Dripping and spraying double-effect emitter and irrigation system thereof

A sprinkler and irrigation water technology, which is applied in the direction of spraying devices, watering devices, liquid spraying devices, etc., can solve the problems of affecting plant growth, easy blockage of water delivery devices, singleness, etc., and achieves multiple system functions and rational use of irrigation water resources, reducing the effect of water evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

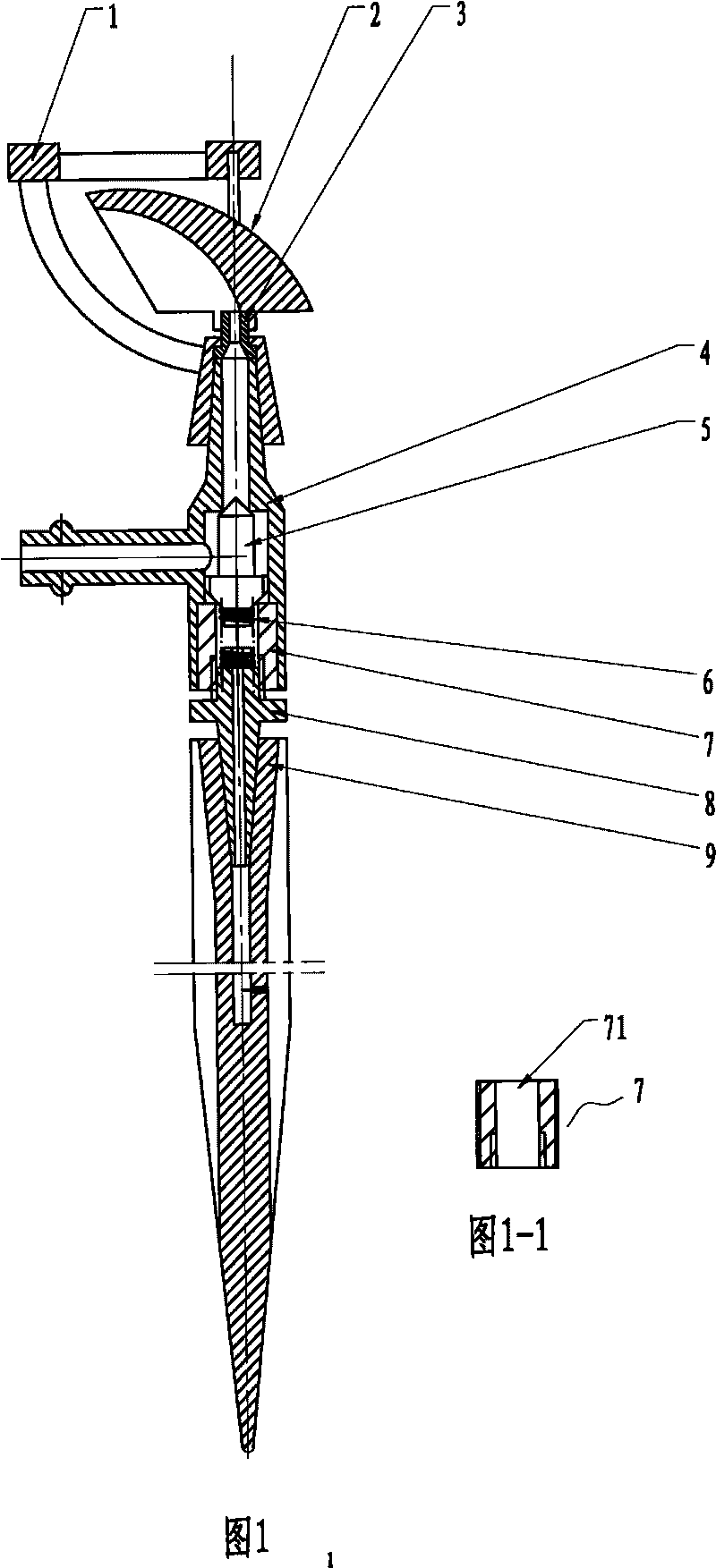

[0054] A drip spray double-effect irrigator, comprising a connecting body 4 with an irrigation water inlet, a nozzle part consisting of a support sleeve 3, a rotating body 2 and a rotating body bracket 1 located on the upper part of the connecting body 4, and a cone joint located on the lower part of the connecting body 4 8. The dripper part composed of the insertion rod 9 and the valve core 5 and spring 6 for changing the flow direction of the pressure water;

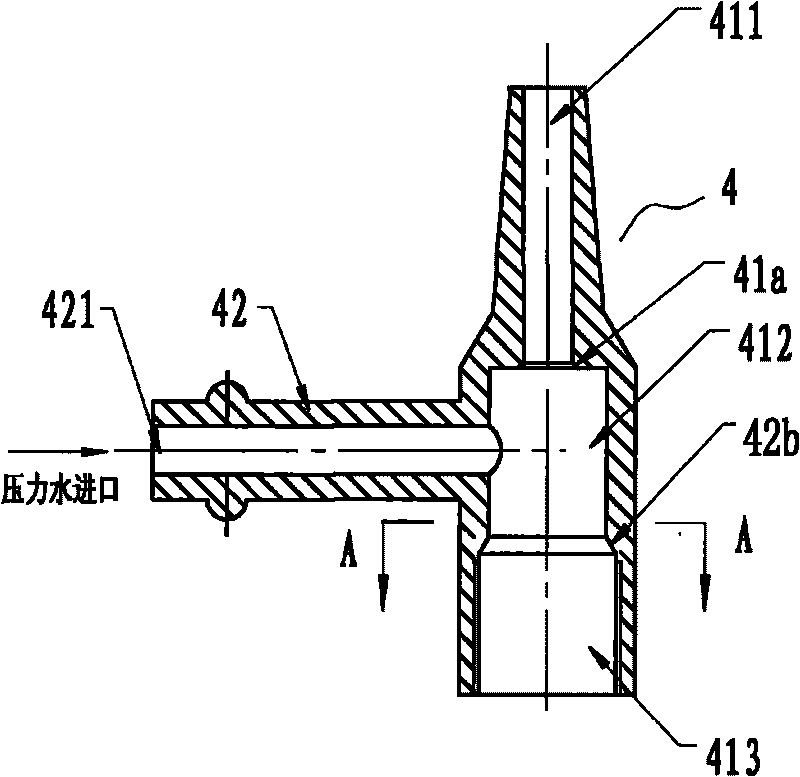

[0055]The shape of the connecting body 4 is a tubular part with a cylinder at one end and a cone at the other end. There are three stepped through holes in the center of the connecting body, the small hole section 411 of the connecting body stepped hole and the connecting body stepped hole. The junction of the hole section 412 is the transition of the conical surface 41a, and the large hole section 413 of the connecting body stepped hole has an internal thread, and its connection with the middle hole section 412 of the ...

Embodiment 2

[0078] A set of drip-spray double-effect irrigation system, including an agricultural agricultural system consisting of water pump IX, flow regulator VII, filter VI, water pipeline V, irrigation water pressure differential controller III, valve II and drip-spray double-effect irrigator I Irrigation system, its connections see Figure 10 , the drip-spray double-effect emitter 1 is the drip-spray double-effect emitter described in Embodiment 1 of the present invention, and this drip-spray double-effect emitter is designed by two kinds of pressure structures, so that sprinkling irrigation and drip irrigation can be carried out in one emitter Therefore, use this system to adjust the pressure of the water supply system through the pressure differential controller III to select drip irrigation or sprinkler irrigation, and realize the function of drip irrigation or sprinkler irrigation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com