Sludge mixing device for manufacturing ceramsite

A technology of mixing device and sludge, which is applied in mixers, mixers with rotary mixing devices, sludge treatment and other directions, can solve the problems of inability to realize continuous mixing of sludge and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

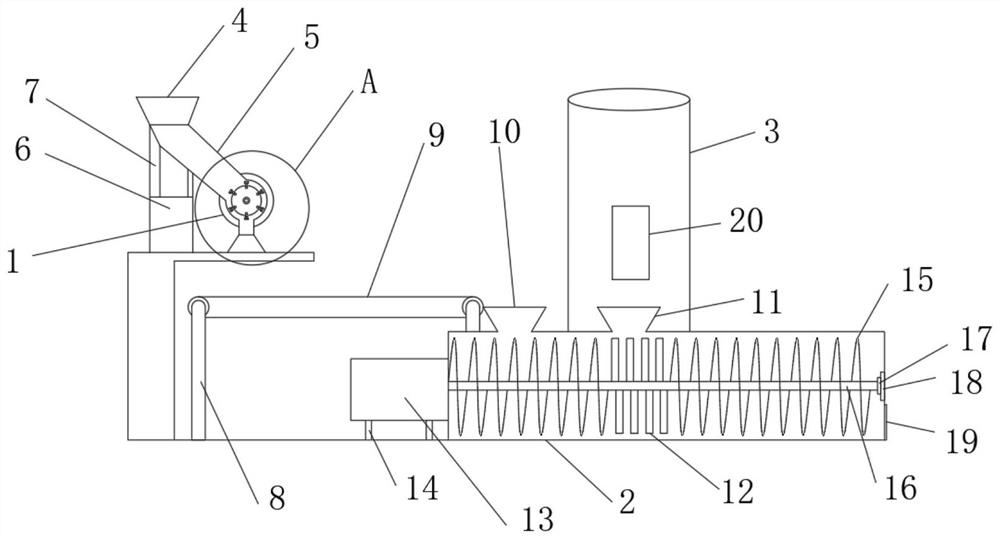

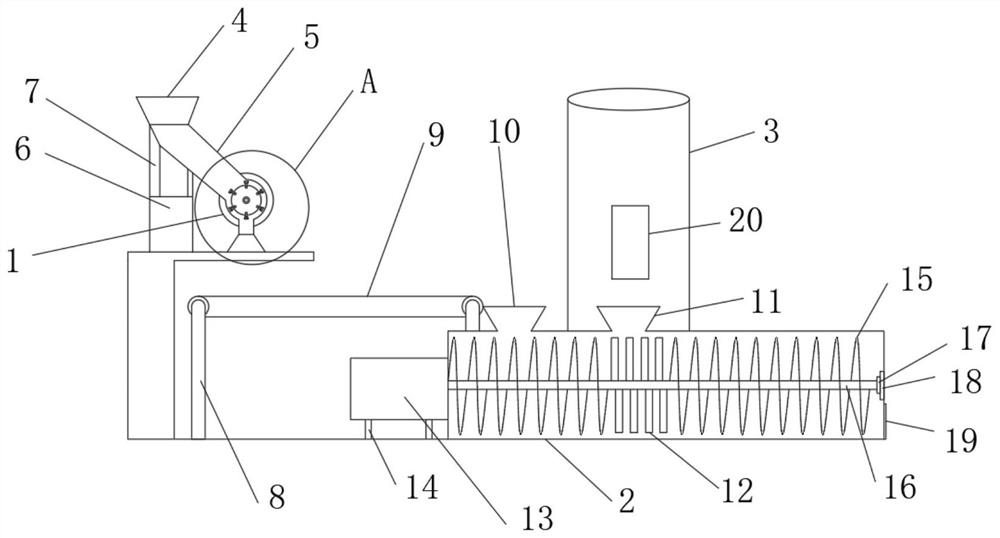

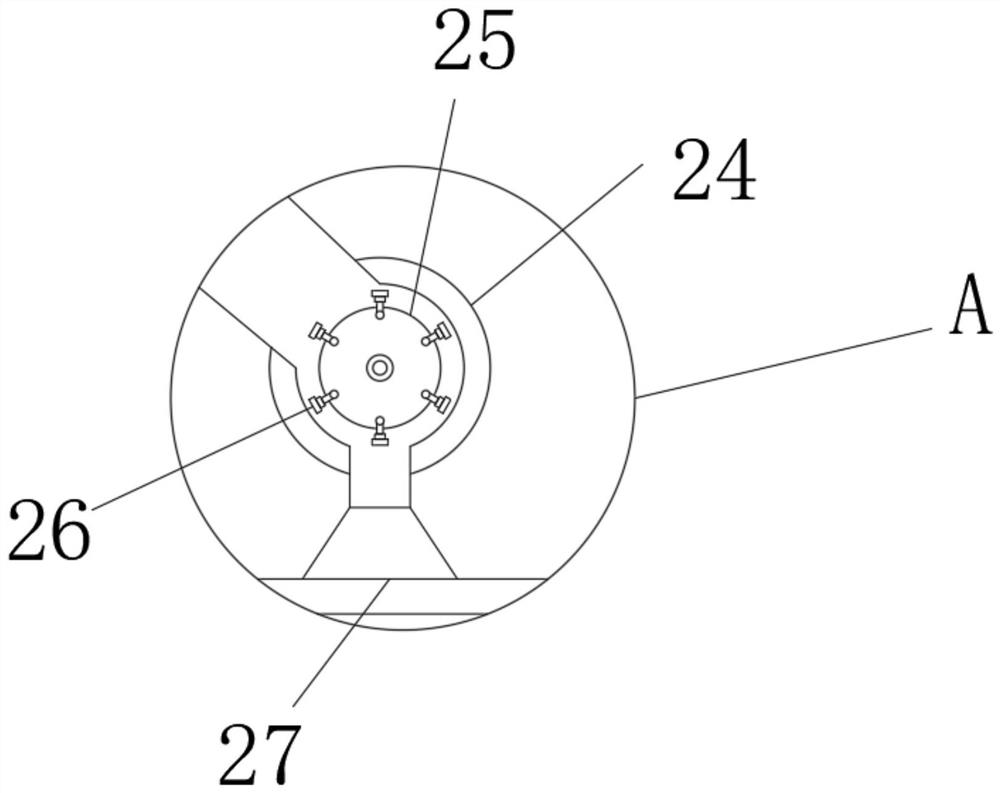

[0020] A sludge mixing device for producing ceramsite. In order to solve the problem that the existing sludge mixing device cannot fully mix dry sludge and wet sludge, dry sludge and wet sludge will appear at the discharge port. The problem of the situation where the sludge appears one after another, as a preferred embodiment, such as figure 1 , figure 2 As shown in Figure 3, it includes a pulverizer 1 and a mixing chamber 2. A dried sludge delivery pipe 5 is arranged on one side of the pulverizer 1, and a pulverizer feed port 4 is installed on the top of the dried sludge delivery pipe 5. The pulverizer 1 is provided with a dried sludge discharge port 23, the bottom of the dried sludge discharge port 23 is provided with a dried sludge conveyor belt 9, and the dried sludge conveyor belt 9 is fixed by a fixed rod 8, and the dried sludge A mixing chamber 2 is installed on the right side of the sludge conveyor belt 9, a dry sludge feed port 10 is provided on the top side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com