10%), and the Al-Si -Cu metal powder is added to the above binder solution and stirred and mixed (the mass ratio of metal powder to binder is 80:20), and after mixing evenly, spherical metal Al with diameters of 8mm, 12mm and 16mm are made respectively by a ball forming machine - Si-Cu body, and then dried at 70 degrees Celsius for 24 hours to make a spherical Al-Si-Cu metal core material.

[0040] (2) Be that the silicon nitride micropowder of 13 μm is the ceramic powder raw material with the particle diameter, the same polyvinyl alcohol binder is dissolved in deionized water (the mass fraction of polyvinyl alcohol is 20%), and the silicon nitride microp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com