Novel mixing pipe for sludge purifying equipment

A technology of purification equipment and mixing pipe, applied in the direction of dewatering/drying/concentrating sludge treatment, etc., can solve the problems of unsatisfactory mixing effect, large area of sludge conditioning tank and large investment, and achieve better mixing effect and speed. Fast, good mixing results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

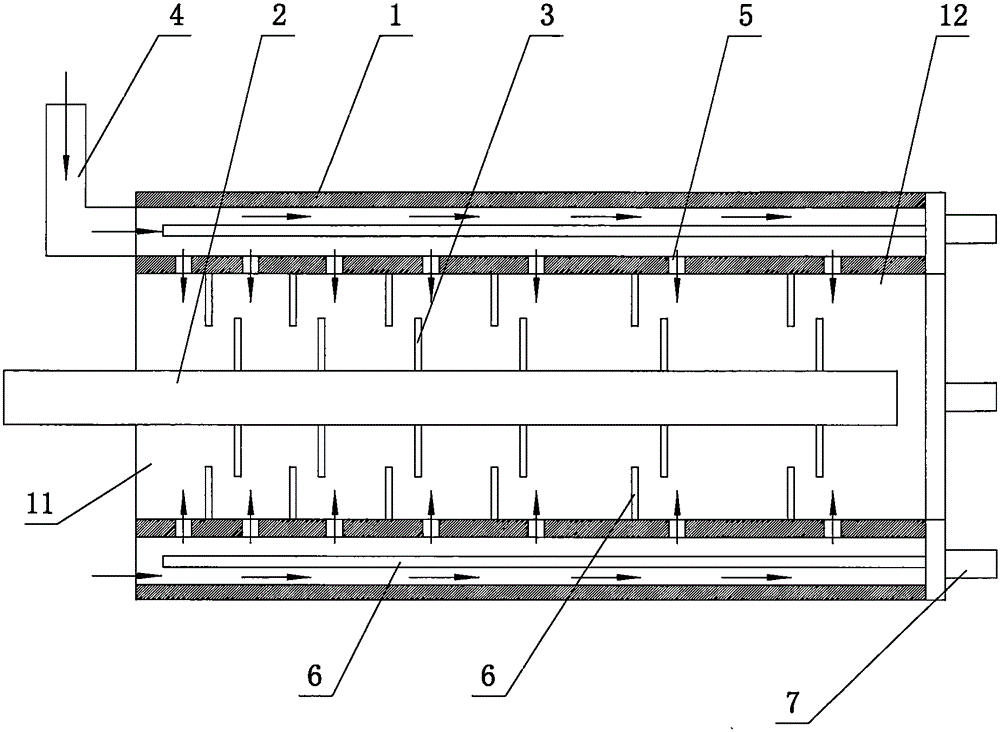

[0011] Such as figure 1 As shown, the new mixing tube of the sludge purification equipment of this embodiment includes a fixedly installed pipe sleeve 1 and a stirring shaft 2 movably installed in the pipe sleeve 1. The stirring shaft 2 has inner blades 3, and the pipe sleeve 1 The outer blade 8 is installed on the inner wall, and the inner blade 3 and the outer blade 8 are arranged at a staggered interval; the pipe wall of the pipe sleeve 1 has a hollow structure, and a flocculant introduction pipe 4 is installed on one end of the pipe wall, and the inner wall of the pipe sleeve 1 There are through holes 5 communicating with the inner cavity of the pipe wall at intervals, and the distance between adjacent through holes 5 gradually increases from the feed end 11 of the pipe sleeve 1 to the discharge end 12; the pipe wall of the pipe sleeve 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com