A method of manufacturing an embedded self-defogging and zooming microlens array, its product and its application

A micro-lens array, embedded technology, applied in lenses, manufacturing, manufacturing tools, etc., can solve problems such as difficult to achieve rapid zoom, fogging, icing, etc. simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

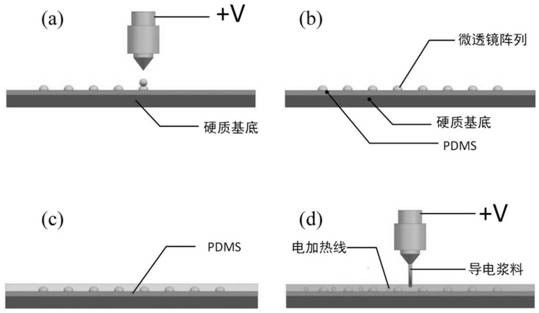

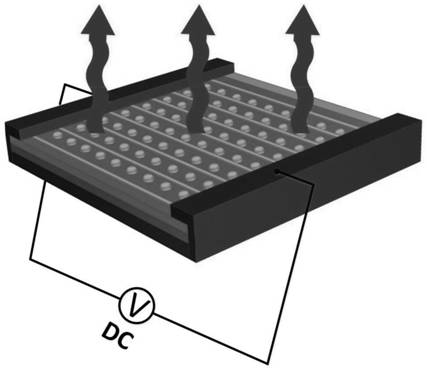

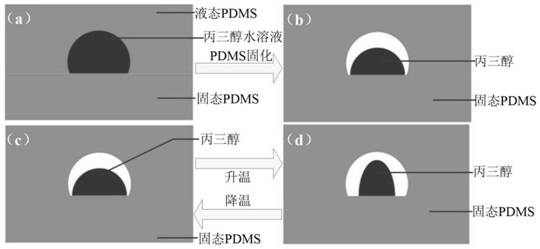

[0044] Step 1: Prepare the printing substrate

[0045] (1) Choose ordinary glass as the hard substrate, first place the ordinary glass in isopropanol solution for ultrasonic cleaning for 5 minutes, then place it in deionized water for ultrasonic cleaning for 5 minutes, and finally dry it with nitrogen, take it out for use;

[0046] (2) The PDMS liquid is Sylgard 184 from Dow Corning Company, and the PDMS elastomer and its corresponding curing agent are stirred and mixed evenly at a mass ratio of 10:1, and placed in a vacuum drying oven to evacuate to remove air bubbles;

[0047] (3) Pour the vacuum-treated PDMS liquid on the surface of ordinary glass, let it stand for 2 minutes, and then place it on a coater for spin coating. The spin coating time is 2 minutes, and the rotation speed is 500r / min to form a layer of PDMS liquid about 50 μm thick. Finally, place it in a vacuum drying oven and heat it at 70°C for 30 minutes, the PDMS will be cross-linked and cured by heating, and ...

Embodiment 2

[0056] Step 1: Prepare the printing substrate

[0057] (1) Choose a silicon wafer as the hard substrate, first clean the silicon wafer with isopropanol solution for 5 minutes, then place it in deionized water for 5 minutes to remove the residual isopropanol solution, and finally dry it with nitrogen, take it out for use ;

[0058] (2) Select Sylgard 184 from Dow Corning as the PDMS liquid, stir and mix the PDMS elastomer and curing agent at a ratio of 10:1, and place in a vacuum drying oven to evacuate to remove air bubbles;

[0059] (3) Pour the vacuum-treated PDMS liquid on the surface of the silicon wafer, spin-coat it with a coating machine, spin-coat for 2 minutes, and rotate at a speed of 500r / min to form a layer of PDMS liquid about 50 μm thick; finally place it in vacuum drying Heating in the box at 75°C for 30 minutes, the PDMS is heated to cross-link and solidify, and the printing substrate is prepared;

[0060] Step 2: Print Microlens Array

[0061] (1) Select 60...

Embodiment 3

[0071] Step 1: Prepare the printing substrate.

[0072] (1) Select high-quality float glass as the hard substrate, first place the float glass in isopropanol solution for ultrasonic cleaning for 5 minutes, then place it in deionized water for ultrasonic cleaning for 5 minutes, and finally dry it with nitrogen, take it out for use;

[0073] (2) The PDMS liquid is Sylgard 184 from Dow Corning Company. The PDMS elastomer and its corresponding curing agent are stirred and mixed evenly at a ratio of 10:1, and placed in a vacuum drying oven to evacuate to remove air bubbles;

[0074] (3) Pour the vacuum-treated PDMS liquid on the surface of the float glass, let it stand for 2 minutes, and then place it on a homogenizer for spin coating. The spin coating time is 1 min, and the speed is 500r / min to form a layer of PDMS liquid about 80 μm thick. . Finally, it was placed in a vacuum drying oven and heated at 75°C for 30 minutes. The PDMS was heated to cross-link and solidify, and the pri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com