Pre-weighed reciprocating fluid weight output filling device

A filling device, reciprocating technology, applied in the field of pre-weighing reciprocating fluid weight output filling device, can solve the problems of container overfilling, time-consuming and laborious, excessive fluid filling, etc., and achieve the effect of reasonable device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

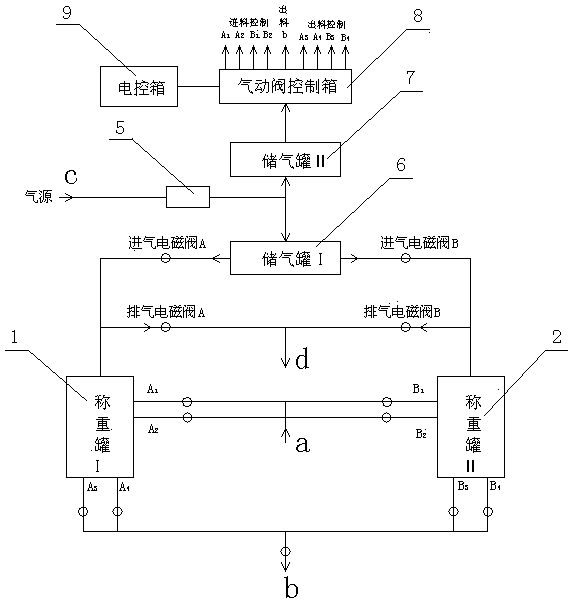

[0014] The pre-weighing reciprocating fluid weight output filling device of the present invention, such as figure 1 As shown, it is composed of a weighing tank and an electric control box. The weighing tank I1 and the weighing tank II2 are arranged side by side, and the bottom of the weighing tank I1 and the weighing tank II2 are connected to the elastic fixing plate through the support angle 3 Phase I4 is fixed, and a weight sensor is provided at the bottom of the elastic fixing plate I4;

[0015] Large flow inlet pipe A connected to feed pipe a 1 and small flow inlet pipe A 2 Both are connected to the weighing tank I1 pipeline, and the large flow inlet pipe B connected to the feed pipe a 1 and small flow inlet pipe B 2 Both are connected to the weighing tank Ⅱ2 pipeline; the bottom of the weighing tank Ⅰ1 is connected to the large flow outlet pipe A 3 and small flow outlet pipe A 4 Connection; the bottom of the weighing tank Ⅱ2 and the large flow outlet pipe B 3 and sm...

Embodiment 2

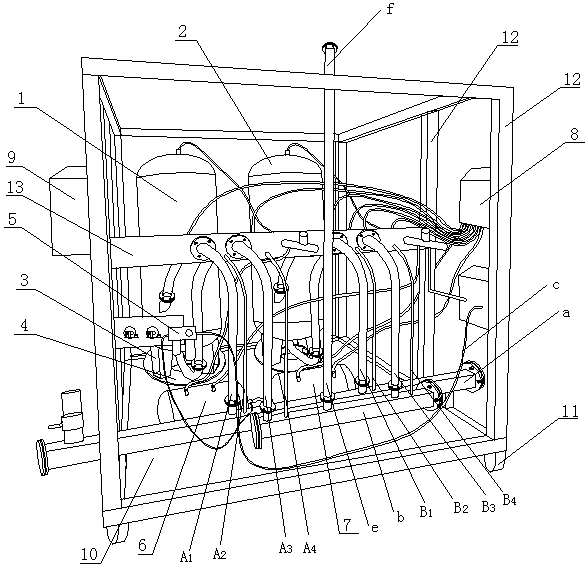

[0019] The pre-weighing reciprocating fluid weight output filling device of the present invention is composed of weighing tank I1, weighing tank II2, gas storage tank I6, gas storage tank II7, electric control box 9 and square mobile seat 10, as figure 2 shown.

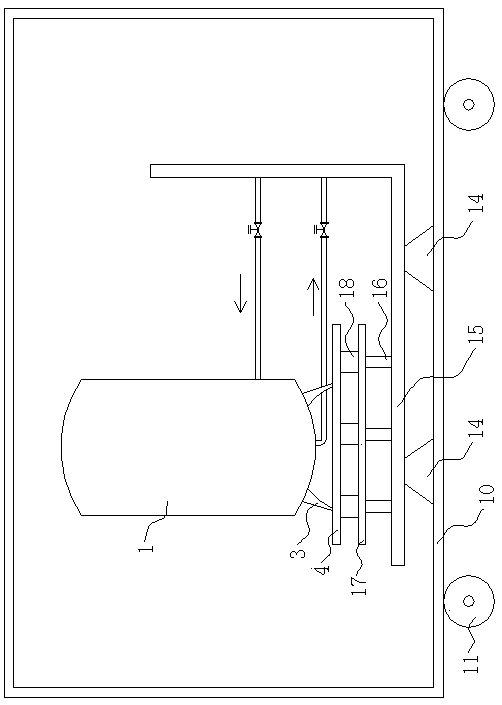

[0020] The weighing tank I1 and the weighing tank II2 are arranged side by side on the moving seat 10, and the bottoms of the weighing tank I1 and the weighing tank II2 are fixed to the elastic fixing plate I4 through the supporting angle 3; There is an elastic fulcrum 14, and a stable frame 15 is arranged on the elastic fulcrum 14, and three fixed fulcrums 16 are evenly distributed on the horizontal frame of the stable frame 15, and the fixed fulcrum 16 has an elastic fixed plate II17, and the elastic fixed plate I4 and the elastic fixed plate Three weight sensors 18 are fixed between II 17, and the weight sensors 18 are connected with the electric control box 9 circuits, such as image 3 shown. On the vertical fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com