Mortar making system and process suitable for large horizontal sand silo of mine filling station

A technology for mine filling and sand silo, which is applied in filling materials, mining equipment, safety devices, etc., can solve the problems of complex construction process, unbalanced mining and filling of mines, affecting mine output, etc., and achieves the effect of reducing costs and protecting the environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

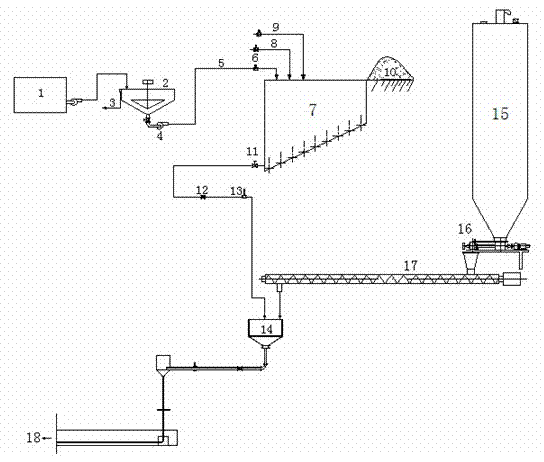

[0038] In order to further describe the present invention, a slurry making system and process suitable for large horizontal sand bins of mine filling stations will be described in detail below in conjunction with the accompanying drawings.

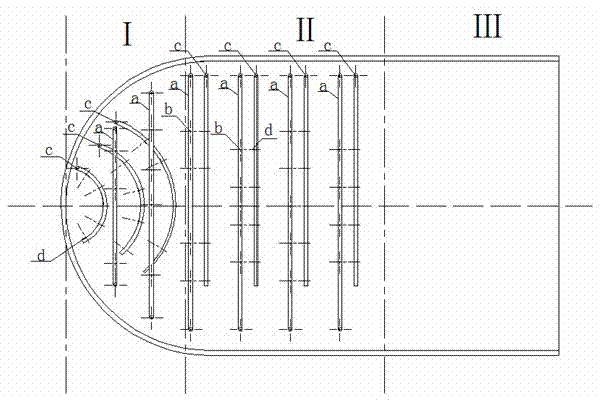

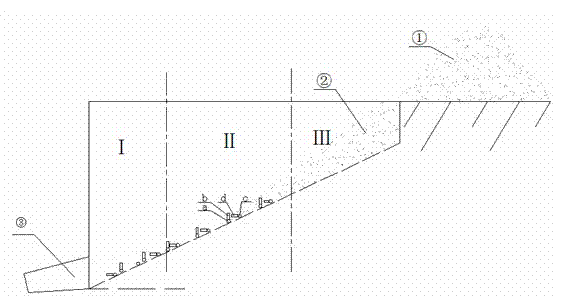

[0039] Depend on figure 1 The horizontal sand bin horizontal projection diagram that the present invention adopts shown combines figure 2 It can be seen that starting from the sand outlet, along the direction of the horizontal sand silo, it is divided into pulp making area Ⅰ, handling area Ⅱ, and sand storage area Ⅲ; the inclination angle of the bottom plate of the horizontal sand silo is 25o , the length of the slurry-making area I along the strike of the sand bin is 4m, the length of the transport area II along the strike of the sand bin is 7m, and the length of the sand storage area III along the strike of the sand bin is 6m.

[0040] Lay ring-shaped high-pressure water supply branch pipe c and high-pressure gas supply branch pipe a in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com