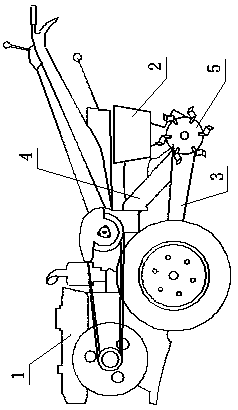

Uniform fertilizer spreading device

A fertilizer spreading device and uniform technology, applied in the directions of fertilizing devices, fertilizer distributors, shovels, etc., can solve the problems of poor uniformity of fertilizer spreading, and achieve the effect of avoiding fertilizer waste and having a compact and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

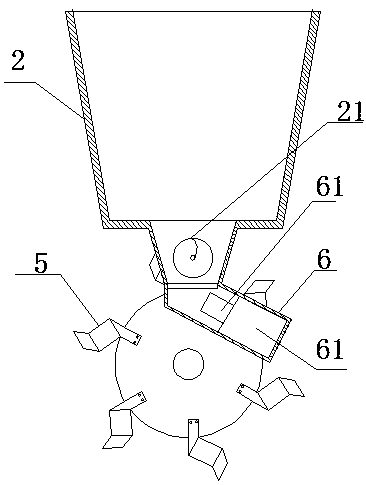

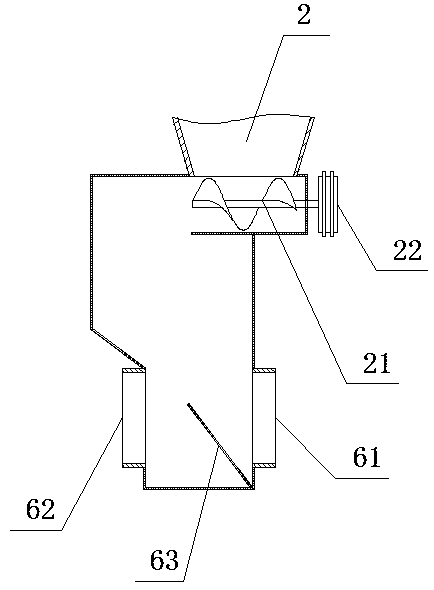

[0020] In this embodiment, for rational layout, the screw conveying device is fixed on one side of the fertilizer spreading bin, and its outlet is located on the upper side of the fertilizer spreading bin, and the opposite side of the fertilizer spreading bin and the screw conveying device is provided with an inward curved The bent plate is bent, and the fertilizer transported by the screw conveyor will slide down under the action of the bent plate and be squeezed to the fertilizer spreading ports on both sides through the action of the partition. In the present embodiment, the bending plate and the dividing plate have the same inclination angle, and the distance between the ends of the dividing plate and the fertilizer spreading ports on both sides is equal, and the dividing plate is just in the middle of the fertilizer spreading bin to separate the fertilizer evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com