Desktop type cement-based material 3D printer

A technology of cement-based materials and 3D printers, applied in the direction of additive processing, ceramic molding machines, auxiliary molding equipment, etc., to achieve the effect of ensuring safety and reliability, high speed, high-precision printing and fast printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Specific examples of the present invention are given below. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the claims of the present application.

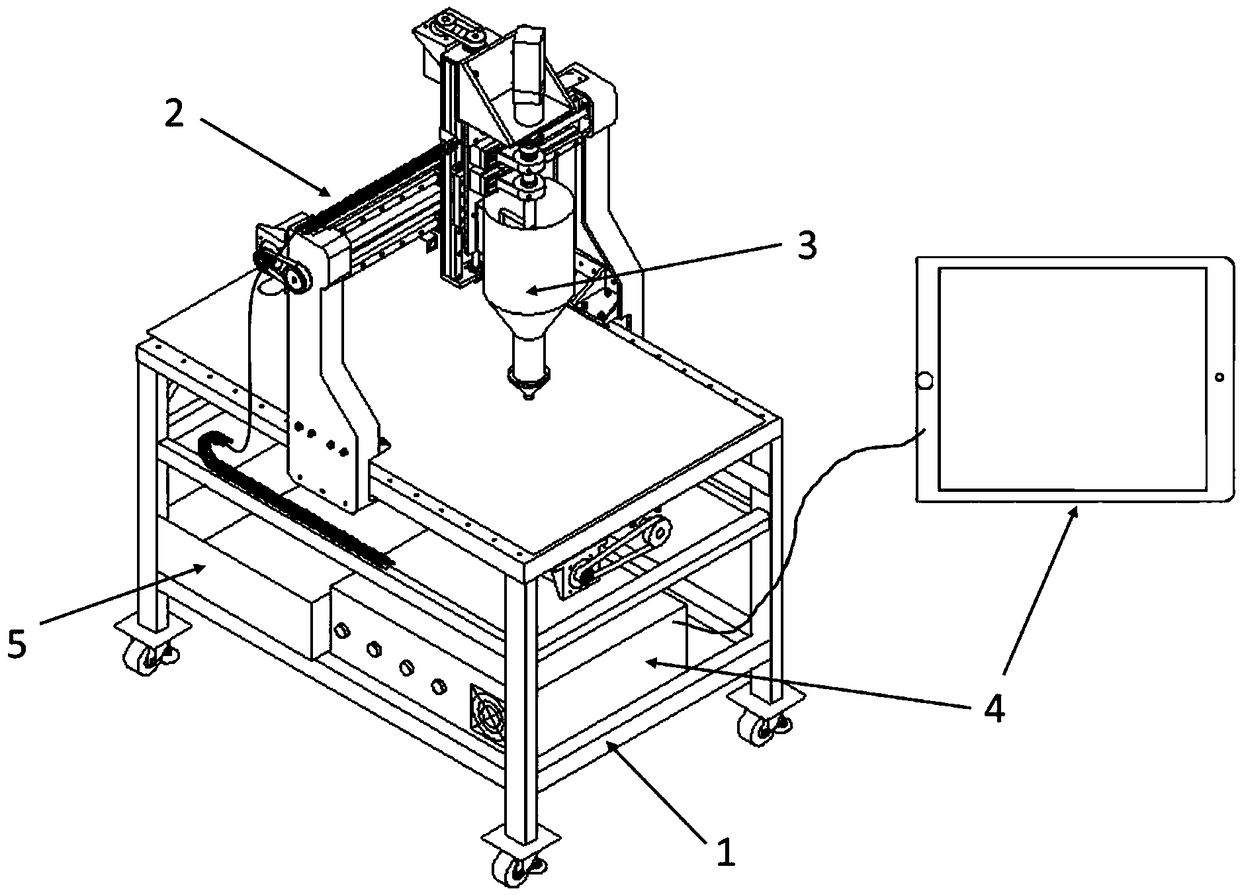

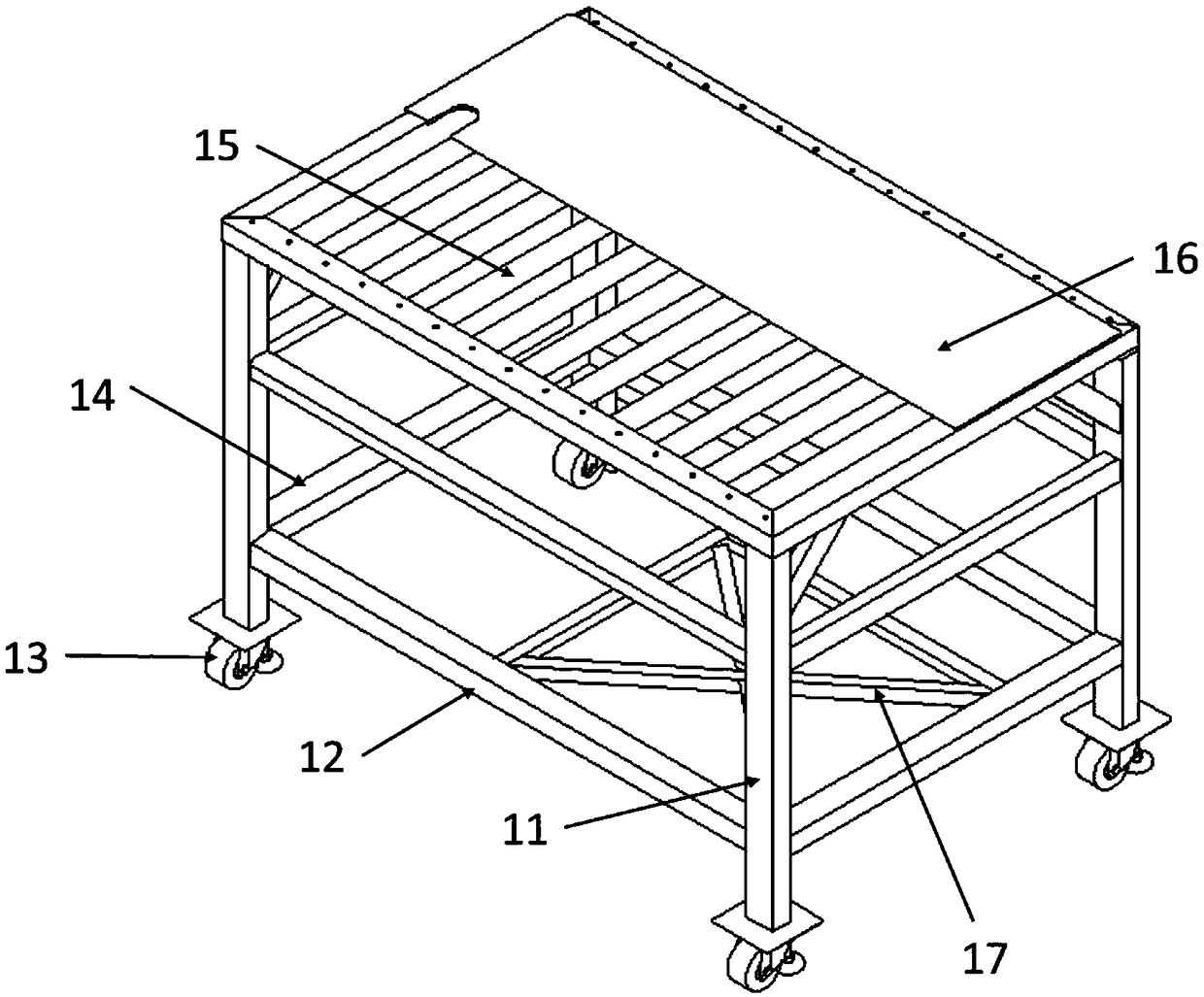

[0034] The invention provides a desktop cement-based material 3D printer (printer for short, see Figure 1-8 ), characterized in that the printer includes a main frame 1, a mobile system 2, an extrusion system 3 and a control system 4; the main frame 1 is a main support structure; the mobile system 2 and the control system 4 are installed on the main frame 1, and the extrusion Material system 3 is installed on mobile system 2;

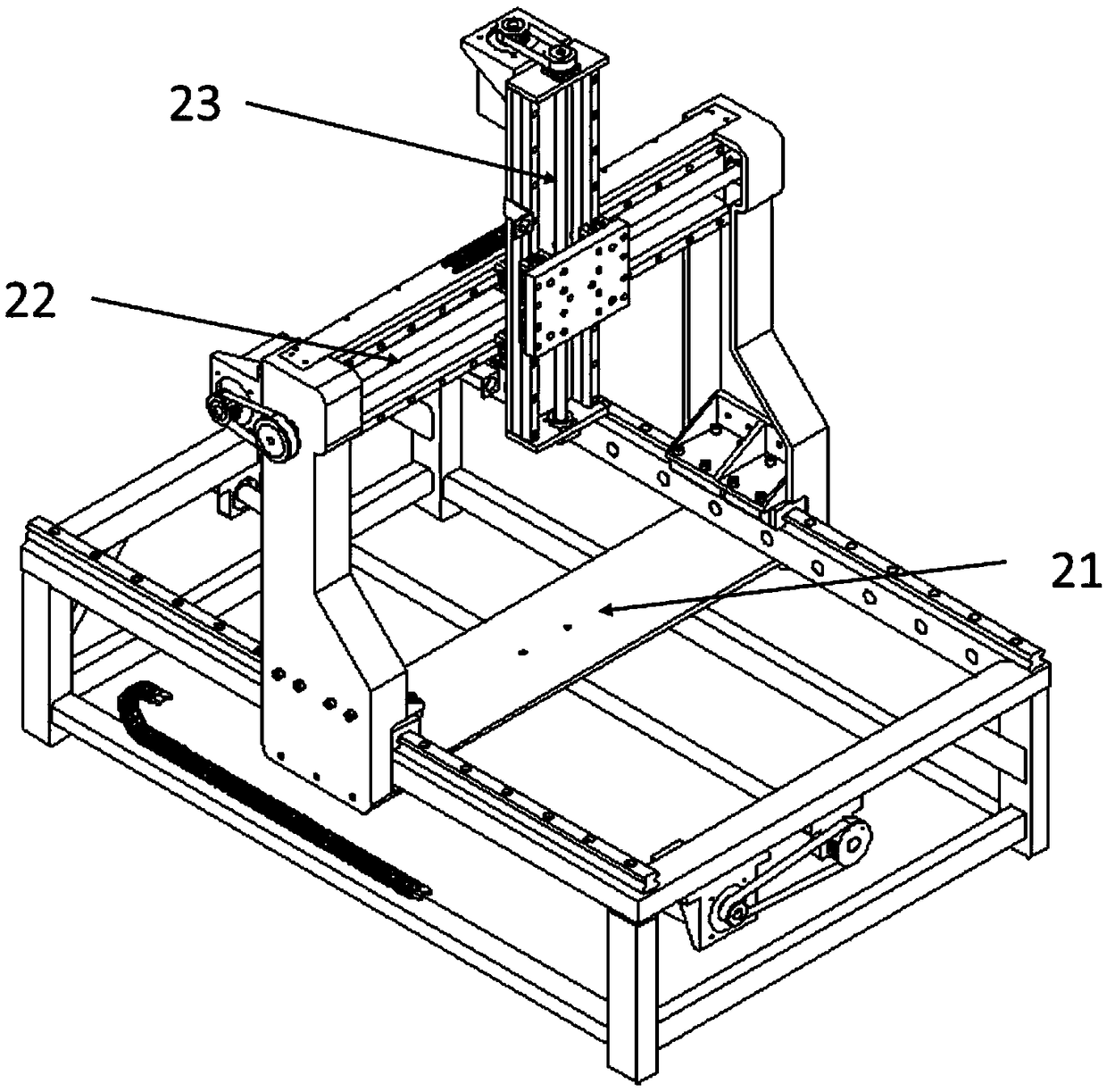

[0035] The moving system 2 includes an x-axis moving mechanism 21, a y-axis moving mechanism 22 and a z-axis moving mechanism 23; the x-axis moving mechanism 21 is installed on the main frame 1, and the y-axis moving mechanism 22 is installed on the x-axis moving mechanism 21 Above, the z-axis moving mechanism 23 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com