Automatically controlled hybrid phase change material melting and filling device

A technology of mixing phase change material and automatic feeding device, which is applied in liquid materials, packaging, transportation and packaging, etc., can solve the problem of low single filling efficiency, and achieve the effect of avoiding cooling and solidification blockage, reasonable structure and reliable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below with reference to the accompanying drawings and examples. The following examples are explanations of the present invention and are not limited to the following examples.

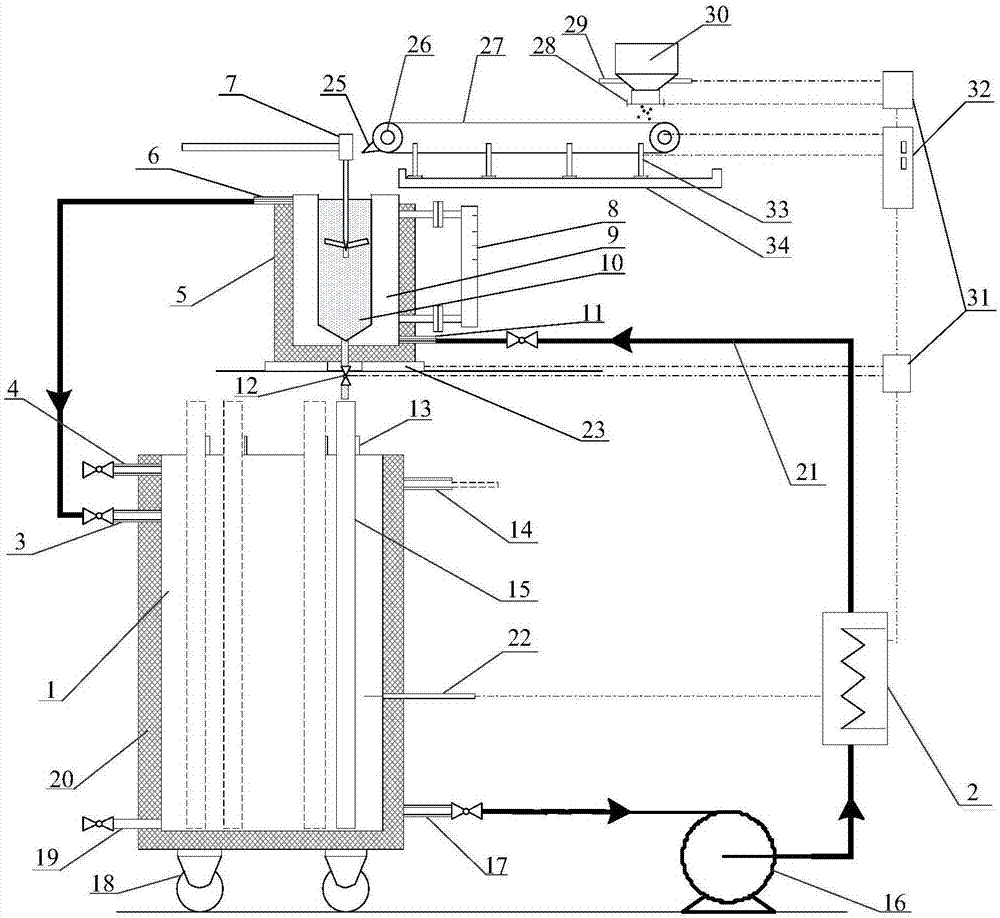

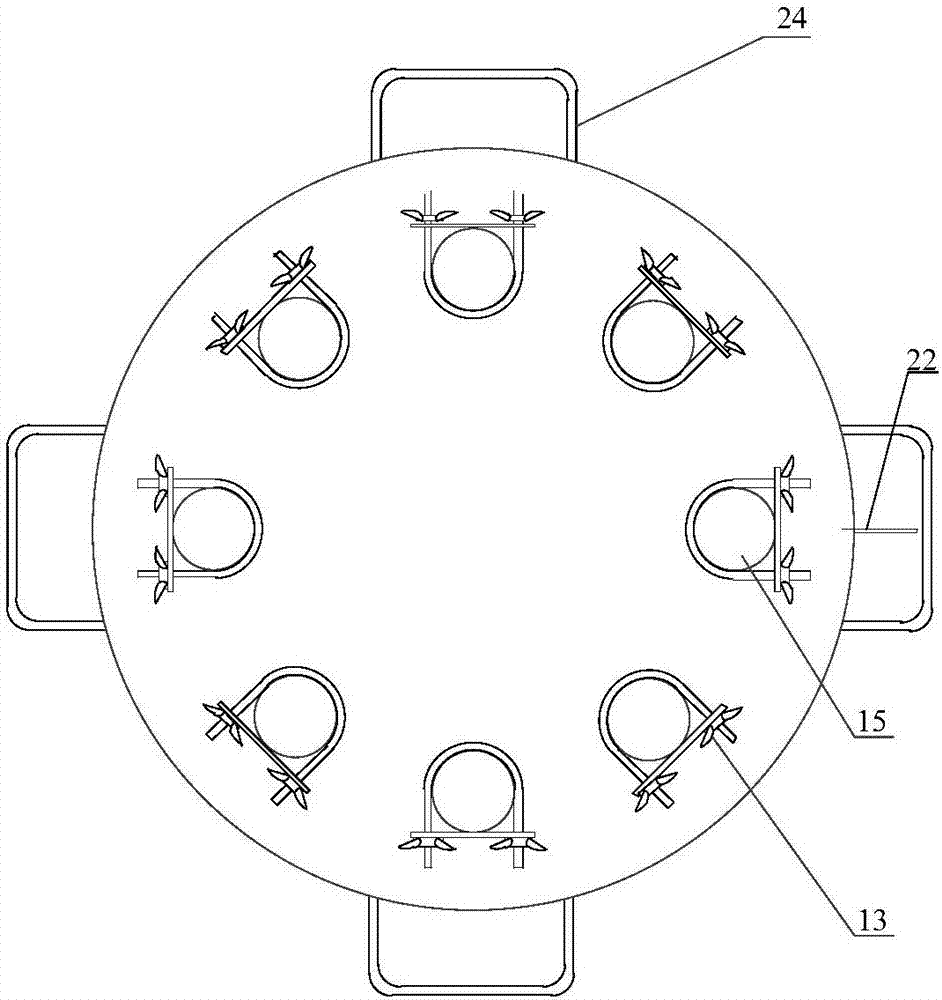

[0019] The embodiment of the present invention sees figure 1 and figure 2 , the mixed phase change material melting and filling device of this embodiment includes a temperature-controllable heating and constant temperature circulating medium box, an electric heater 2, a box heating medium inlet pipe 3, an overflow port 4, and a furnace body insulation layer 5 , Furnace heating medium outlet 6, lifting blade mixer 7, liquid level gauge 8, heating furnace outer cavity 9, furnace heating medium inlet 11, discharge valve 12, fixed plate clamp 13, heating medium compensation port 14 , circulating working medium pump 16, box heating working medium outlet pipe 17, universal wheel 18, sewage outlet 19, box body insulation layer 20, metal hose 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com