Extrusion type three-dimensional (3D) printing concrete extrusion system

A 3D printing and concrete technology, which is applied in auxiliary molding equipment, supply devices, ceramic molding machines, etc., can solve the problems that the equipment is difficult to meet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] In an exemplary embodiment of the present invention, an extrusion 3D printing concrete extrusion system is provided. In this embodiment, the size of the continuous and uninterrupted uniform printing model object is: 50 cm in length, 6 cm in width, and 12 mm in height.

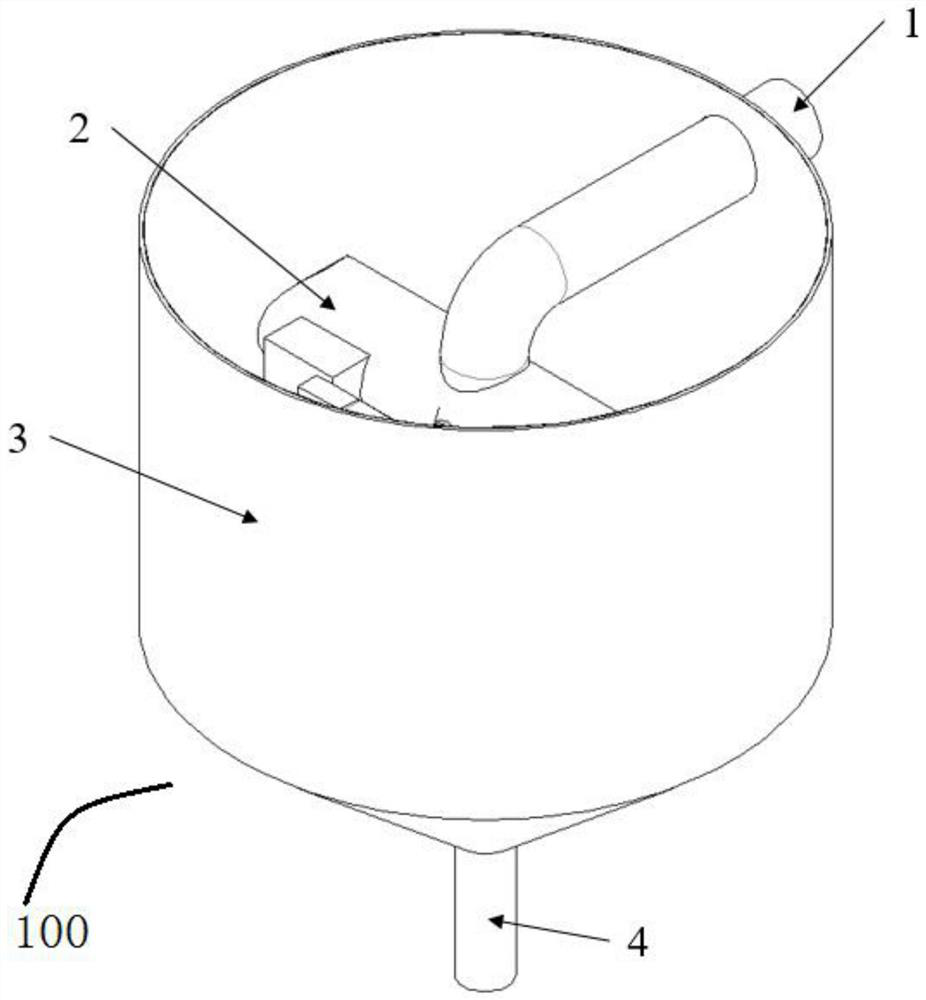

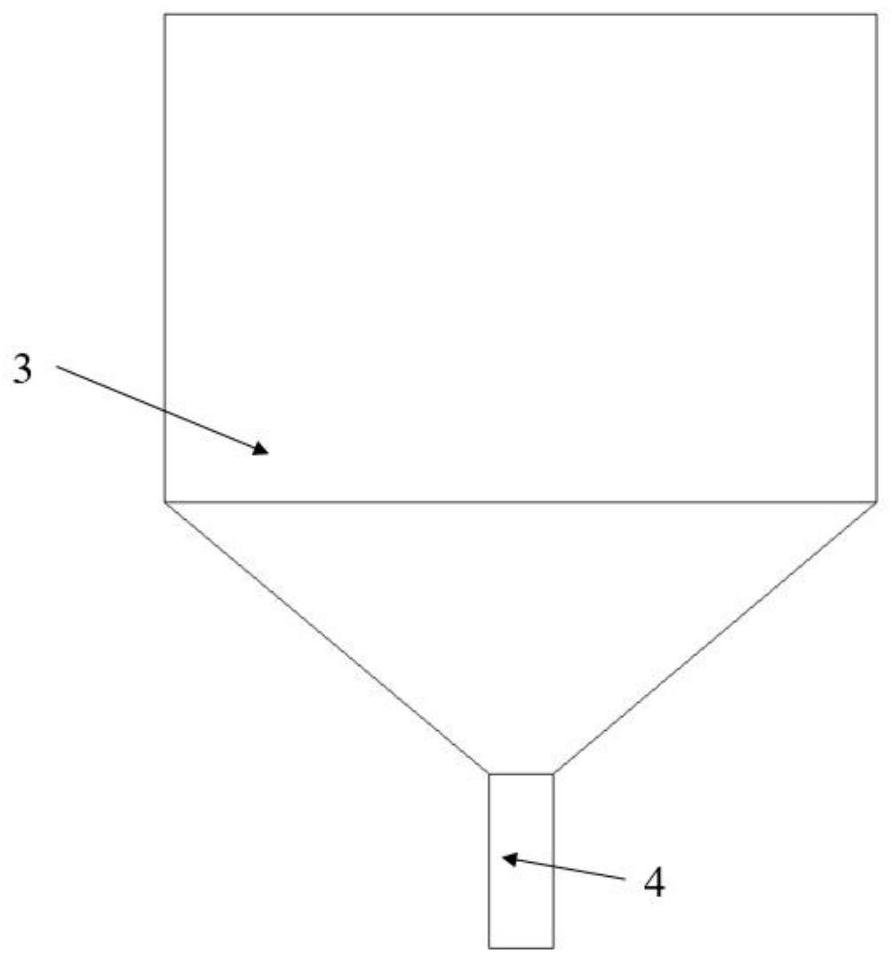

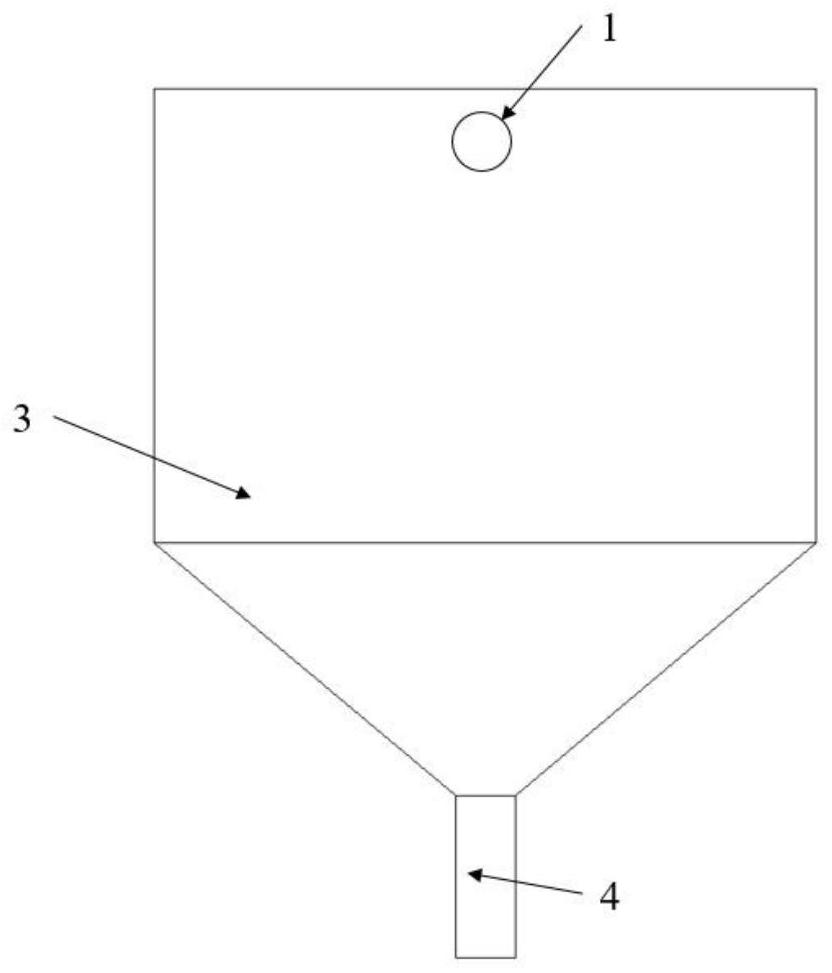

[0034]The extrusion 3D printing concrete extrusion system in this embodiment includes a feed pipe 1, an extrusion bin 2, a protective cylinder 3, a discharge pipe 4, a motor 5, a motor support plate 6, a material retaining plate 7, a feed pipe 8, Extruder 9, extruder rod fixing pipe 10, extruder rod 11 and Z-shaped transmission rod 12; protective cylinder 3 is the protective structure of the extrusion 3D printing concrete extrusion system and the support structure connected to the printer. Under the unified control of the extrusion system, the printing and molding of the extrusion extrusion system is realized; the feed pipe 1 is sealed and connected to the extrusion bin 2, the left and right ends of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com