A Dense Array High-Speed Micro-Stamping Equipment

A micro-stamping and equipment technology, applied in metal processing equipment, manufacturing tools, punching tools, etc., can solve the problems of complex micro-stamping dies, limited stamping accuracy of stamping machines, complex stamping dies, etc., to reduce complexity and production costs, Improve production efficiency and ensure the effect of stamping quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

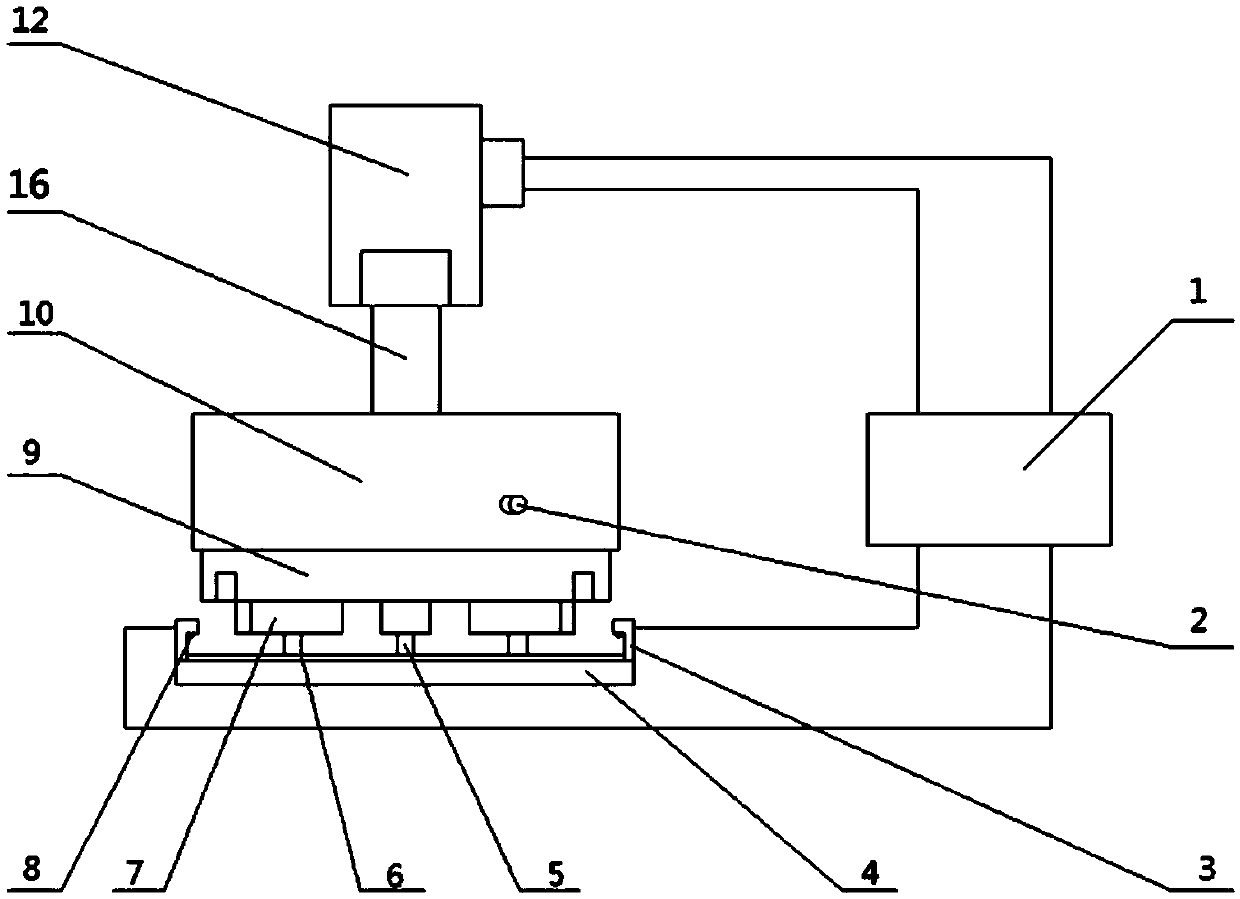

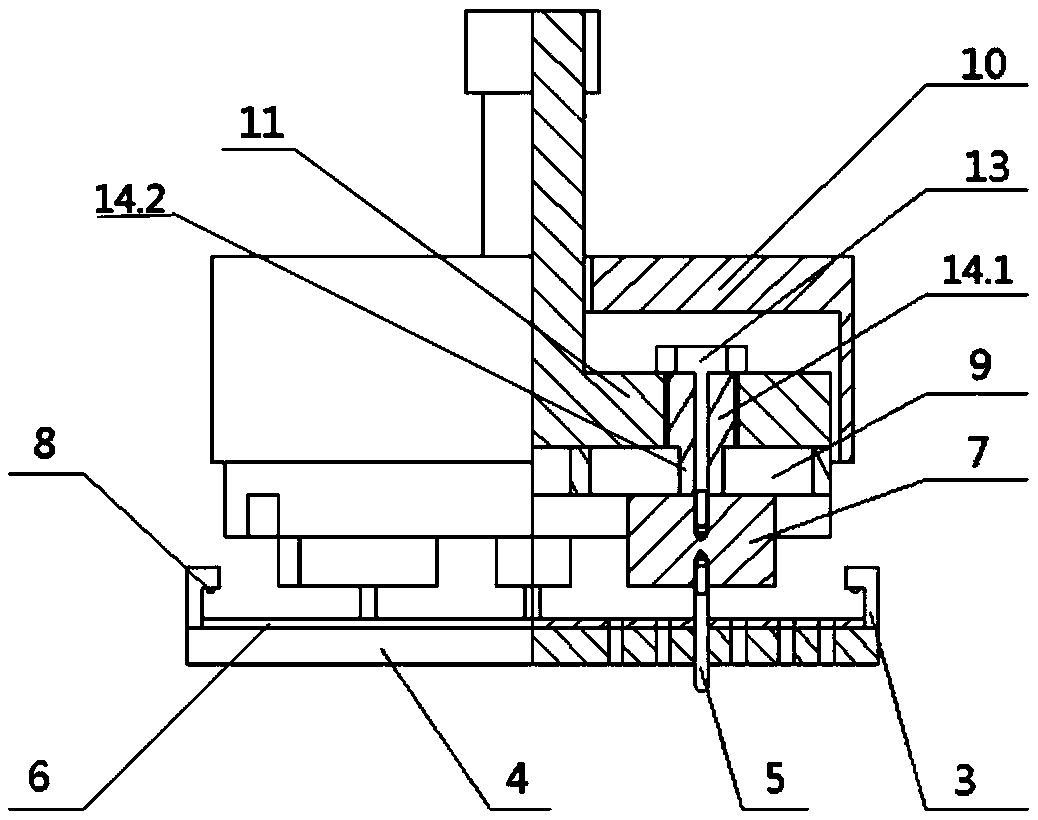

[0035] Such as Figure 1 to Figure 7 As shown, a dense array of high-speed micro-stamping equipment includes a punch clamping and positioning device, a stamping parameter adjustment device, a workpiece clamping and positioning device, and a lifting drive device that drives the punch clamping and positioning device to perform lifting movements.

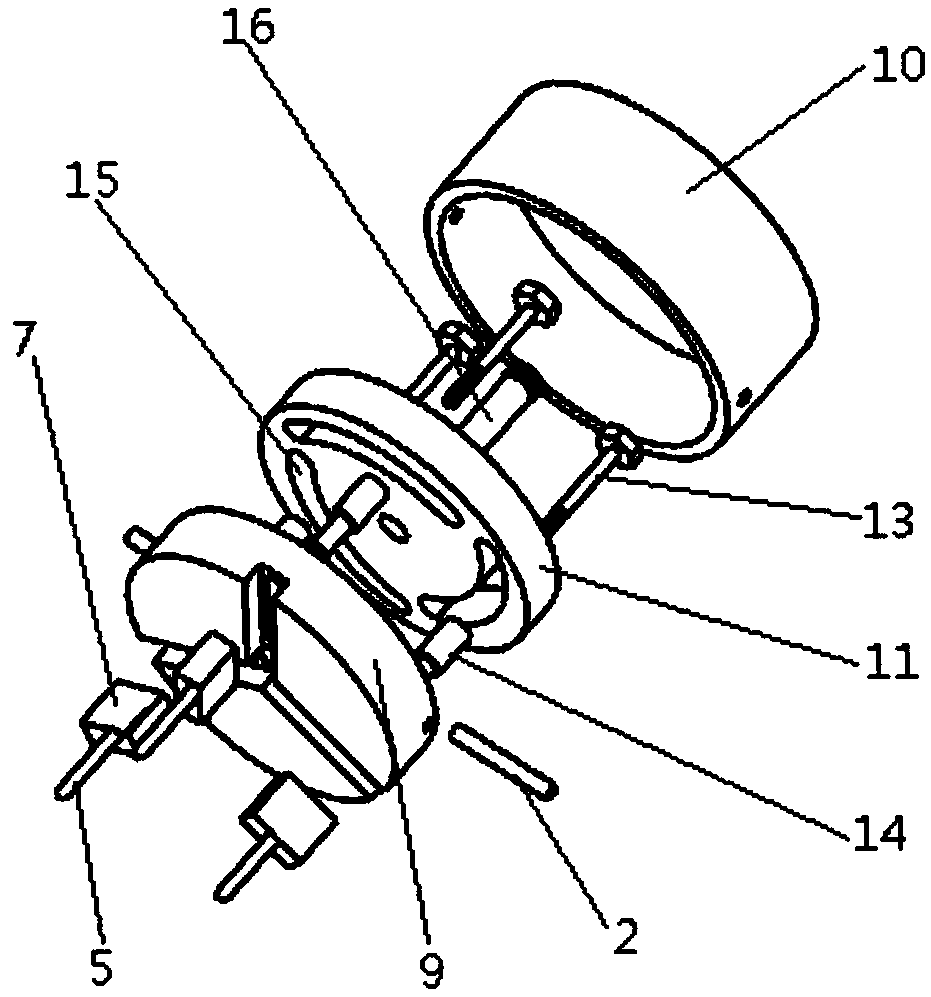

[0036] Such as Figure 1 to Figure 5 As shown, the punch clamping and positioning device includes an adjusting plate 11 , a track plate 9 , a stepped shaft 14 , a punch seat 7 and a positioning cover 10 . The positioning cover 10 is set on the outside of the adjusting disc 11 and the track disc 9, the positioning cover 10 is fixedly connected with the track disc 9 through the pin 2, and the positioning cover 10 and the track disc 9 are interference fit. The positioning cover 10 and the adjusting disc 11 are separated from each other.

[0037] There are three stepped shafts 14, three punch seats 7, and a punch punch 5 is respectively ...

Embodiment 2

[0048] The structure of this embodiment is the same as that of Embodiment 1, the only difference lies in the control aspect, specifically, when the micro stamping equipment in the present invention is used for processing such as Figure 8 For the workpiece to be processed as shown, the control process of embodiment 2 is more than that of embodiment 1, with one more control process for the conversion of punching position.

[0049] Such as Figure 8 As shown, the workpiece to be processed is compared with Figure 6 For the workpiece to be processed, there are three more rows of stamping holes 19 that need to be stamped. Therefore, the micro stamping equipment of the present invention is used for such as Figure 8 When the workpiece to be processed shown is processed, with the rotation of the adjustment disc 11, the punch punch 5 is first driven to move horizontally along the direction A. When the stepped shaft 14 moves to the limit position of the motion track groove 18 or when...

Embodiment 3

[0051] The structure of this embodiment is the same as that of Embodiment 1, the only difference lies in the control aspect, specifically, when the micro stamping equipment in the present invention is used for processing such as Figure 9 For the workpiece to be processed as shown, the control process of embodiment 3 has one more control process for punching position conversion than the control process of embodiment 1.

[0052] Such as Figure 9 As shown, the workpiece to be processed is compared with Figure 8 For the workpiece to be processed, there are three more rows of stamping holes 19 that need to be stamped. Therefore, the micro stamping equipment of the present invention is used for such as Figure 9 When the workpiece to be processed shown is processed, with the rotation of the adjustment disc 11, the punch punch 5 is first driven to move horizontally along the direction A. When the stepped shaft 14 moves to the limit position of the motion track groove 18 or when t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com