Forged steel piece welding method

A welding method and forged steel technology, which is applied in the field of forged steel welding, can solve problems such as cold cracks and hot cracks, achieve the effects of reducing cold cracks and hot cracks, ensuring welding quality, and preventing welding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

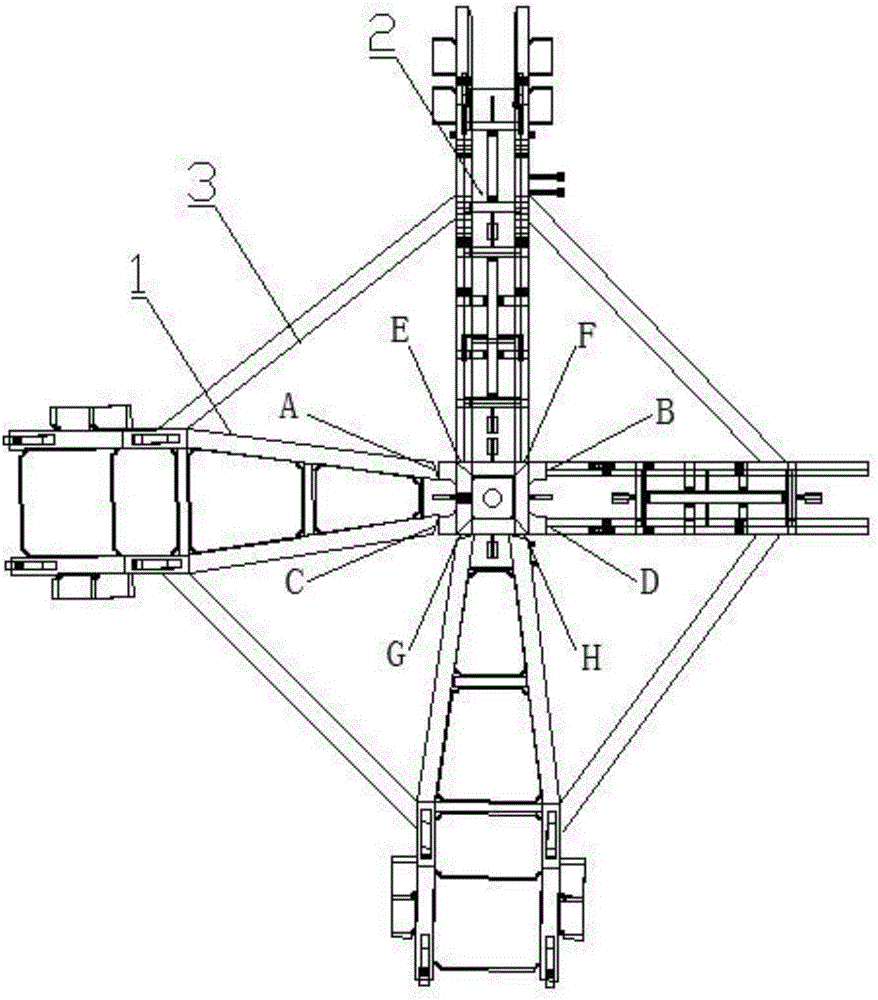

Image

Examples

Embodiment Construction

[0028] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments.

[0029] A method for welding forged steel parts, comprising the following steps:

[0030] Assembly and cleaning before welding: Assemble the steel forgings and clean the welds to be welded;

[0031] Preheating before welding: preheating the weld;

[0032] Welding: The welding seam is welded by layering and de-welding, and the temperature of the welding seam is controlled during the welding process;

[0033] Post-weld heat: The weld is heated and then insulated.

[0034] The welding method ensures the welding quality through rigorous pre-welding preparations, reasonable welding process sequence, and standardized temperature control measures, effectively reduces the generation of cold cracks and hot cracks, and prevents welding deformation.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com