Culture solution continuous filling method and system for chlamydomonas culture

A technology for culture solution and monocytogenes, which is applied to the field of continuous injection of culture solution for the cultivation of monocysts, can solve the problems of discontinuous process, stay, and stop growth, so as to avoid the entry of external bacterial impurities, facilitate operation, and prevent The effect of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

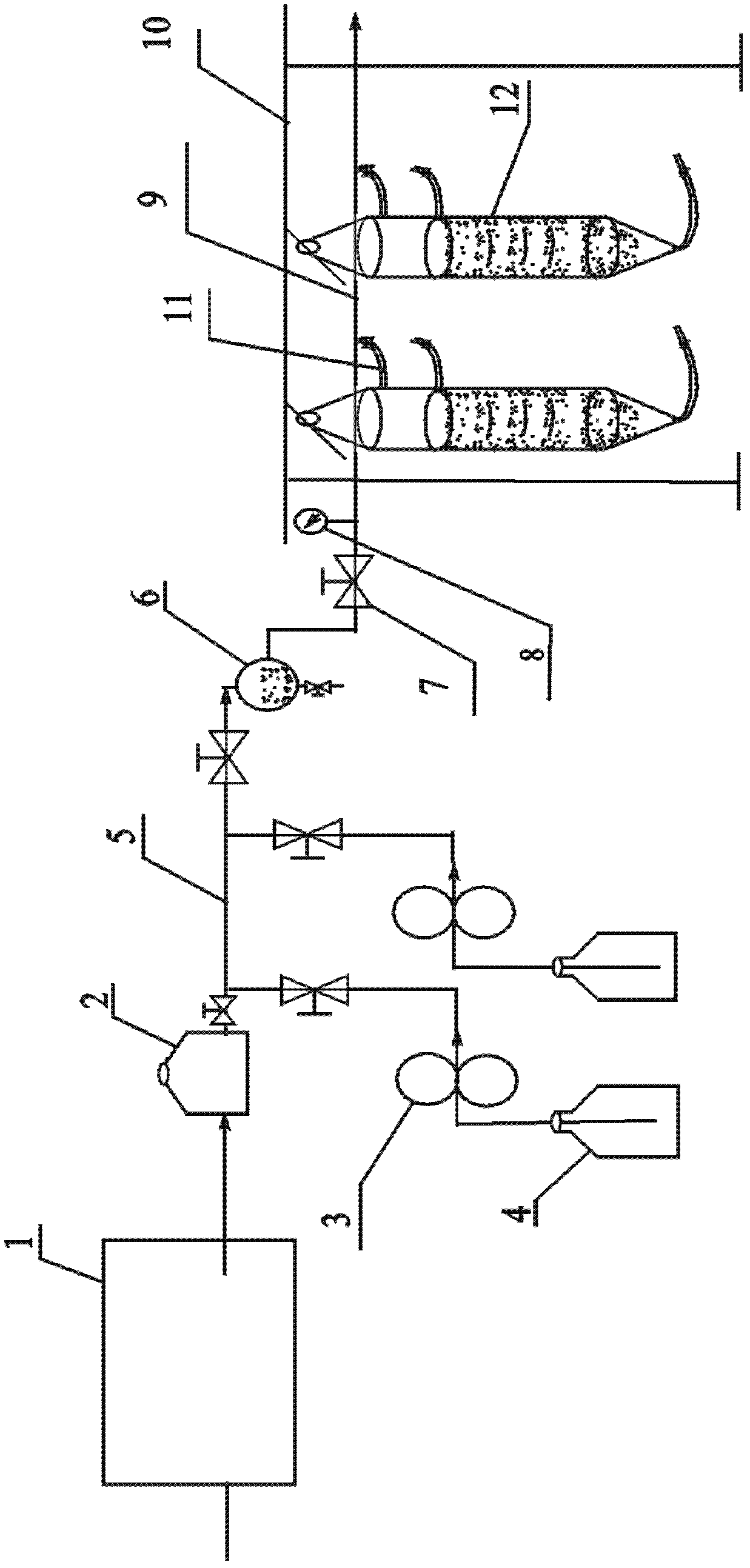

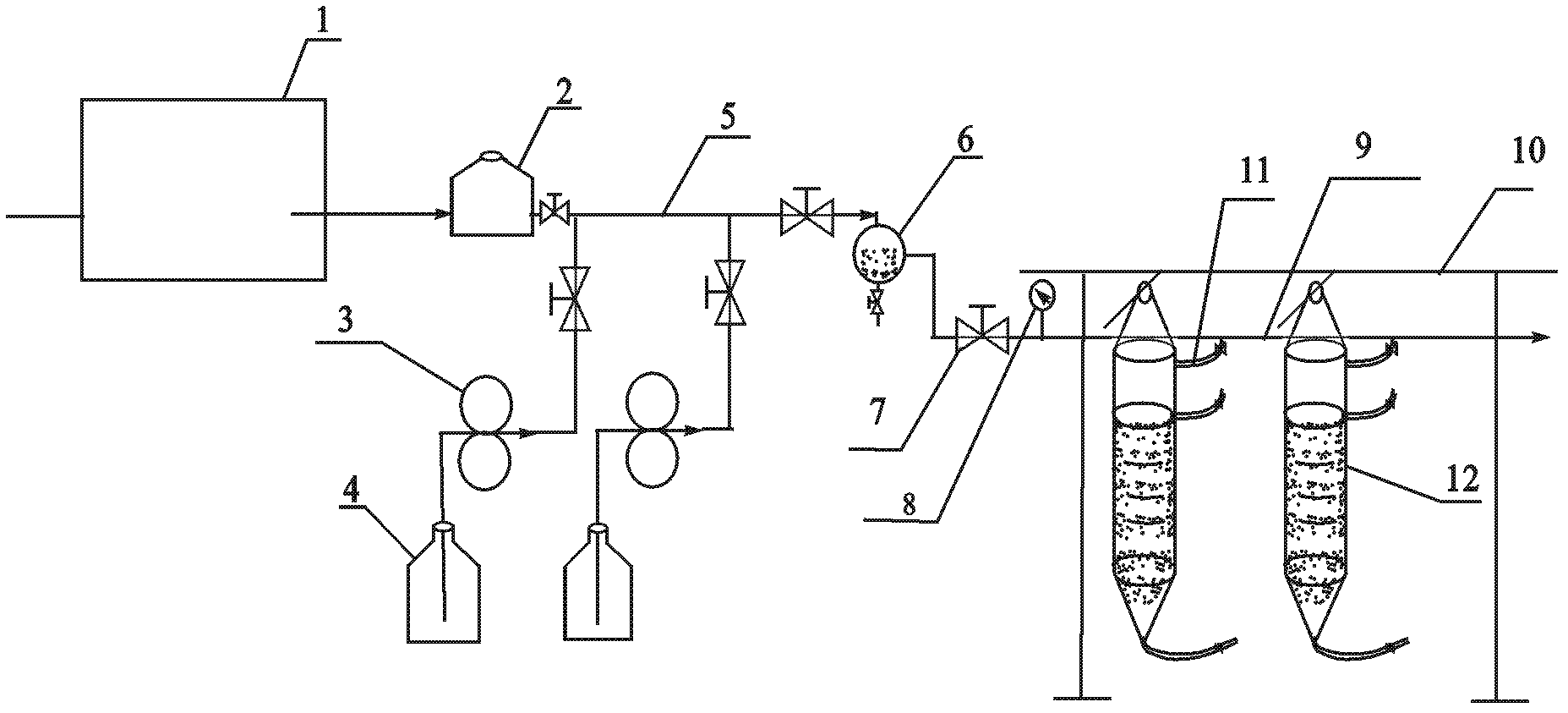

Method used

Image

Examples

Embodiment 1

[0043] First configure the nutrient solution as follows:

[0044] Nutrient solution C is as follows: Zinc chloride: 2g, cobalt chloride hexahydrate: 2.5g, ammonium dimethicate tetrahydrate: 1.2g, copper sulfate pentahydrate: 2g, hydrochloric acid: 10 mL, dissolved in 0.1 L deionized water; mother liquor.

[0045] Nutrient Solution A: Dissolve 2.8g ferric chloride hexahydrate, 0.5 g manganese chloride hexahydrate, 27.6g boric acid, 27g sodium EDTA dihydrate, 30g sodium dihydrogen phosphate dihydrate, 90g sodium nitrate, silicon Sodium acid: 20 g; and add the above nutrient solution C: 2 mL.

[0046] Nutrient Solution B: Vitamin B 12 : 0.3 g, Vitamin B 1 : 23 g, vitamin H: 0.13 g, dissolved in 1L deionized water as mother liquor.

[0047] Taking the 16L nutrient salt tank as an example, the nutrient solution A added with the nutrient solution C is added to the 16L nutrient salt tank according to the above ratio—that is, as the mother liquid, added to the 16L nutrient salt ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com