Sludge treatment system for slurry circulation in drilling engineering

A sludge treatment and slurry technology, which is used in sludge treatment, water/sludge/sewage treatment, mining wastewater treatment, etc., to save labor, reduce equipment volume, and improve mixing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

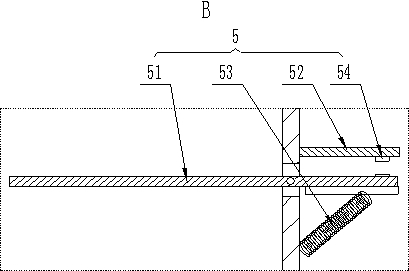

[0035] like image 3 As shown, in the present embodiment, the specific structure of the start-stop switch 5 of another structure is as follows: it includes a rotating plate 51 and a detection plate 52, the rotating plate 51 passes through the comprehensive mixing pipe 2, and the middle part of it can be rotated up and down and is hinged on the On the comprehensive mixing pipe 2, the rotating plate 51 is connected to the comprehensive mixing pipe 2 through a spring 53 outside the comprehensive mixing pipe 2. In the balanced state without external force, the rotating plate 51 is in a horizontal state, and the detection plate 52 is set on the comprehensive mixing pipe 2. On the outer wall, and at the top of the rotating plate 51, the bottom of the detection plate 52 is provided with a proximity sensor 54 that can detect the proximity of the rotating plate 51, and the proximity sensor 54 is connected to the spraying device 3 and the mixing mechanism 4 for signal, That is, when the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com