Multi stope fast switching continuous filling device and its application method

A technology of fast switching and filling device, applied in the direction of filling, safety device, mining equipment, etc., can solve the problem of low filling efficiency, and achieve the effect of improving filling efficiency, high practicability and high integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

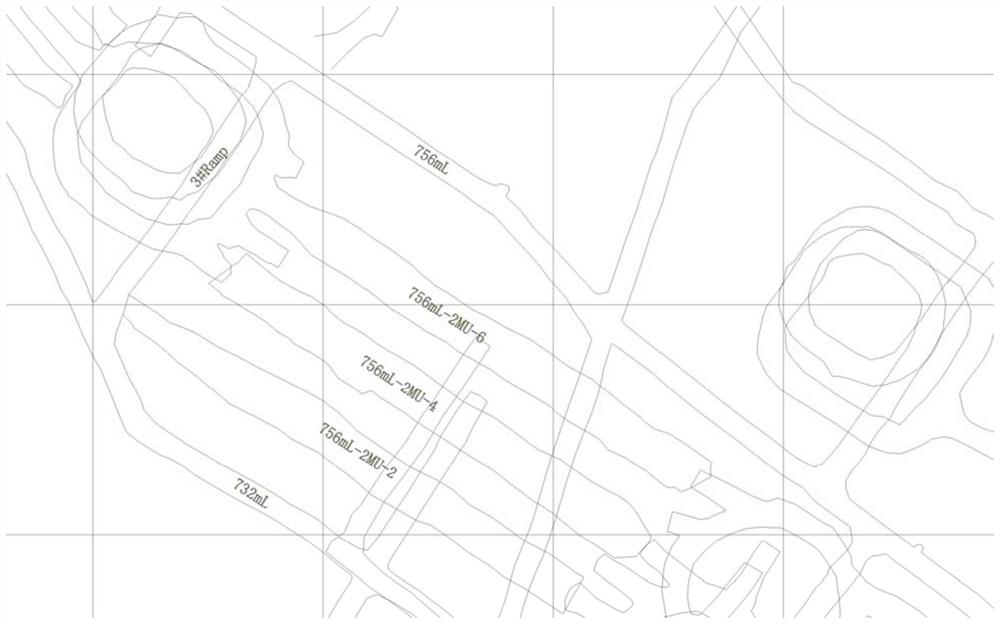

[0035] A copper mine invested by our country in Zambia has a designed annual output of 3 million tons. It adopts two-step subsequent paste filling with a filling capacity of 160m 3 / h. Such as figure 2 As shown, the three stopes of the mine 756-2MU-2 / 4 / 6 are now described for the application of the embodiment. The three stopes are 93-106m long, 8m wide, 13-14m high, and the stope volume is 10381m 3 ~11837m 3 , because the mine uses a low-cost, reusable flexible filling retaining wall with a height of 4-5m. In order to ensure the safety of the retaining wall, it needs to be filled twice to pass through the retaining wall. In order to improve the filling efficiency, continuous filling of the three stopes must be realized.

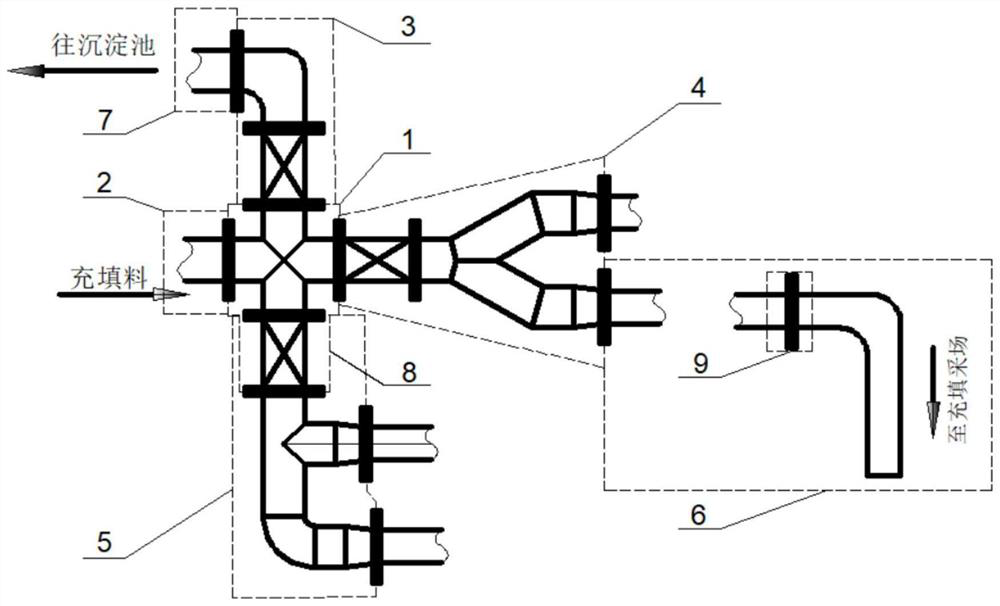

[0036] The continuous filling device used in this mine is briefly described as follows: the entrance of the four-way pipe 1 is connected to the filling rubber pipe 2 with an inner diameter of 175mm and a pressure resistance of 2.5MPa; the three outlets ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com