High-precision silica gel injection mould

An injection mold, high-precision technology, applied in the field of injection molding processing, can solve the problems of taking out parts and reducing work efficiency, and achieve the effect of avoiding blockage and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with specific embodiments shown in the accompanying drawings. However, these embodiments are not limited to the present invention, and structural, method, or functional changes made by those skilled in the art according to these embodiments are included within the protection scope of the present invention.

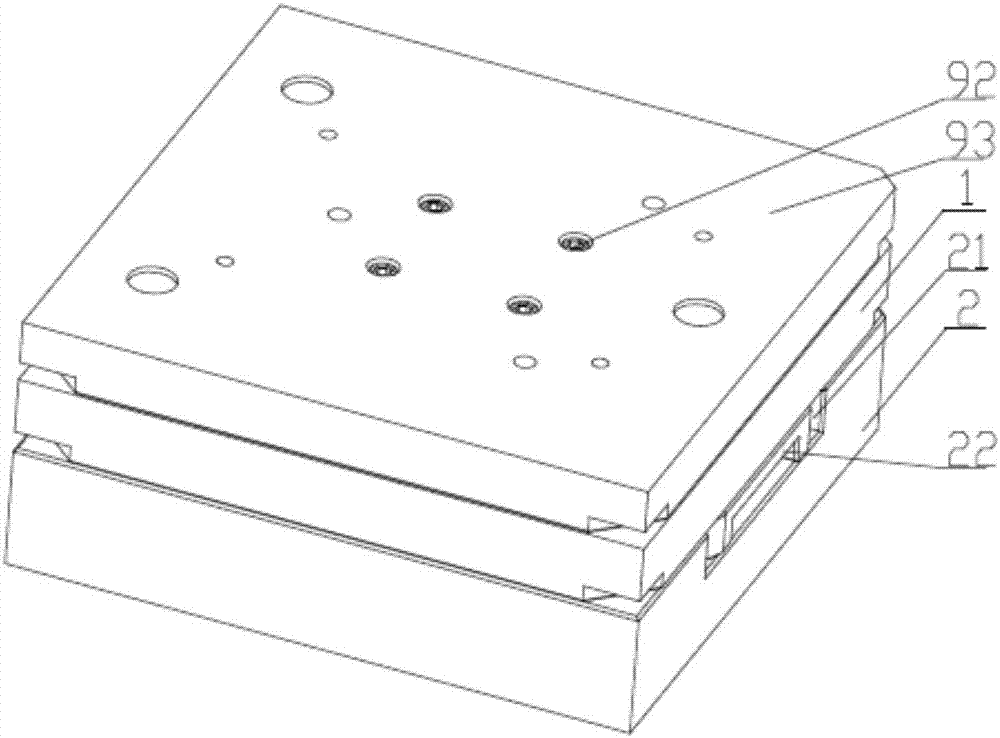

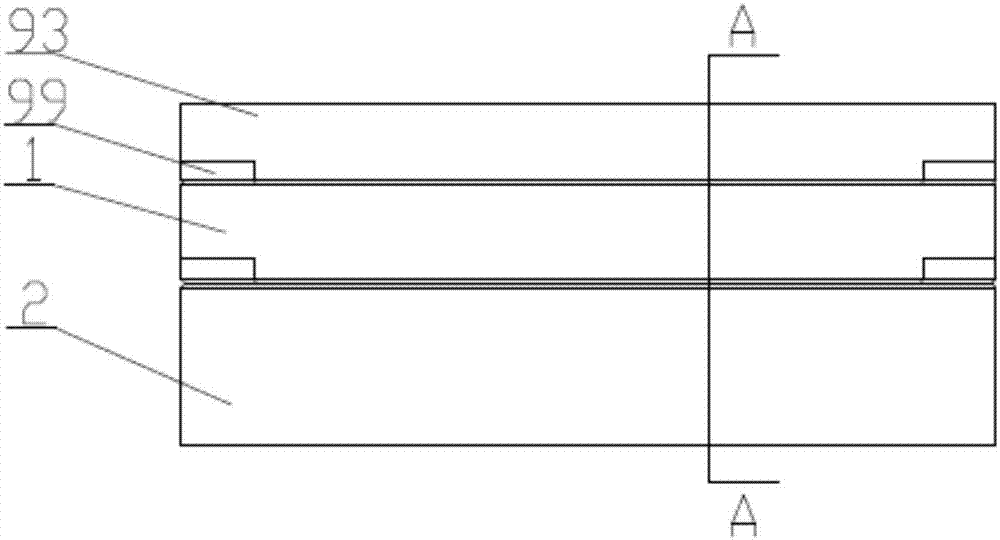

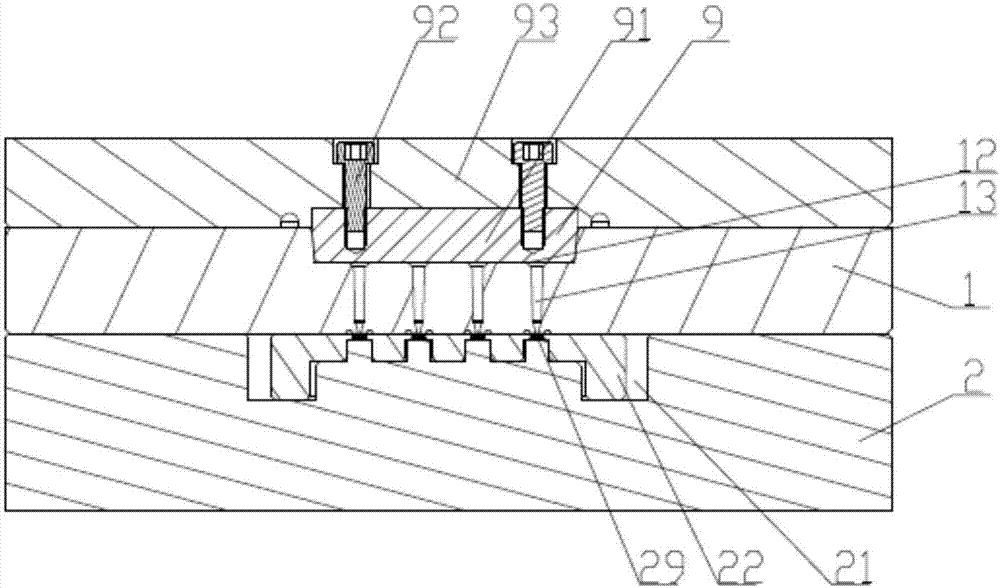

[0025] like Figure 1 to Figure 3 As shown, the present invention discloses a high-precision silicone injection mold, which at least includes an upper template 1 and a lower template 2. There is a groove 21 on the lower template 2, and a mold core 22 is arranged in the groove 21. The upper surface of the mold core 22 is at the same level as the upper surface of the lower template 2, and a first positioning mechanism 23 is provided between the mold core 22 and the lower template 2, and the first positioning mechanism 23 includes a fixed The three first protrusions 28 on the groove 21 of the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com