Mold telescopic positioning device

A telescopic positioning and mold technology, used in positioning devices, feeding devices, storage devices, etc., can solve the problems of the positioning plate losing positioning function, unable to accurately position, affecting the quality of plate forming, etc., to facilitate installation and debugging, reduce labor Strength, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

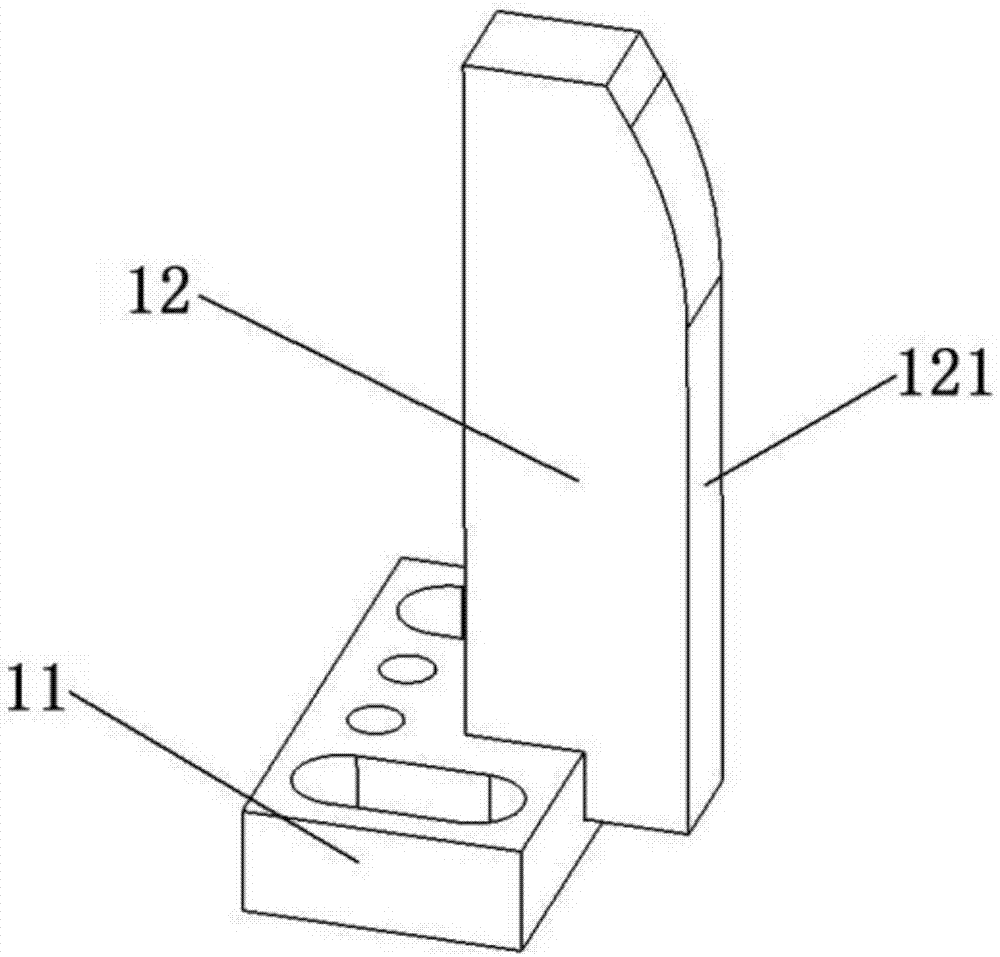

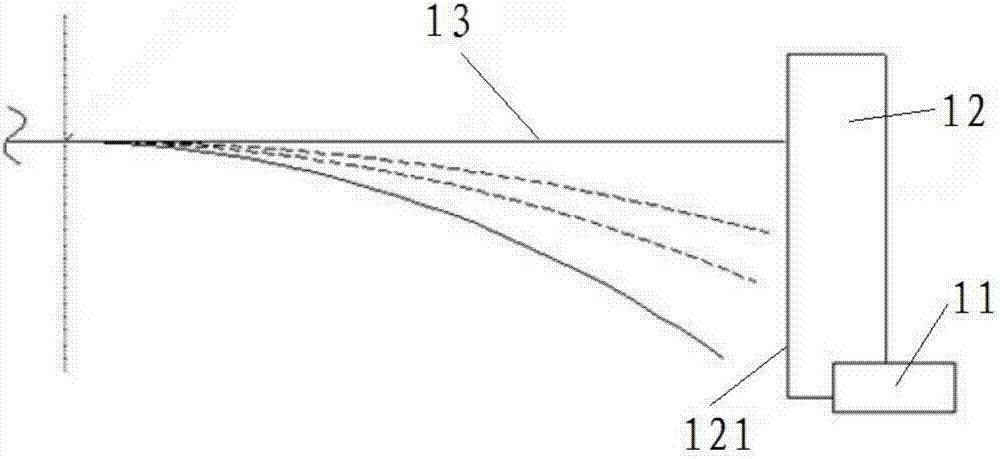

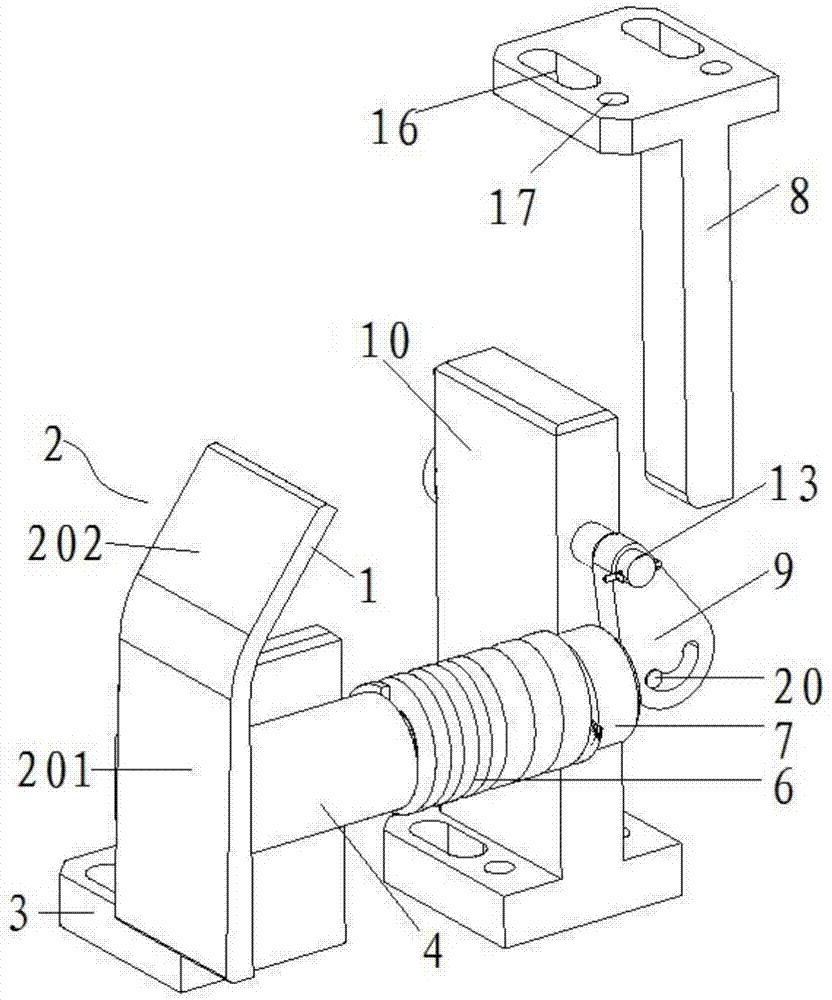

[0025] The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

[0026] Such as Figure 3 to Figure 5 As shown, the embodiment of the present invention provides a mold retractable positioning device, including: a positioning plate 1, formed with a positioning surface 2; a driving mechanism, connected with the positioning plate 1, driving the positioning plate 1 to approach or move away from The blank 21 is such that the positioning surface 2 is always in close contact with the blank 21 during the stamping process, and the positioning surface 2 is far away from the blank 21 after the stamping is completed.

[0027] The stamping worker or the feeder sends the blank 21 to the punch of the lower die base, the positioning plate 1 only performs rough positioning, and the driving mechanism drives the positioning plate 1 close to the blank 21 until it is close to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com