Continuous moldless forming device and method for metal bellows

A metal bellows, dieless forming technology, applied in the storage device, feeding device, positioning device and other directions, can solve the problem of inability to realize the processing and forming of long-distance bellows in the axial direction, and achieve simple structure, low cost, and widen application. field effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

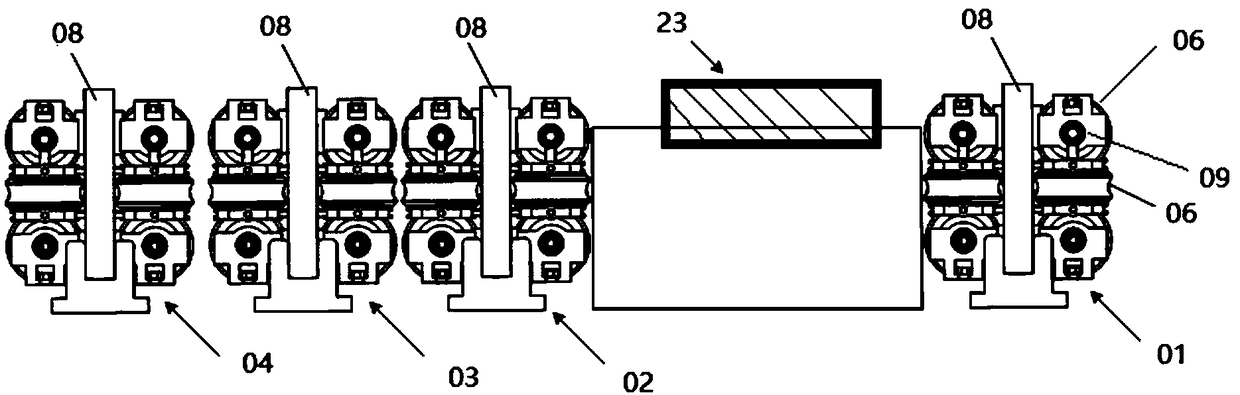

[0052] The continuous moldless forming device of metal bellows in this embodiment includes: at least one first metal pipe feeding assembly (such as figure 1 No. 1 roll box 01 structure shown in), metal tube corrugation forming assembly, at least one third metal tube feeding assembly (such as figure 1 structure of No. 2 roll box 02 and No. 3 roll box 03) and at least one second metal tube feed assembly (such as figure 1The structure of No. 4 roller box 04 shown in);

[0053] In this embodiment, the first metal pipe feeding assembly is used to feed the metal pipe at the first feeding speed; the second metal pipe feeding assembly and the third metal pipe feeding assembly are used to feed the metal pipe at the second feeding speed Metal tube; the first feed rate is greater than the second feed rate. The axial compression force of the metal tube during the corrugation process can be provided by means of different feed speeds.

[0054] The metal pipe feeding assembly in this embo...

Embodiment 2

[0069] The following combination Figure 1 to Figure 3 A continuous dieless forming device for metal bellows will be described in detail.

[0070] The continuous moldless forming device of metal bellows in this embodiment includes: a first metal pipe feeding assembly (namely No. 1 roller box 01), a metal circular pipe corrugation forming assembly 23, two third metal pipe feeding assemblies ( Such as figure 1 No. 2 roll box 02, No. 3 roll box 03), a second metal tube feed assembly.

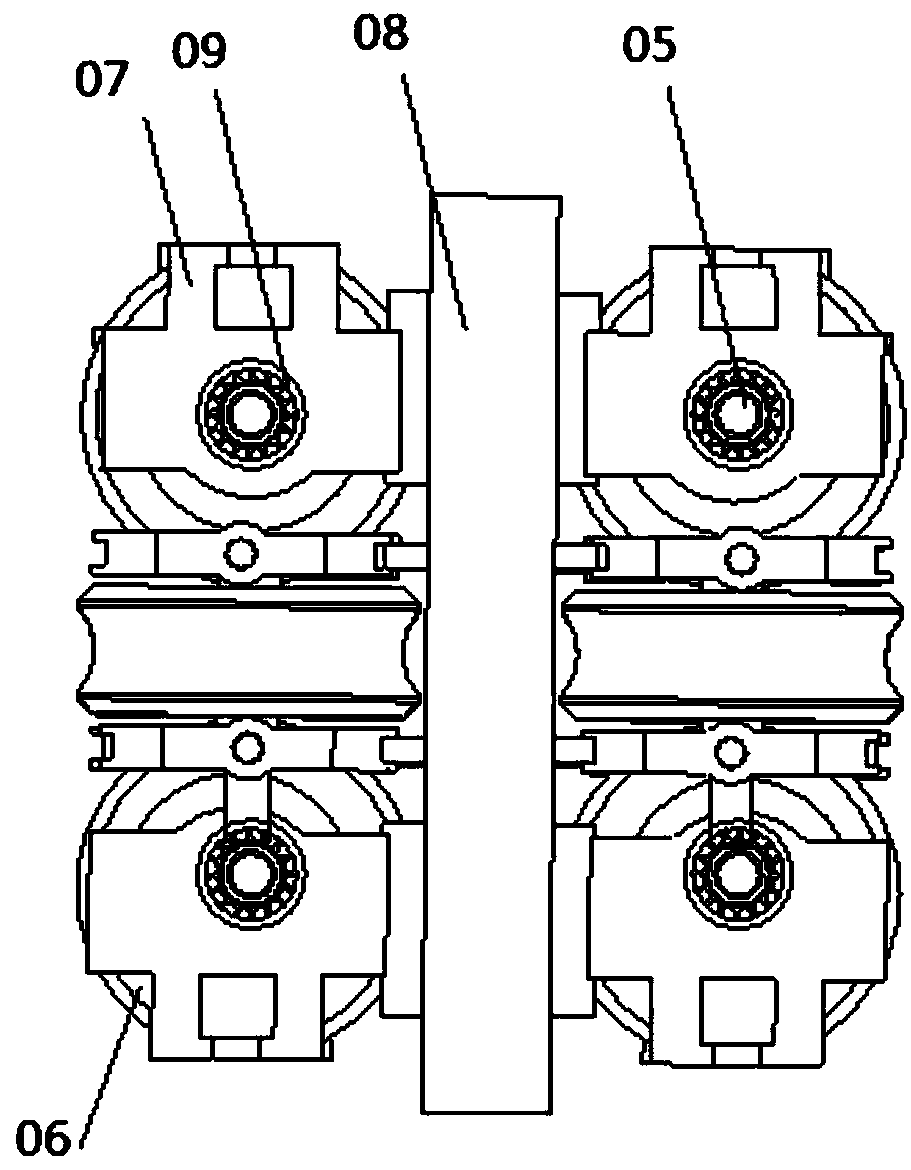

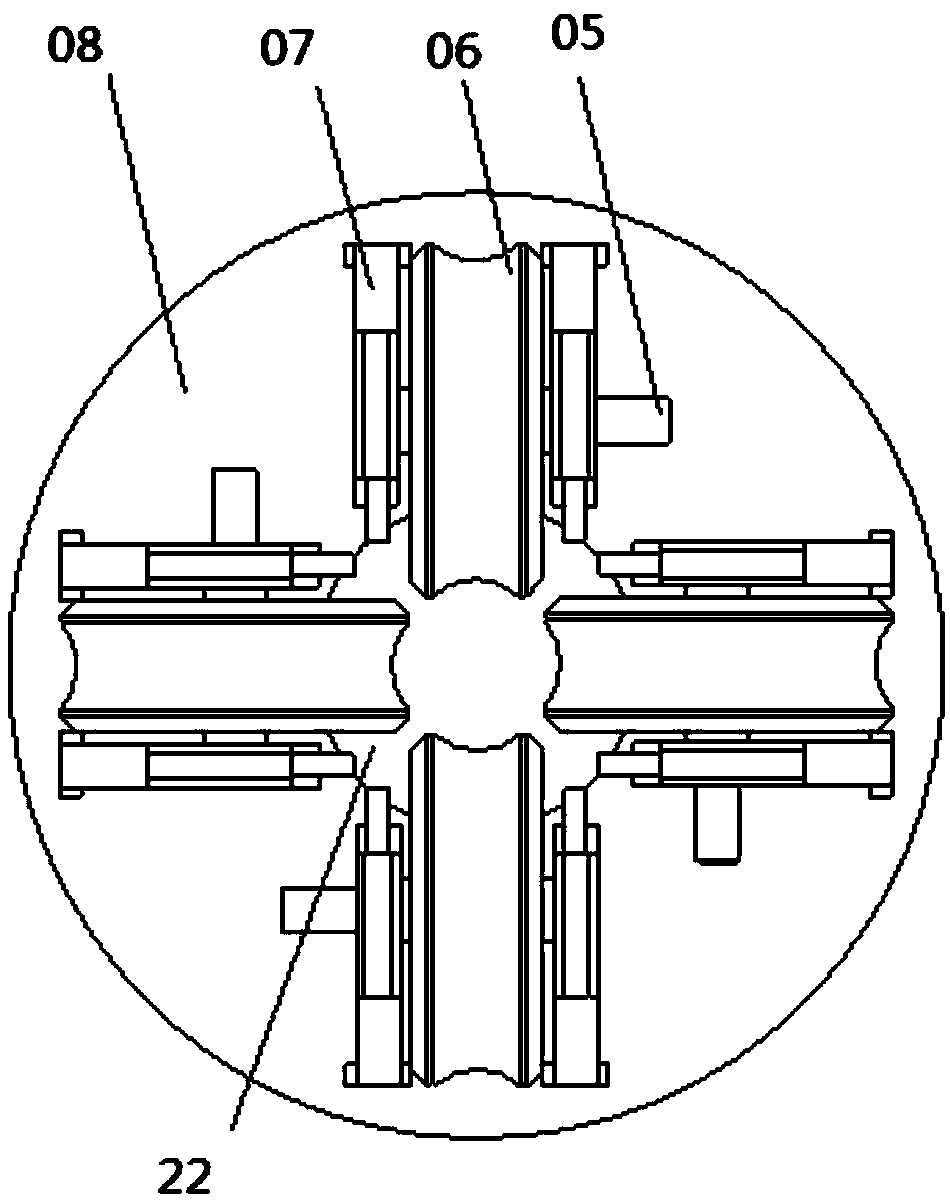

[0071] No. 1 roll box 01 to No. 4 roll box 04 are respectively provided with their own feed end and discharge end; wherein, the feed end of each roll box corresponds to a group of evenly distributed nip rollers, and the discharge end of each roll box Corresponding to a group of evenly distributed pinch rollers. Along the feeding direction of the metal pipe, there are uniformly distributed pinch rollers 11 at the feed end of the No. 1 roll box, uniformly distributed pinch rolls 12 at the discharg...

Embodiment 3

[0095] This embodiment provides a method for forming the continuous moldless forming device described in Embodiment 1, the method includes:

[0096] Step A01, passing one end of the metal pipe sequentially through the first metal pipe feeding assembly, the metal pipe forming assembly, the third metal pipe feeding assembly and the second metal pipe feeding assembly, and making the first metal pipe feeding assembly and the second metal pipe feeding assembly Two metal tube feed assemblies grip the metal tube.

[0097] At this time, the first metal pipe feeding assembly and the second metal pipe feeding assembly are in a clamped state.

[0098] Step A02, the metal tube corrugation forming component performs circumferential heating on a selected local heating position on the metal tube, forms an annular heating area on the metal tube, and simultaneously performs circumferential heating on both sides of the annular heating area on the metal tube. cool down.

[0099] In this step, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com