One-way water inlet film ice bag capable of achieving continuous filling and filling equipment

A technology for one-way water inlet and filling equipment, which is applied in the direction of lighting and heating equipment, bags, sacks, etc., can solve the problems of inability to achieve continuous filling and low efficiency, reduce filling costs, speed up filling, The effect of continuous filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

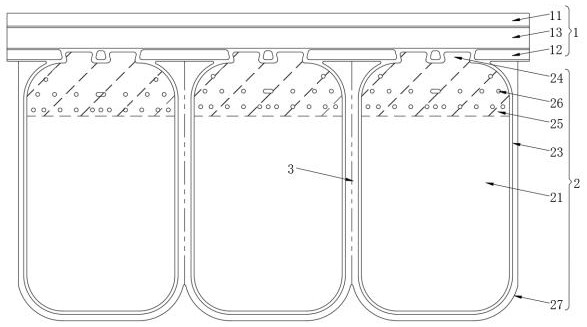

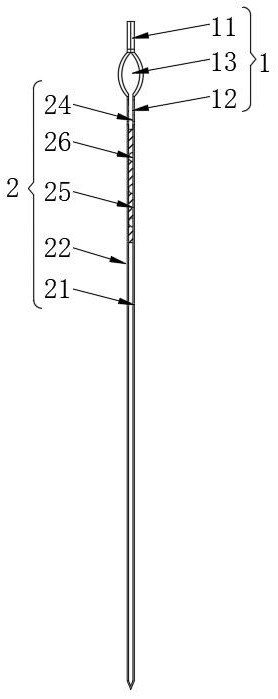

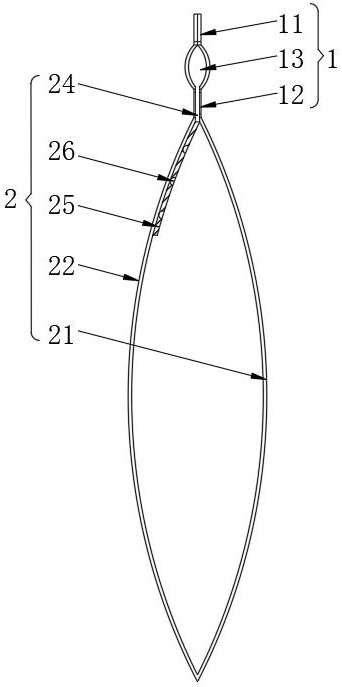

[0032] see Figure 1-3 , The present invention provides a technical solution: a continuous filling one-way water inlet film ice pack, comprising a plurality of ice pack assemblies 2 connected in one, the continuous filling joint 1 and the ice pack assembly 2 are both transparent plastic components. The continuous filling connection part 1 and the ice pack assembly 2 are integrated as a whole, which is made by the mold hot pressing process. The inlets of several ice bag assemblies 2 are connected with the continuous filling connection part 1. In order to facilitate the subsequent cutting work, phase A cutting part 3 is arranged between two adjacent ice pack assemblies 2, and the cutting part 3 is a linear structure.

[0033] Wherein, the continuous filling joint 1 includes a channel upper edge 11 and a channel lower edge 12 connected to several ice pack assemblies 2, and the channel upper edge 11 and the channel lower edge 12 together form a filling for water injection. Channe...

Embodiment 2

[0037] see Figure 5, the present invention provides a technical solution: a filling equipment, including a frame 4, the inner bottom end of the frame 4 is respectively installed with a water tank 5 and a water pump 6, the water outlet of the water tank 5 and the water inlet of the water pump 6 pass through the pipeline In series connection, an ice pack conveyor belt 7 and a protective box 8 are respectively installed on the upper part of the frame 4, and a continuous filling unit 9 is installed at the front end of the protective box 8. The continuous filling unit 9 is located above the conveying edge of the ice pack conveyor belt 7. The protective box The rear end of 8 is installed with a receiving motor 10, and the driving end of the receiving motor 10 is installed with a waste discharge wheel 14 (two waste discharge wheels 14 are provided, one of which is connected in series with the driving end of the receiving motor 10, and the other rotates. Installed on the protective b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com