Bypass air release quench chamber device

A technology for bypassing air and quenching chamber, which is used in lighting and heating equipment, gas treatment, direct contact heat exchangers, etc. and other problems, to achieve the effect of rapid enrichment, flexible layout and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

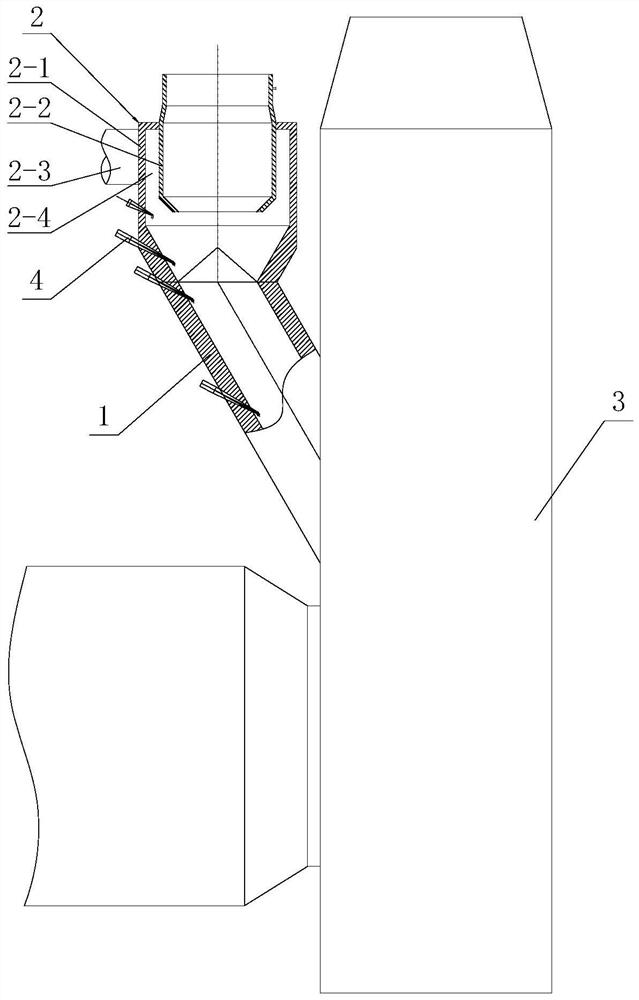

[0039] The quenching chamber device described in this example is used in a cement production line. Due to waste disposal and chlorine element exceeding the standard, a bypass scheme needs to be set up. According to the material balance, the air discharge volume is calculated to be 5%. Rotary kiln flue gas needs to be taken out. Ambient air enters the quench chamber through the blower as the cooling medium. Because the sulfur content in the flue gas is also high, it is necessary to spray lime at the outlet of the quenching chamber, so the temperature at the outlet of the quenching chamber is controlled at 400-450°C. After heat balance calculation, the required quench chamber diameter is 1.6m, and the design wind speed of each quench chamber is as follows:

[0040] Wind speed of hot air in the settling chamber: 6m / s; wind speed of cold air inlet in the quenching chamber: 20-25m / s; wind speed at the annular inlet of the quenching chamber: 10-15m / s; wind speed of hot air entering...

Embodiment 3

[0046] see Figure 4 , the present embodiment is the purifying system comprising this quenching chamber device, and the outlet of the quenching chamber of the quenching chamber device is connected in series successively with a cyclone dust collector 5, a dust collector 6, a blower fan 7, an exhaust gas treatment system 8 and a chimney 9, and the cyclone The dust outlet of the dust remover 5 communicates with the quench chamber 2 . The cyclone dust collector 5, the dust collector 6, the fan 7, the waste gas treatment system 8 and the chimney 9 are conventional structures in the field, and the cyclone dust collector 5 collects dust from the gas discharged from the quench chamber 2 and enters the calciner of the cement kiln system. At this time, the amount of ash returned decreases, and the total amount of hot air taken out of the smoke chamber increases. Combined with the layout of the cement production line, the bypass flue gas passes through the fan 7 and is introduced into t...

Embodiment 4

[0048] see Figure 5 , on the basis of Embodiment 1, after the outlet of the quench chamber 2, the humidification tower 10, the dust collector 6, the fan 7, the exhaust gas treatment system 8 and the chimney 9 are connected in series. The humidifying tower 10, the dust collector 6, the fan 7, the waste gas treatment system 8 and the chimney 9 are conventional structures in the field. The humidifying tower 10 cools the flue gas discharged from the quench chamber, and the air volume of the dust collector will decrease at this time. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com