Fracturing fluid blending device

A fracturing fluid and compounding technology, applied in the directions of mixing method, transportation and packaging, gas/vapor and solid mixing, etc., can solve the problems of long use viscosity time, shorten the viscosity increase time, environmental pollution, etc., and achieve the fracturing cycle. The effect of shortening, improving fracturing operation efficiency, and safe and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

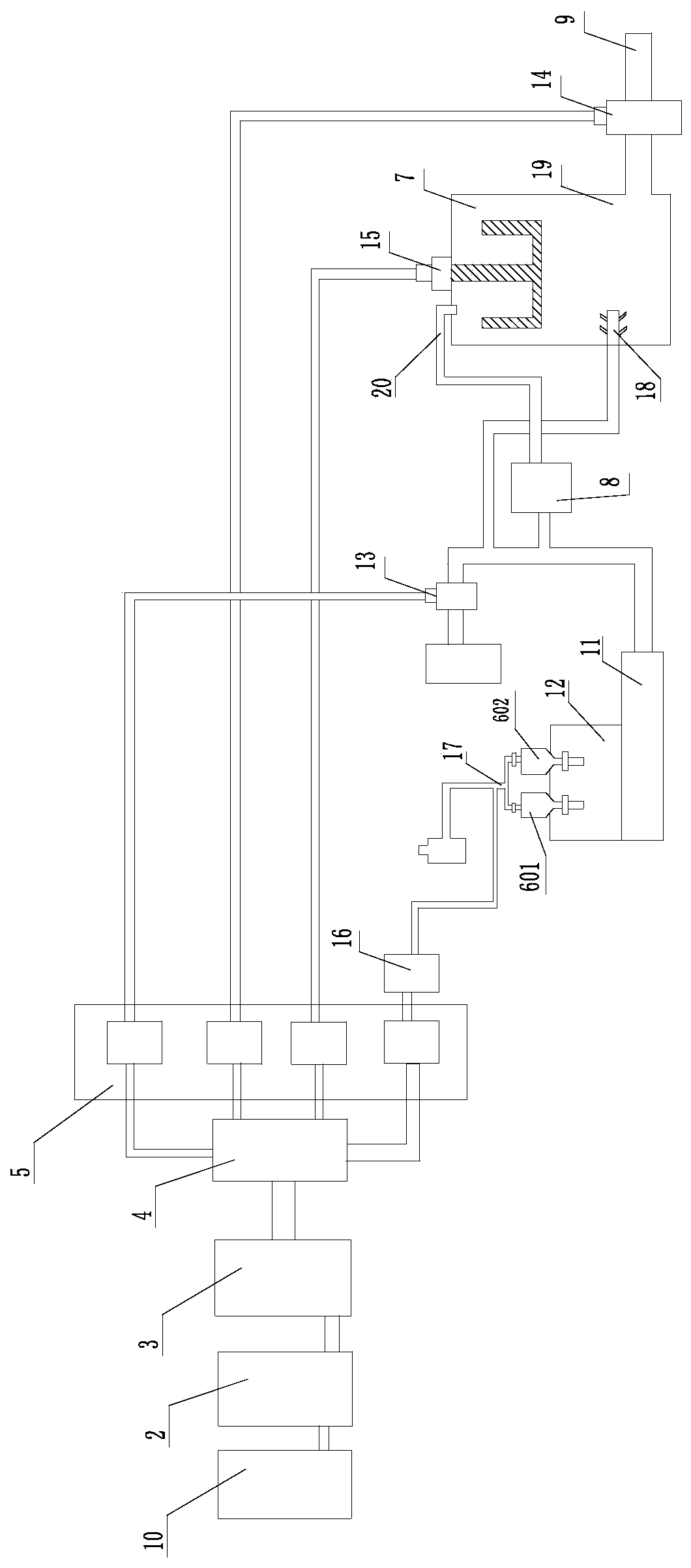

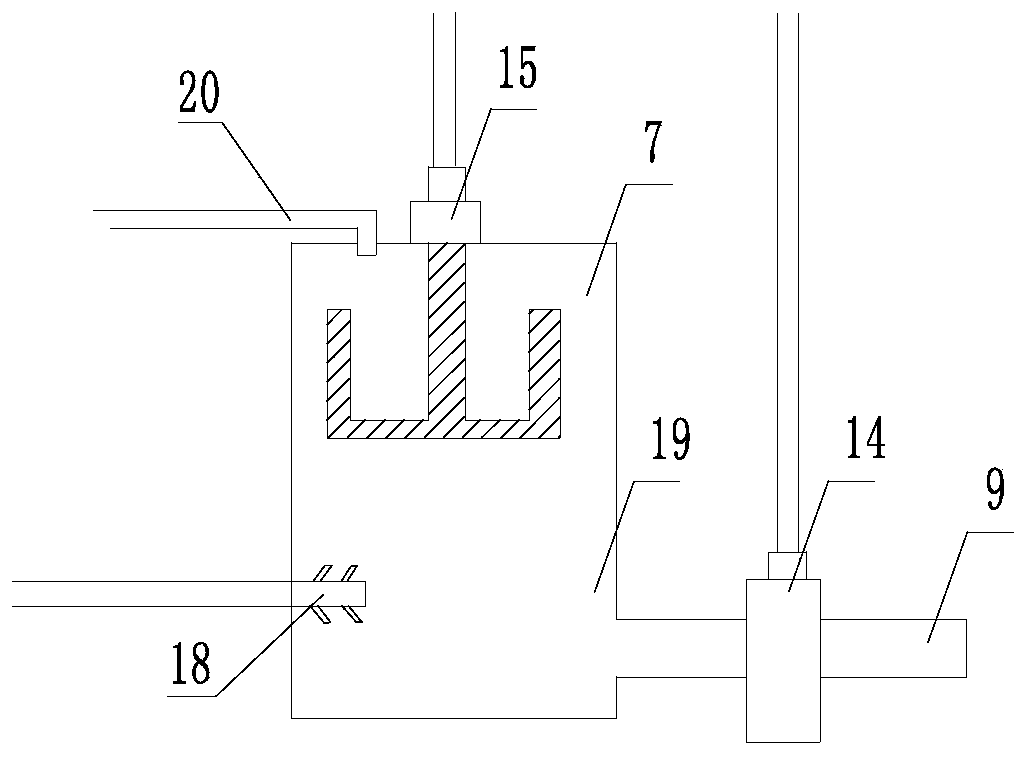

[0012] The present invention will be further described below in conjunction with accompanying drawing:

[0013] Depend on Figure 1 to Figure 3 As shown, a fracturing fluid mixing device includes a skid-mounted base on which a motor 2, a hydraulic oil tank 3, a material storage tank 12, a fuel oil tank 10, a powder material tank, and a fuel oil tank 10 are respectively fixed to provide fuel. The engine 2 provides power for the device, and the power is transmitted to the hydraulic pump 5 through the transfer case 4. There are four hydraulic pumps in the whole device, and the hydraulic pump 5 drives the water inlet centrifugal pump 13, the liquid outlet centrifugal pump 14, and the thickening pump respectively. The centrifugal pump 15 and the feeding pump 16 finally transmit the mechanical energy of the engine to each pump through the hydraulic system.

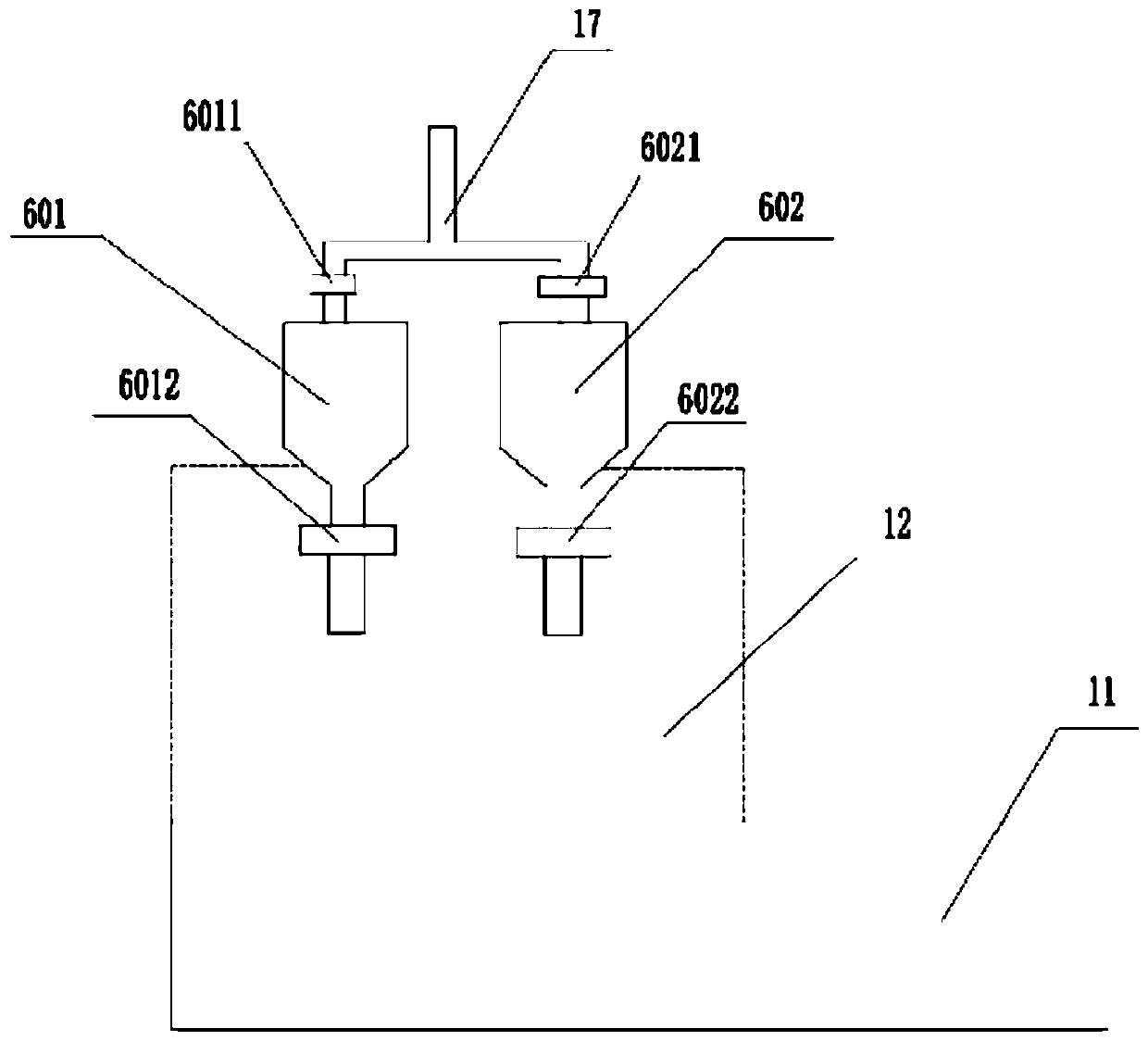

[0014] Described powder tank comprises powder tank A601 and powder tank B602, and the inlet of described powder tank A601 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com