Continuous backfilling gangue projection system

A technology for gangue and connecting components, applied in the field of coal mining equipment, can solve problems such as low filling rate, and achieve the effects of improving filling rate, continuous filling, and improving filling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

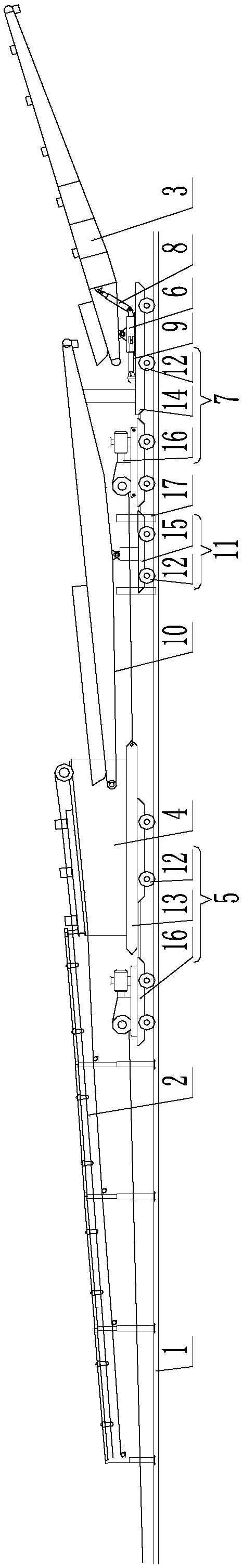

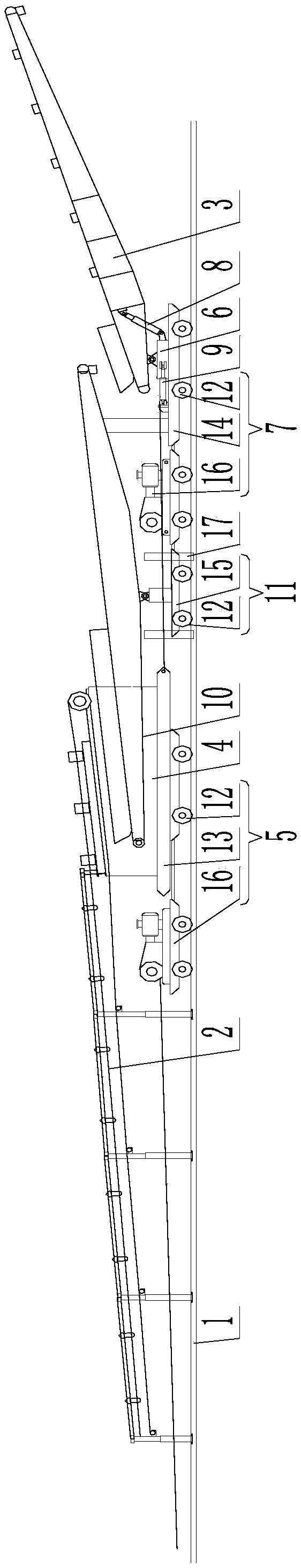

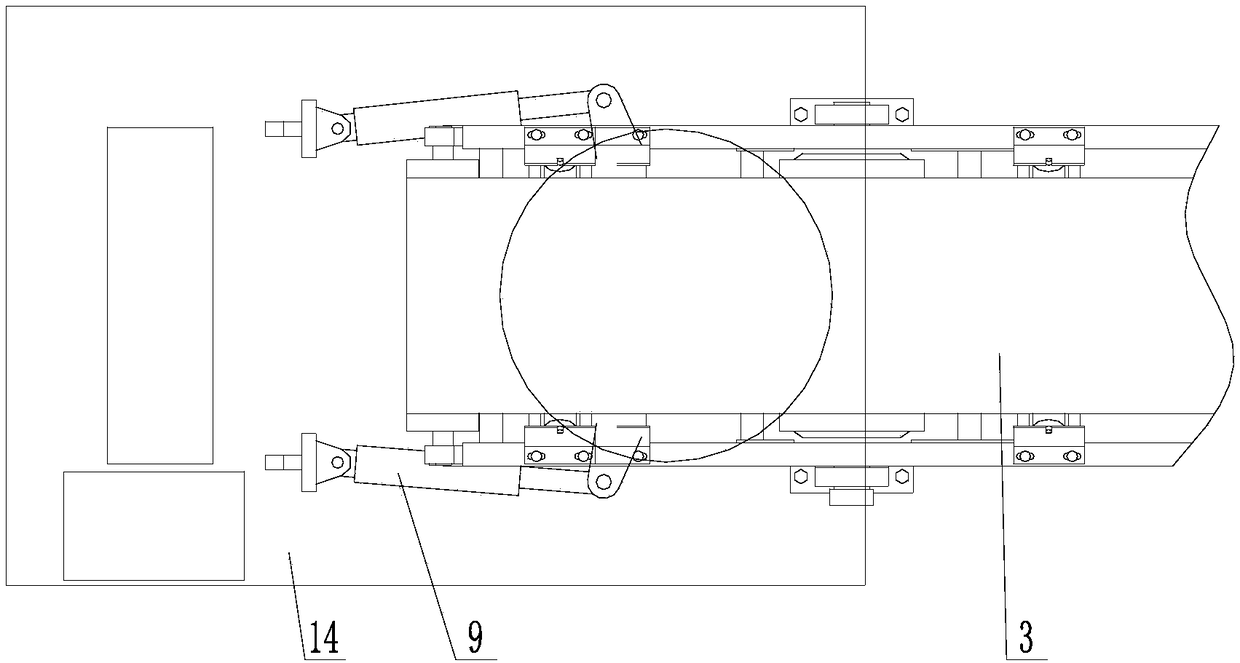

[0019] A gangue projecting system for continuous filling, which is set on the track 1 in the roadway. The projecting system includes a feeding belt conveyor 2 and a projecting belt conveyor 3 connected to the discharge end of the feeding belt conveyor 2. The key is that the The tail of the feeding belt conveyor 2 is provided with a mounting seat 4, the mounting seat 4 is connected with the first traveling mechanism 5, the described mounting seat 4 is an open hollow cylinder, and the projecting belt conveyor 3 is rotated The workbench 6 is arranged on the second traveling mechanism 7, the feeding end of the projecting belt conveyor 3 is hinged to the rotary table 6, and the first telescopic unit 8 is hinged between the projecting belt conveyor 3 and the rotary table 6, Second telescopic units 9 are respectively hinged between both sides of the rotary table 6 and the second traveling mechanism 7 .

[0020] Specific examples, such as Figure 1-3 As shown, the feeding belt convey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com