A printer for printing Hunan embroidery cloth

A technology for printers and embroidered cloth, applied to typewriters, printing devices, printing, etc., to achieve the effects of avoiding skew, reasonable structural design, and reducing pollution emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

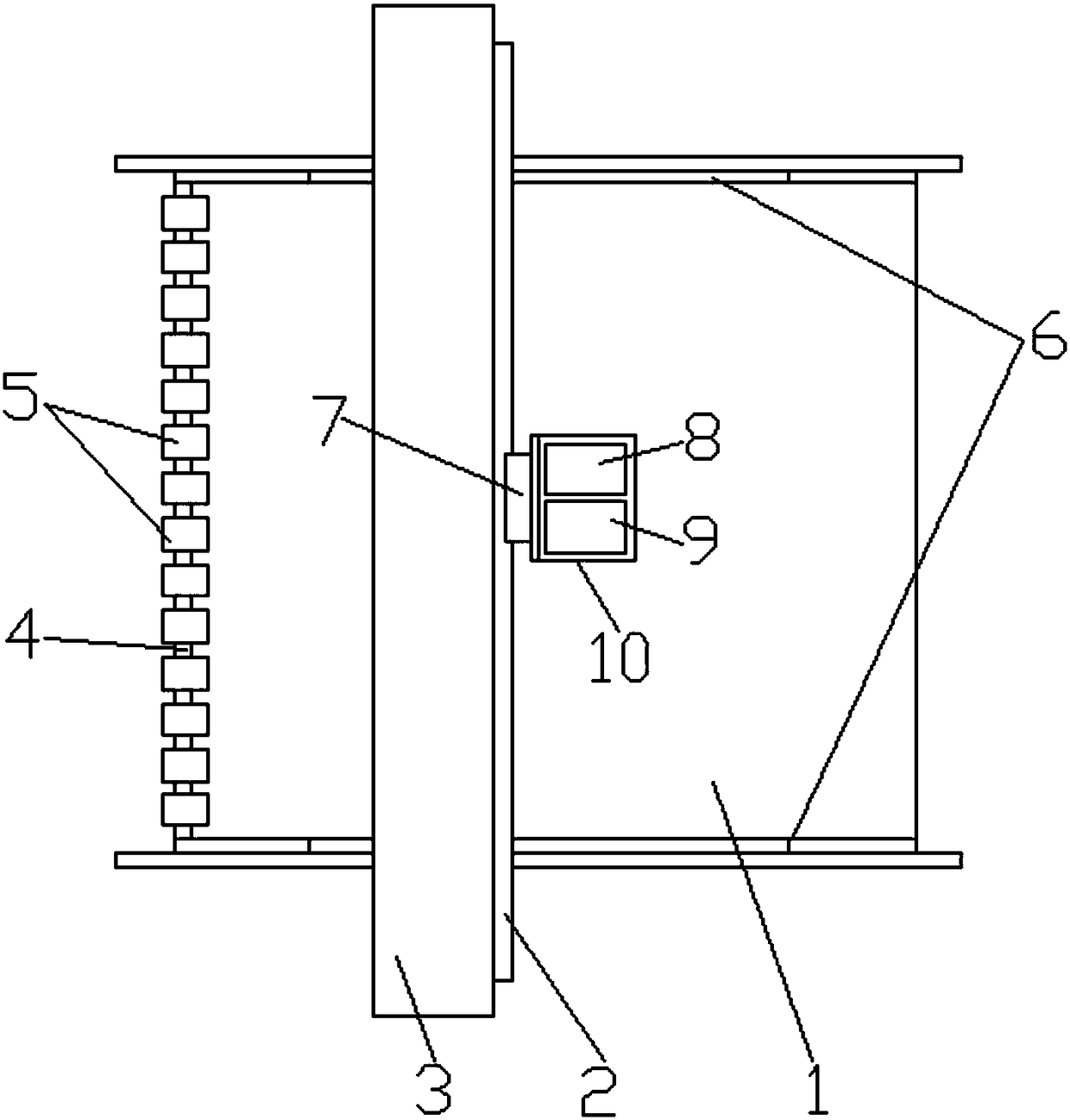

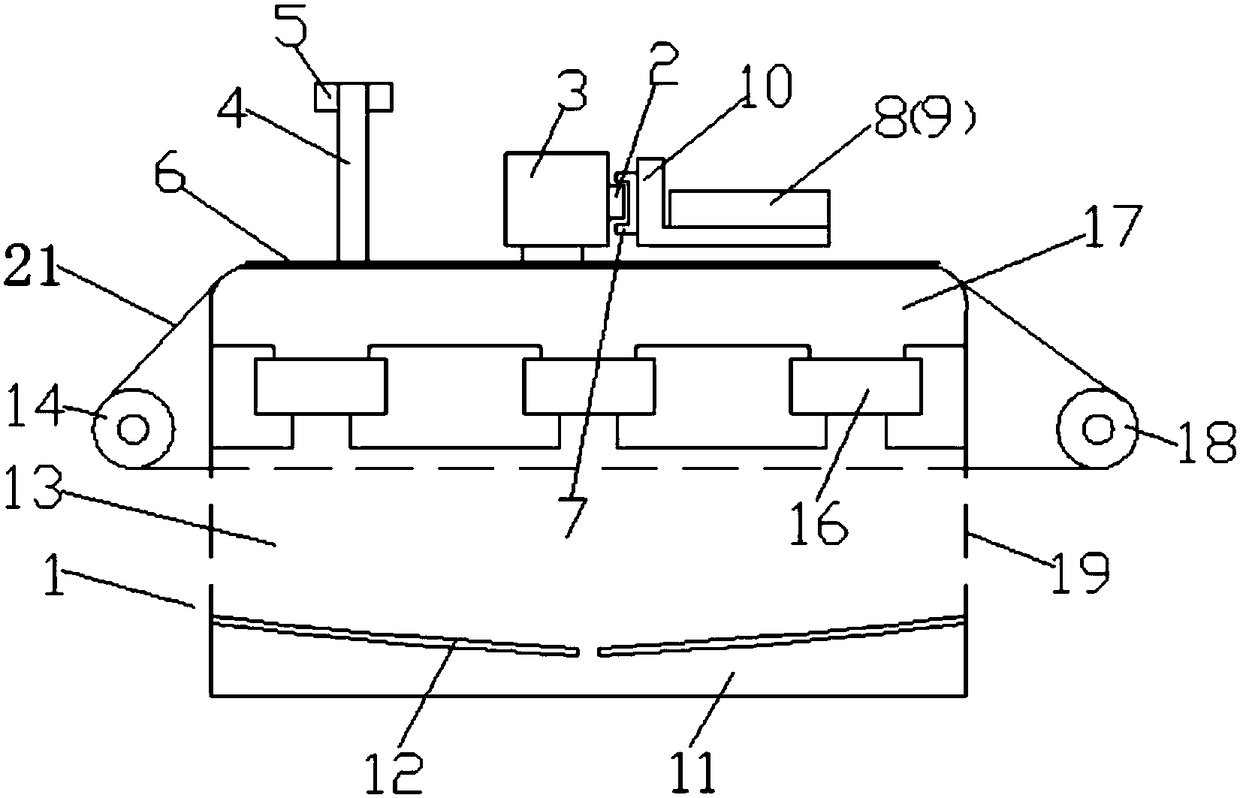

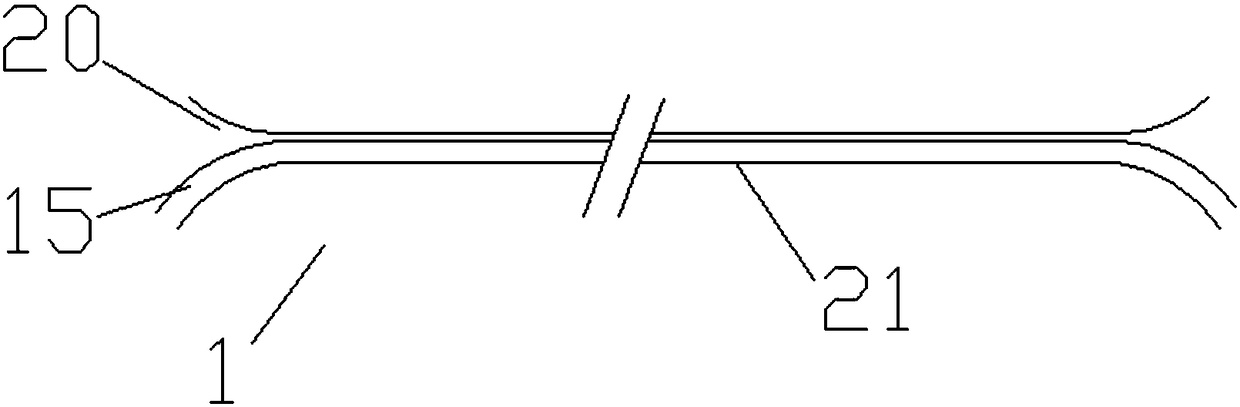

[0031] refer to Figure 1-4 , a kind of printer that is used for the printing of Hunan embroidery embroidered cloth, comprises the computer that is installed with Xiangxiu embroidered cloth pattern processing software, frame 1, guide belt type digital printing machine and several cameras 5 that are fixed on the frame 1 by camera mounting bracket 4 The belt-guiding digital printing machine includes a driving roller device 18, a driven roller device 14, an endless guide belt 21 sleeved on the driving roller device 18 and the driven roller device 14, a guide rail 2, a beam 3, a slider 7, and a nozzle frame 10 and inkjet printing head, the guide rail 2 is fixed on the beam 3, the slider 7 is movably connected on the guide rail 2, the nozzle frame 10 is fixed on the slider 7, and the inkjet printing head is installed on On the nozzle frame 10, several cameras 5 are arranged in a row, the arrangement direction is parallel to the beam 3, and the annular guide belt 21 is grid-like;

...

Embodiment 2

[0039] The difference from Embodiment 1 is that in this embodiment, the inkjet print head includes an inkjet print head group one 8 and an inkjet print head group two 9, and the inkjet print head group one 8 adopts water-soluble Ink, the inkjet printing head group 2 9 adopts water-insoluble ink. The inkjet printhead group one 8 is made up of cyan, magenta, yellow and black nozzles; the inkjet printhead group two 9 is also made up of cyan, magenta, yellow and black nozzles. Nozzle composition. Two sets of inkjet printing heads are set on the same set of guide rails of the same beam, and these two sets of inkjet printing heads can respectively use two types of ink, one is water-soluble ink and the other is non-water-soluble ink , especially suitable for synchronous printing of embroidery samples and background patterns of Hunan embroidery; the structure design is reasonable.

Embodiment 3

[0041] The difference with Embodiment 1 is that in this embodiment, the volume capacity of the air chamber one 13 is three times that of the air chamber two 17, ensuring that the air chamber is prevented from being damaged on the basis of using less manufacturing materials. The accumulative air volume of the first chamber leads to gas backflow and reduces the air collection effect of the air chamber two, thereby reducing the bonding effect of the embroidered cloth and the annular guide belt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com