Device and method for transporting materials quantitatively and mixing and packaging integrated equipment

A material and packaging technology, applied in the field of food and drug processing equipment, can solve problems affecting product quality stability, large differences in packaging contents, and low work efficiency, and achieve the effect of reducing content differentiation, easy implementation, and rapid processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

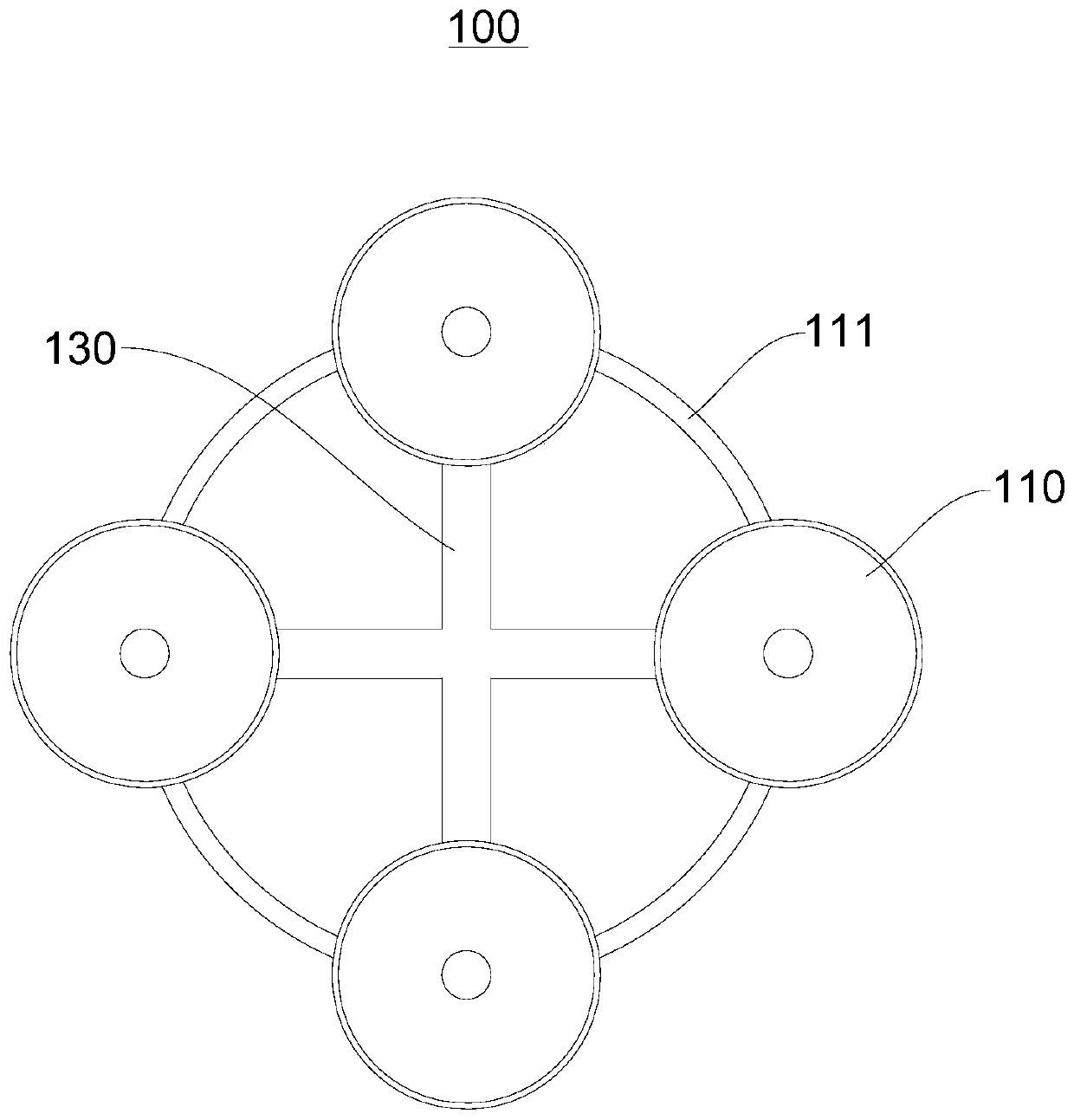

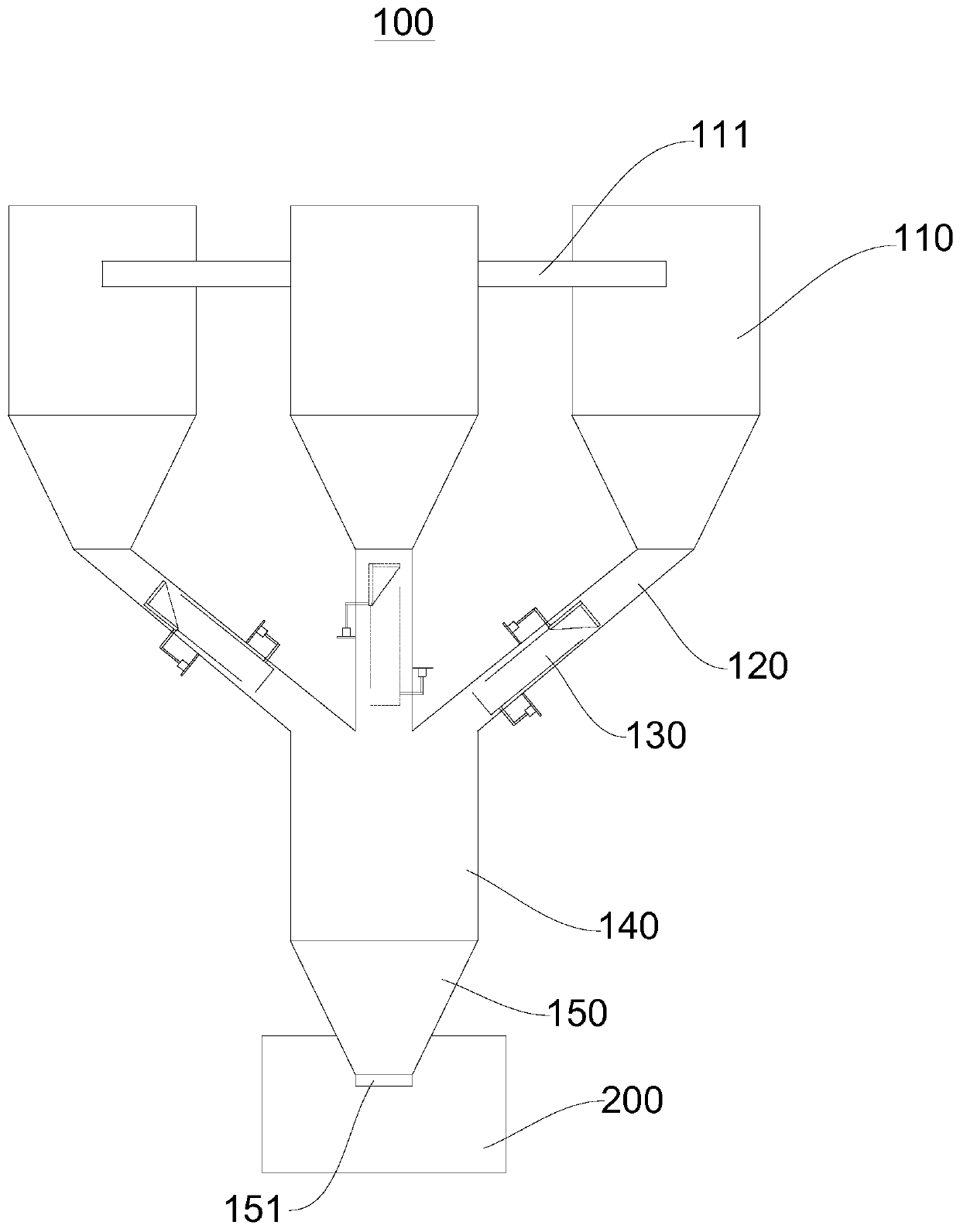

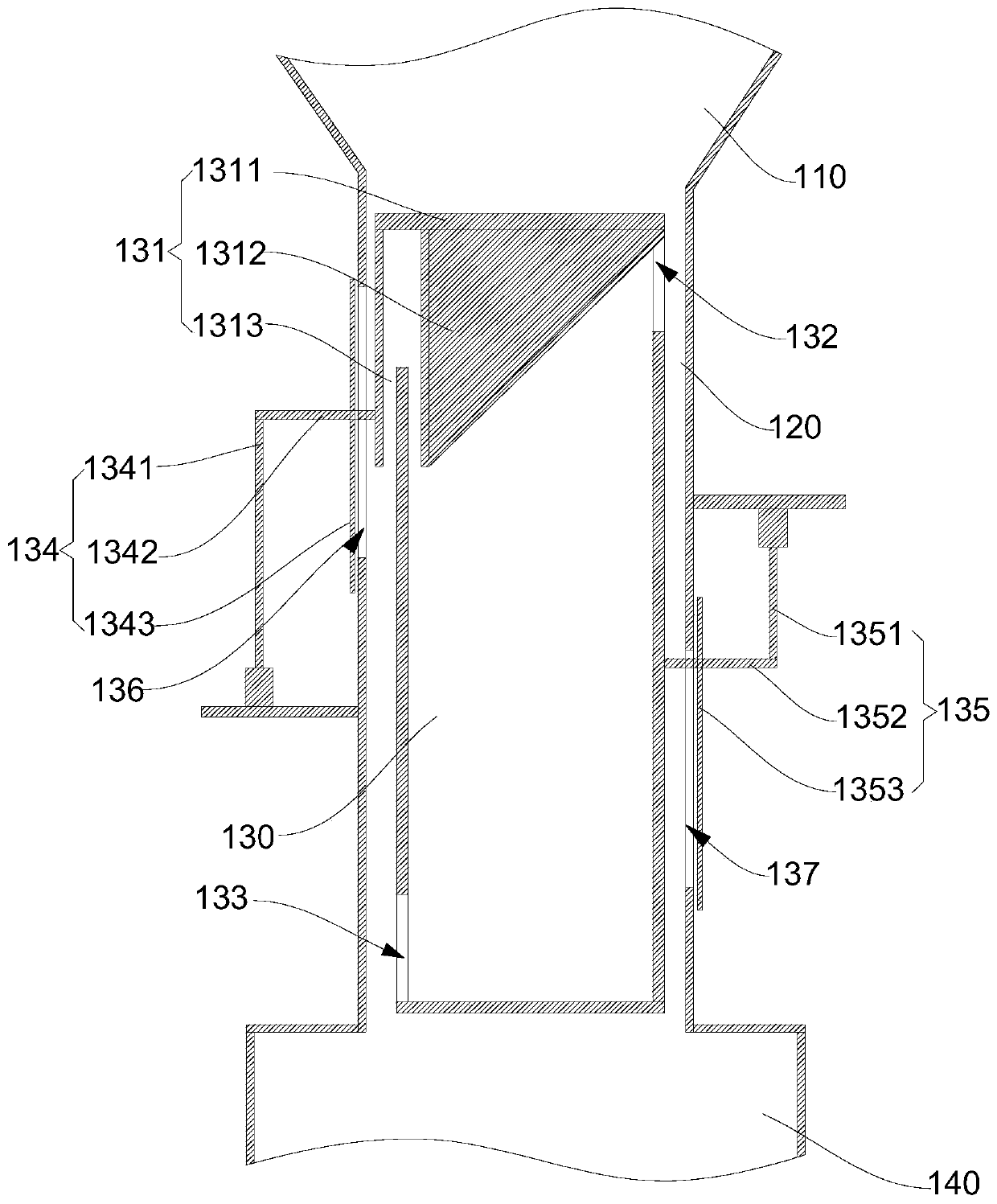

[0040] Please refer to figure 1 and figure 2 , this embodiment provides an integrated equipment for mixing and packaging, which includes a material quantitative transportation device 100 and a packaging mechanism 200 .

[0041] Wherein, the device 100 for quantitatively transporting materials includes a feeding barrel 110 , a feeding channel 120 , a quantitatively transporting pipeline 130 , a mixing bin 140 and a material output packaging port 150 . The top of the feeding channel 120 communicates with the bottom of the feeding barrel 110 , and the bottom of the feeding channel 120 communicates with the mixing bin 140 . The output packaging port 150 communicates with the bottom of the mixing bin 140 , and the packaging mechanism 200 communicates with the output packaging port 150 .

[0042] Wherein, the feeding barrel 110 is used for the operator to put in the materials to be packaged. The feeding barrel 110 in this application is funnel-shaped, specifically, its upper part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com