Fischer-Tropsch catalyst, as well as preparation method and application thereof

A Fischer-Tropsch synthesis and catalyst technology, which is applied in chemical instruments and methods, preparation of liquid hydrocarbon mixtures, physical/chemical process catalysts, etc., can solve problems such as uneven mixing, and achieve improved quality stability, stable quality, and high response active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

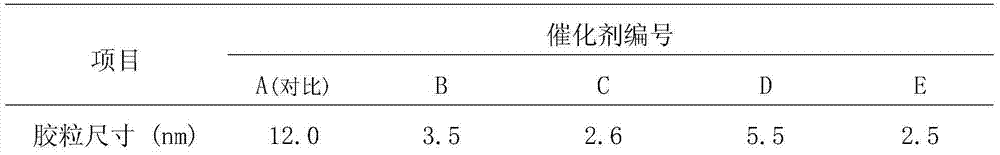

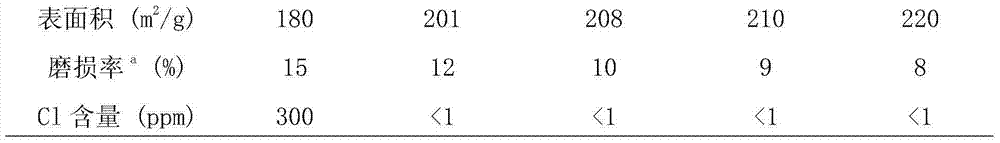

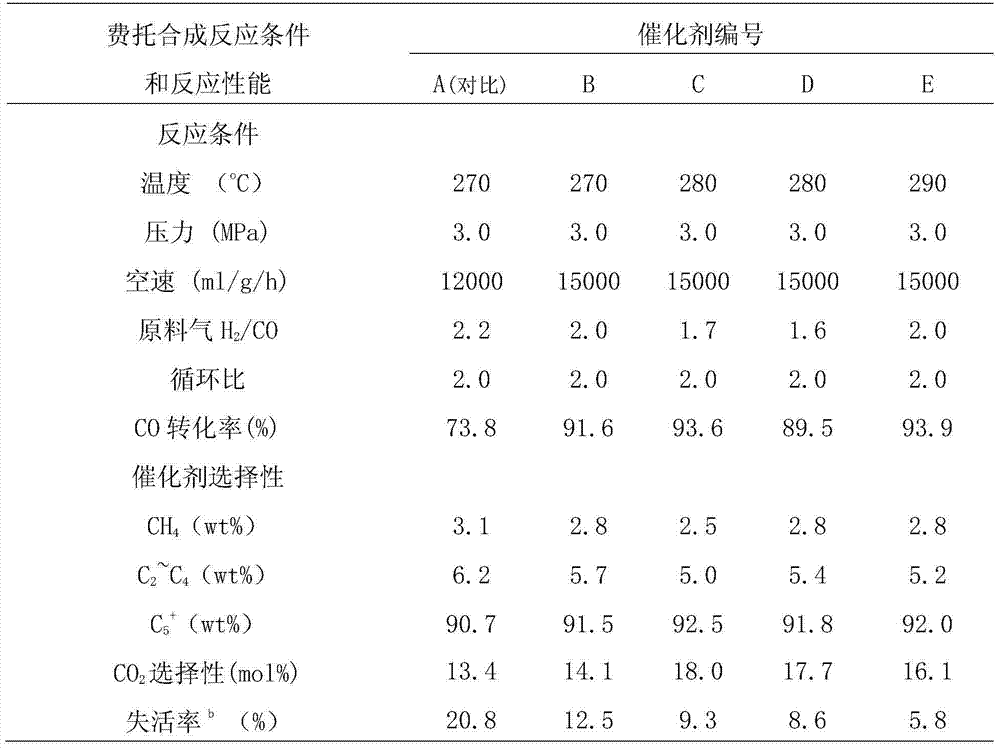

Embodiment 1

[0072] Take by weighing 19.8 kilograms of potassium silicate and prepare 10wt% potassium silicate solution, pass through the 001×7 strongly acidic styrene-based cation exchange resin with a pH value of 6-7 under the condition of 25mL / min at a flow rate to obtain a pH= 5-6 silicic acid solution, pass this silicic acid solution through 201×7 strongly basic styrene-based anion exchange resin with a pH value of 8-9 at a flow rate of 20mL / min to obtain SiO 2 Concentration is 112 kilograms of active silicic acid solution of 5%; In described active silicic acid solution, add 0.85 kilogram of iron nitrate nonahydrate (SiO 2 The mass ratio of Fe to Fe is 100:1.97), fully dissolved, aged at 80°C for 5 hours, and added after dissolving 211.75 kg of ferric nitrate nonahydrate to obtain an aged active silicic acid solution containing Fe; then added to the mixed nitrate solution (taking by weighing 5.7 kilograms of copper nitrate trihydrate, 35.8 kilograms of 50wt% manganese nitrate solutio...

Embodiment 2

[0076] Take by weighing 19.8 kilograms of potassium silicate and prepare 10wt% potassium silicate solution, pass through the 001×7 strongly acidic styrene-based cation exchange resin with a pH value of 6-7 under the condition of 25mL / min at a flow rate to obtain a pH= 5-6 silicic acid solution, pass this silicic acid solution through 201×7 strongly basic styrene-based anion exchange resin with a pH value of 8-9 at a flow rate of 20mL / min to obtain SiO 2 112 kg of active silicic acid solution with a concentration of 5%; 212.6 kg of ferric nitrate nonahydrate was dissolved and added to the active silicic acid solution to obtain a mixed solution 1, and the mixed solution 1 was aged at 30°C for 2 hours to obtain Aged reactive silicic acid solution of Fe (SiO 2 The mass ratio of Fe and Fe is 20:100); In the aging active silicic acid solution containing Fe, add the mixed nitrate solution prepared in advance (weigh 5.7 kilograms of copper nitrate trihydrate, 35.8 kilograms of 50wt% m...

Embodiment 3

[0078] Take by weighing 19.8 kilograms of potassium silicate and prepare 10wt% potassium silicate solution, pass through 001×7 strong acid styrene cation exchange resin with pH value of 6-7 under the condition of flow rate of 25mL / min, to obtain pH=5 -6 silicic acid solution, pass this silicic acid solution through 201×7 strongly basic styrene-based anion exchange resin with a pH value of 8-9 at a flow rate of 20mL / min to obtain SiO 2 Concentration is 112 kilograms of active silicic acid solution of 5%; In active silicic acid solution, add 8.5 kilograms of iron nitrate nonahydrate (SiO 2 The mass ratio of Fe and Fe is 100:20), fully dissolved, aged 3h at 50°C, and added after dissolving 204.09 kg of ferric nitrate nonahydrate to obtain an aging active silicic acid solution containing Fe; then added to the mixed nitrate solution ( Take by weighing 5.7 kilograms of copper nitrate trihydrate, 35.8 kilograms of 50wt% manganese nitrate solution and be dissolved in deionized water t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com