Lifting body for frame body splitting machine

A technology of splitting machine and lifting body, which is applied in the field of insect breeding, can solve the problems of stiff fingers, increased difficulty in dismantling the tray, and high labor intensity for silkworm farmers, and achieves the effect of reasonable overall structure design, stable lifting process, and increased structural strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

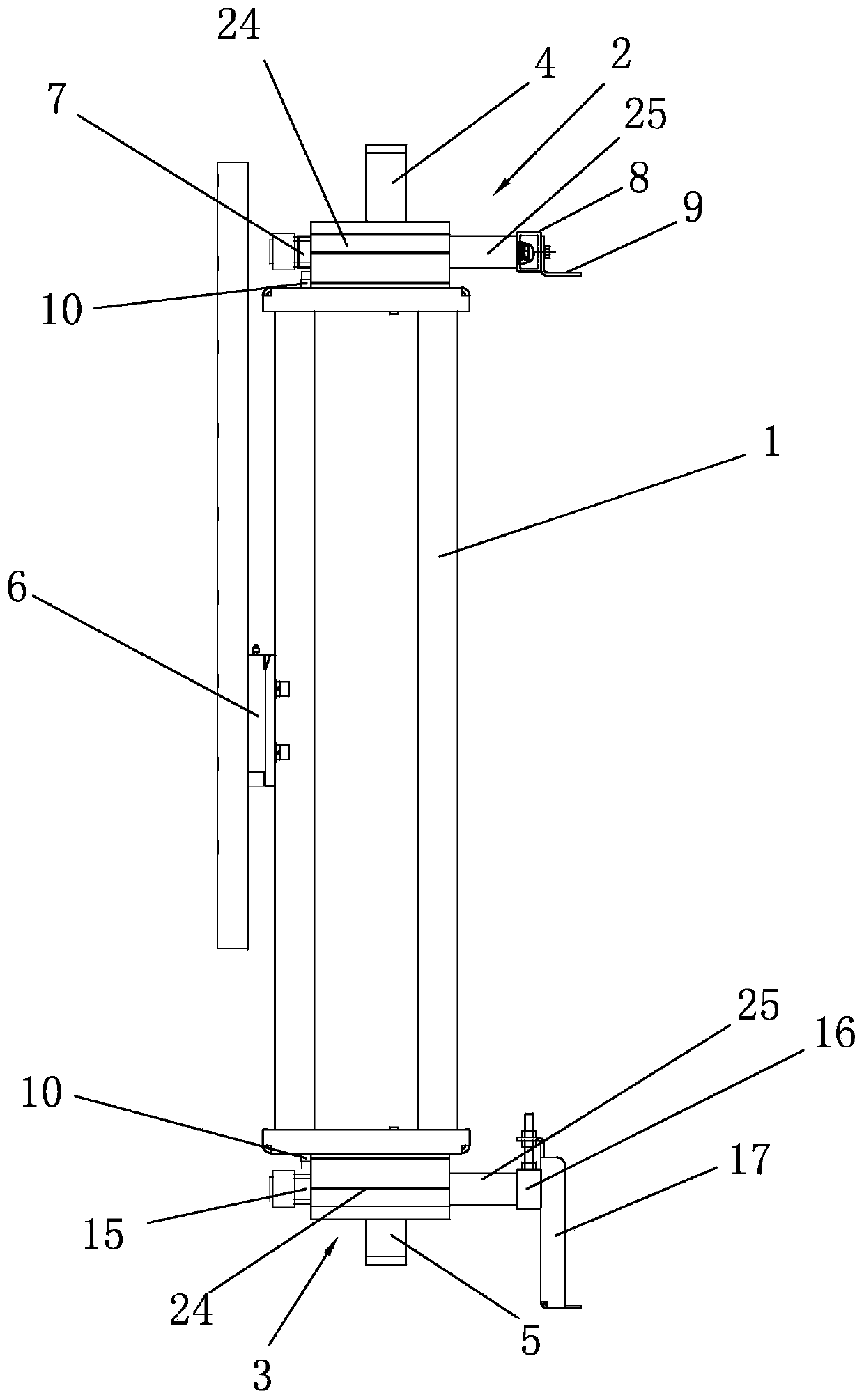

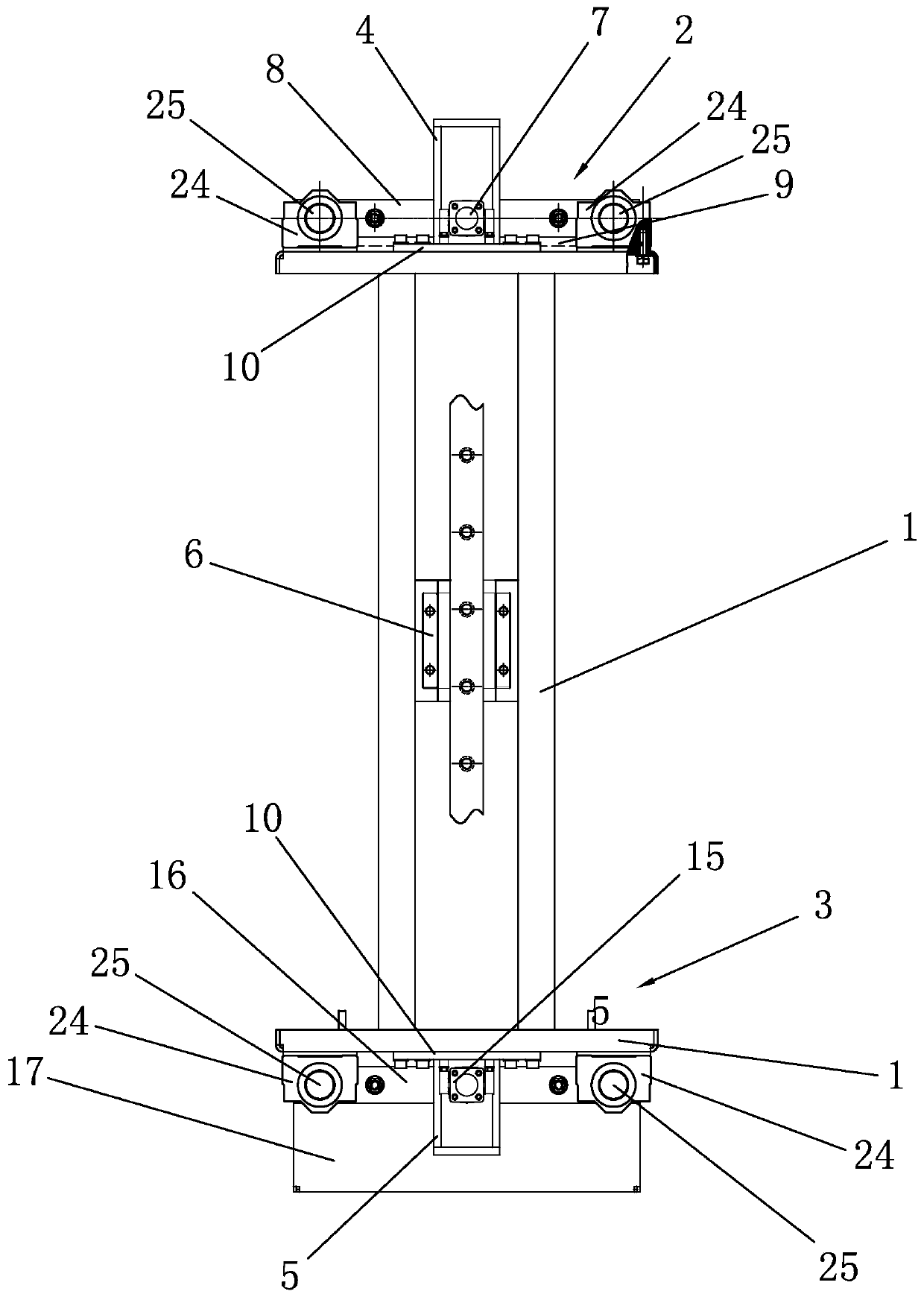

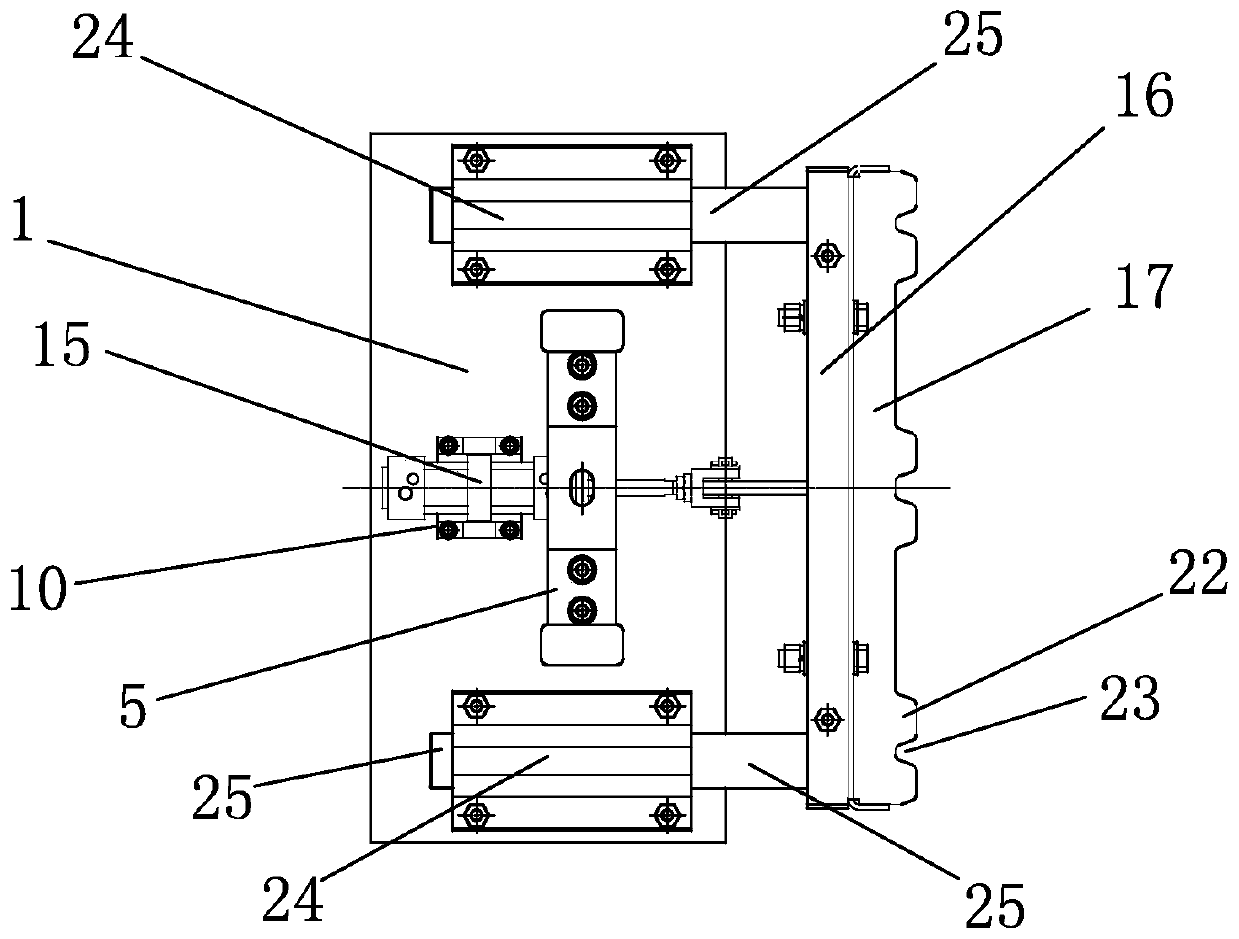

[0034] Such as Figure 1 to Figure 5 As shown, it is Embodiment 1 of the present invention, which specifically includes a frame 1 , an upper claw mechanism 2 and a lower claw mechanism 3 . The top of the frame 1 is provided with an upper support 4, the bottom of the frame 1 is provided with a lower support 5, and the left end surface of the frame 1 is provided with a linear guide rail 6. The design of the upper support 4 and the lower support 5 can increase the 1, and it is convenient for installation between the frame 1 and the chain mechanism. The design of the linear guide rail 6 makes the up and down movement of the entire lifting body more stable. In use, there will be some shaking when the chain runs, and the linear guide rail 6 can reduce the mechanical vibration amplitude during the up and down movement of the lifting body, so that the whole lifting operation is smoother and more stable.

[0035] The upper claw mechanism 2 includes a first cylinder 7, an upper push pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com