A sludge treatment system for drilling engineering mud circulation

A technology for sludge treatment and mud, which is applied in the direction of sludge treatment, water/sludge/sewage treatment, mining wastewater treatment, etc. It can solve the problems of unsatisfactory sludge treatment, multiple mixing dead ends, waste of consumables, etc. Achieve the effect of saving equipment consumables, improving mixing effect and improving mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

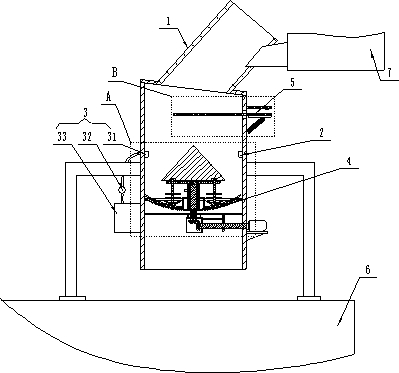

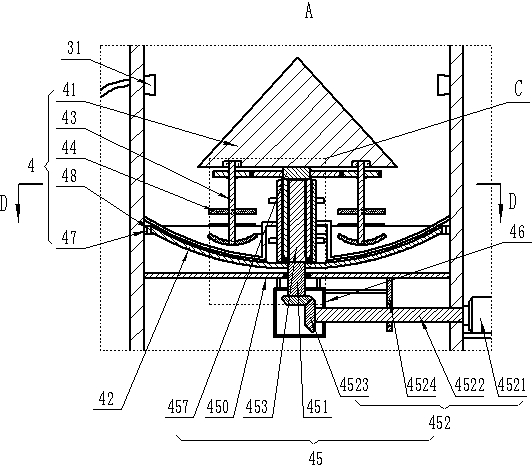

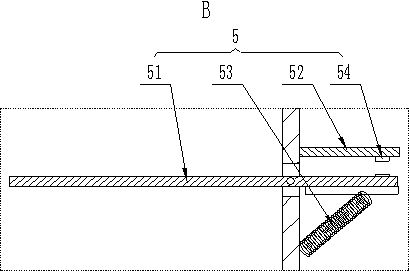

[0035] Attached to the following Figure 1-7 The invention is described in further detail.

[0036] The embodiment of the invention discloses a sludge treatment system for drilling engineering mud circulation. refer to figure 1 , a sludge treatment system for drilling engineering mud circulation, including vibrating screen 7 and sedimentation tank 6, vibrating screen 7 is the equipment of the mud circulation system, waste mud sludge is discharged from the vibrating screen 7, and the sludge of the vibrating screen 7 is discharged. Between the mud outlet and the sedimentation tank 6, a converging pipe 1 arranged obliquely and a fully integrated pipe 2 arranged vertically are arranged in sequence. Schematically), the sedimentation tank 6 is located directly below the outlet of the fully integrated mixed pipe 2, and the fully integrated mixed pipe 2 is provided with a spray device 3 that can spray chemicals on the sludge passing through the fully integrated mixed pipe 2 and a sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com