Surface overlaying method of foot roll of continuous casting machine

A surface surfacing and continuous casting machine technology, which is applied in the field of surfacing welding, can solve the problem of low pass rate of surfacing welding on the surface of continuous casting machine foot rolls, short service life of continuous casting machine foot rolls, thermal cracks in surfacing layers and welds, etc. problems, to achieve good toughness and wear resistance, reduce maintenance costs, and reduce thermal cracks in the surfacing layer and welds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1 A continuous casting machine foot roll with a diameter of 20cm / inner diameter of 10cm was selected, and the surfacing was carried out according to the following steps:

[0026] 1) Pretreatment of continuous casting machine foot roll

[0027] Preheat and keep warm at 180°C for 3 h before welding.

[0028] 2) Soil preparation

[0029] a. Choose clean clay. The particle size ratio of the clay is: 0.05mm 20%, 0.005mm 30%, 1um 50%. After clay with different particle sizes is mixed with water, the mud mass formed has less gaps, which is conducive to the heat absorption of the soil and timely delivery;

[0030] b. According to the weight ratio of clay: water = 5:1, ensure that the clay is fully wet, which is convenient for filling in the foot roll of the continuous casting machine, and will not cause the soil to leave the inner surface of the roll during the surfacing rotation process due to too thin soil. Take the corresponding amount of clay and wate...

Embodiment 2

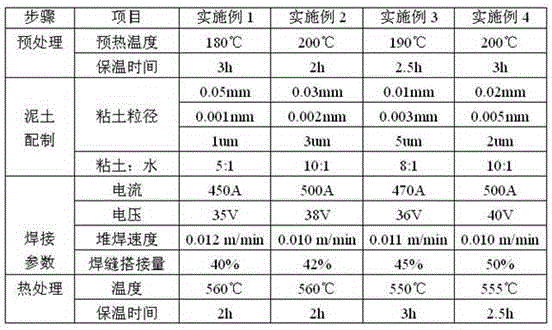

[0043] Example 2 The process was carried out in the same manner as in Example 1. The specific parameters are shown in Table 1. The performance test was performed on the foot roll of the continuous casting machine after surfacing, and the specific data were shown in Table 2 below.

Embodiment 3

[0044] Example 3 The process was carried out in the same manner as in Example 1. The specific parameters are shown in Table 1. The performance test of the foot roll of the continuous casting machine after surfacing was carried out. The specific data are shown in Table 2 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com