Filling machine for seasonings prepared from yellow serofluid of bean curd production line

A production line, yellow slurry water technology, applied in the safety device of filling device, packaging, bottle filling and other directions, can solve the problems of inconvenient filling, waste of resources, a large number of personnel, etc., to maintain stable, continuous filling, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

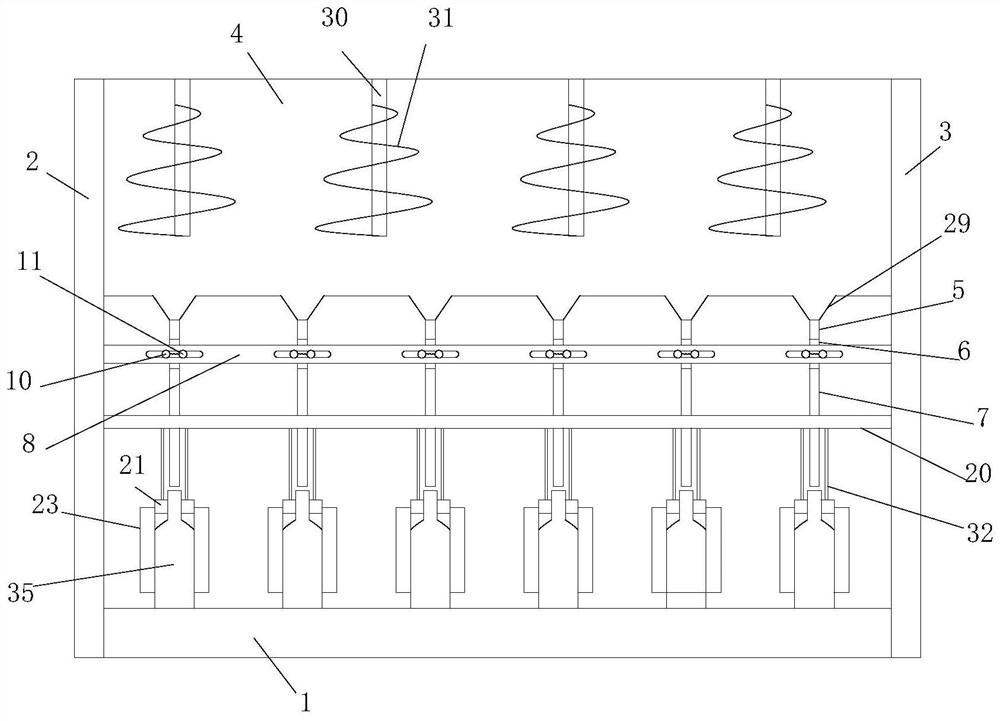

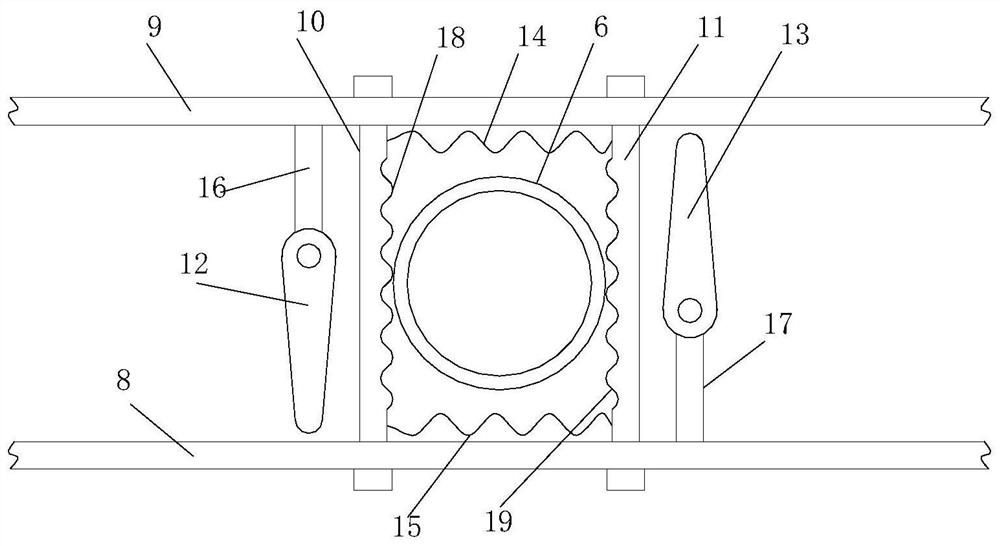

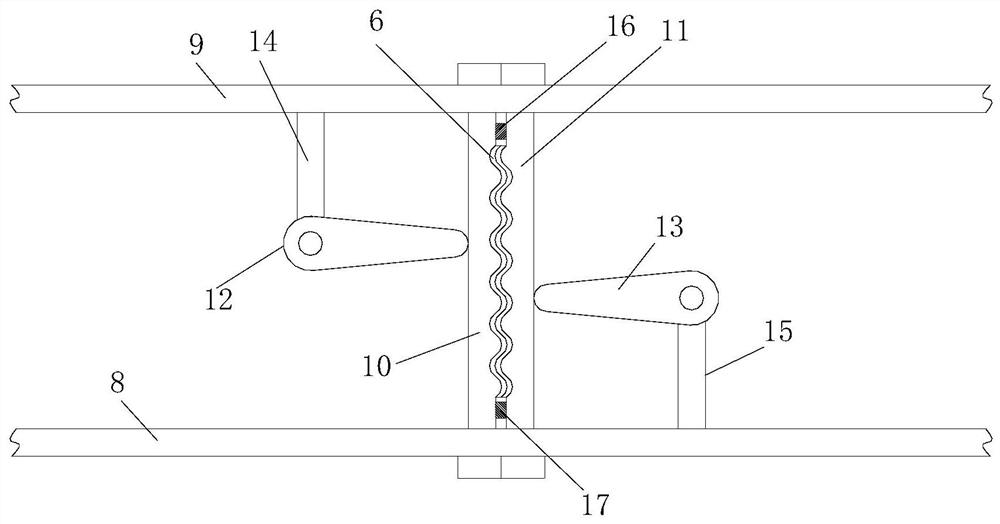

[0021] refer to Figure 1-Figure 4 , the present invention proposes a kind of seasoning filling machine that utilizes the yellow pulp water of tofu production line to prepare, comprising filling positioning platform 1, first transmission mechanism 33, second transmission mechanism 34 and filling mechanism; Wherein:

[0022] The filling positioning platform 1 is arranged horizontally and the filling positioning platform 1 is provided with a conveying surface, and a plurality of linearly distributed positioning pieces for positioning the filling bottle 35 are arranged on the conveying surface, and the two ends of the filling positioning platform 1 are respectively provided with The first stand 2 and the second stand 3 arranged vertically.

[0023] The first conveying mechanism 33 and the second conveying mechanism 34 are arranged on both sides of the filling positioning platform 1 respectively, the first conveying mechanism 33 is used to convey the filling bottle 35 to a plurali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com