Integrated high-rigidity light photovoltaic cell component and photovoltaic shutter

A photovoltaic cell and high-stiffness technology, which is applied in photovoltaic power generation, photovoltaic modules, electrical components, etc., can solve the problems of low stiffness of the blade plate, affect the service life, and high cost of use, and achieve easy manufacturing and assembly, protection of bus wires, and lightening effect of weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

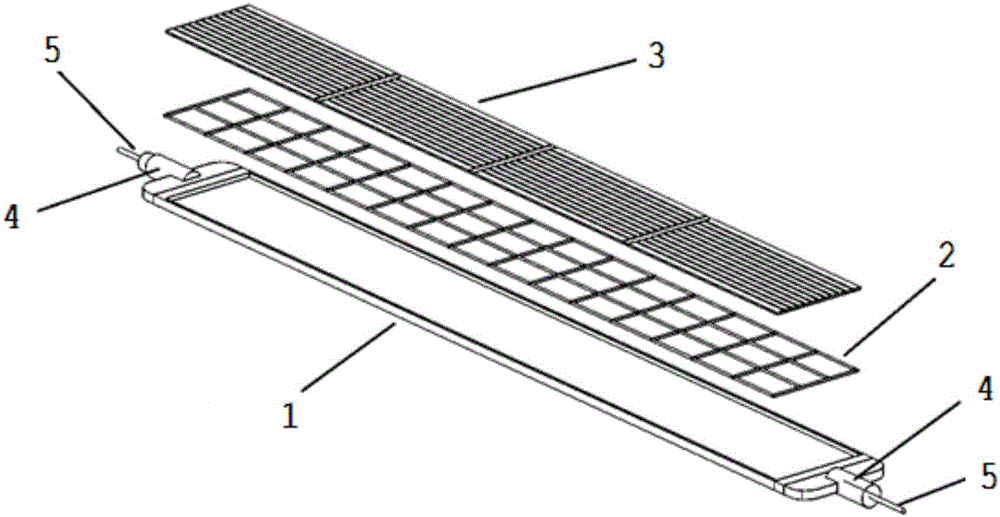

[0033] Such as figure 1 As shown, an integrated high-rigidity light-weight photovoltaic cell assembly includes photovoltaic blades arranged in a louver structure as a whole. The photovoltaic blades have a transmission shaft 4 and a bus wire 5, and the transmission shaft 4 is used for fixing and rotating the photovoltaic blades. , a single photovoltaic blade is a laminated composite structure, including a composite plastic layer 1 and a strip-shaped photovoltaic cell sheet 3 bonded to each other, a transmission shaft 4 and a bus wire 5 are arranged at both ends of the strip-shaped photovoltaic cell sheet 3, and the composite plastic layer 1 is injection-molded An integrally formed plastic layer, the prestressed steel wire mesh 2 is connected to the strip-shaped photovoltaic cells 3 by bonding.

[0034] The components of the composite plastic layer 1 are: PC+ABS.

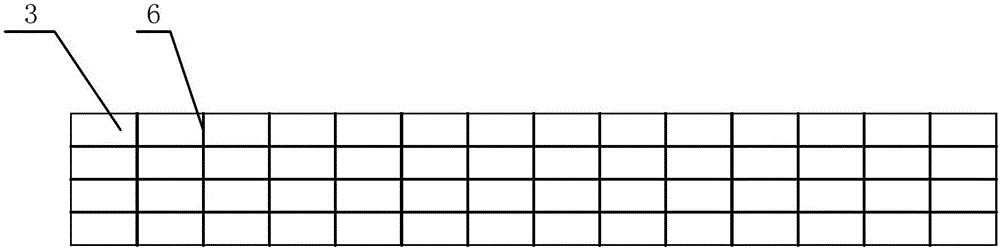

[0035] Composite plastic layer 1 has structural ribs 6, and the front view shape of structural ribs 6 is as follow...

Embodiment 2

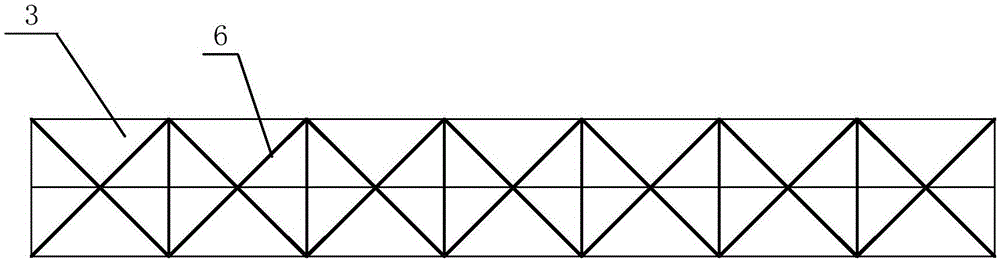

[0040] Different from Embodiment 1, the structural ribs 6 also include oblique ribs 63, the number of transverse ribs 61 is one, and the longitudinal ribs 62 divide the surface of the composite plastic layer 1 into a plurality of square grids, and the oblique ribs 63 are arranged on each square grid. The diagonal position of the grid. Specific as image 3 shown. This structure also achieves better strength.

[0041] All the other are identical with embodiment 1.

Embodiment 3

[0043] Different from Embodiment 1, the structural rib 6 is corrugated, and the corrugated stripes are parallel to the length direction of the photovoltaic blade. Specific as Figure 5 shown. The advantage of this structure is that it is easy to clean the blades, and the strength can also meet the requirements.

[0044] All the other are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com