Production equipment of paper pulp molding product and method for producing molding product by applying same

A pulp molding and production device technology, applied in textiles and papermaking, etc., can solve the problems of increasing the processing steps of molded products, increasing the manufacturing cost of equipment, etc., and achieves the effect of easy cleaning and maintenance, improving production efficiency and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

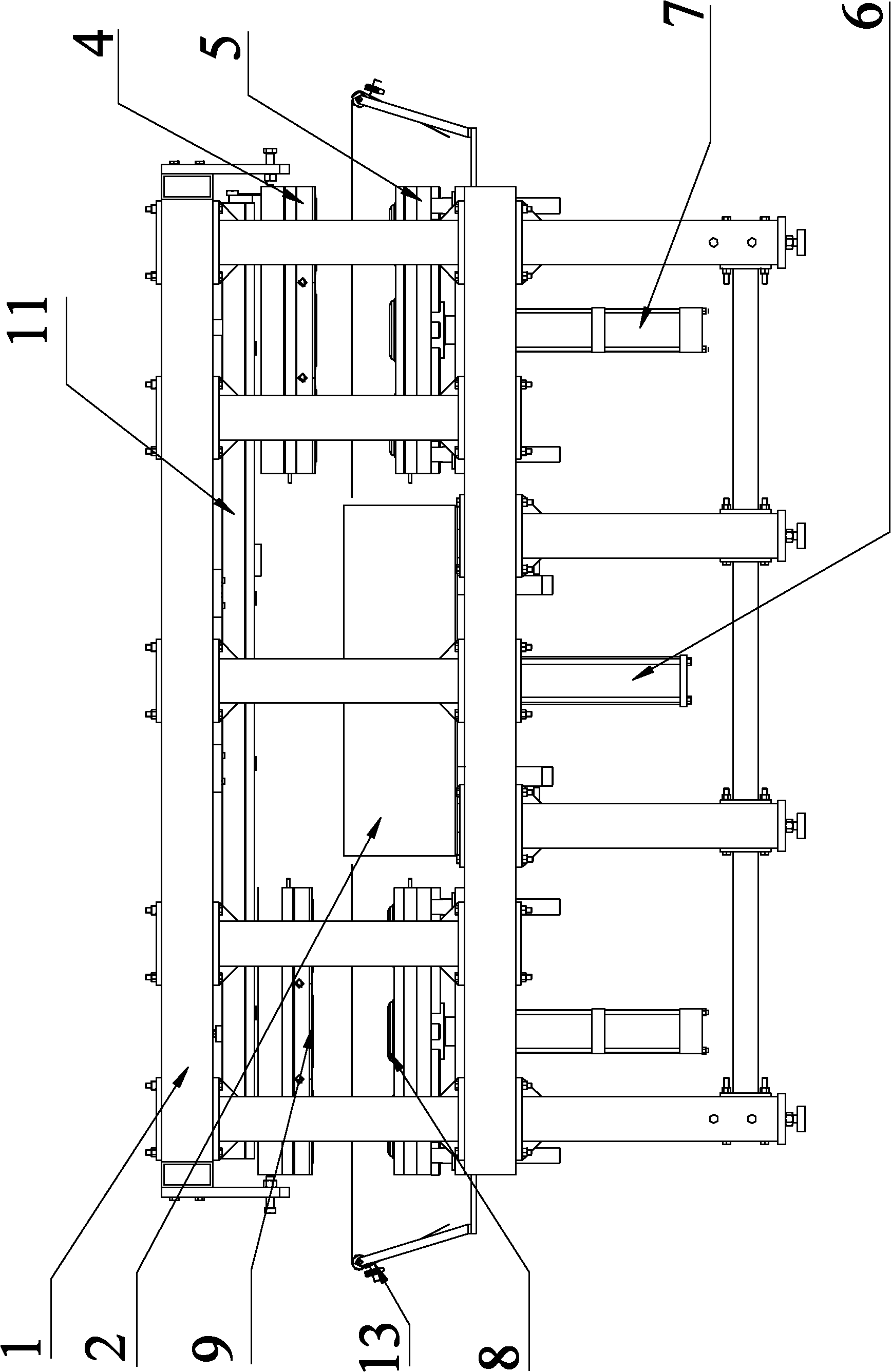

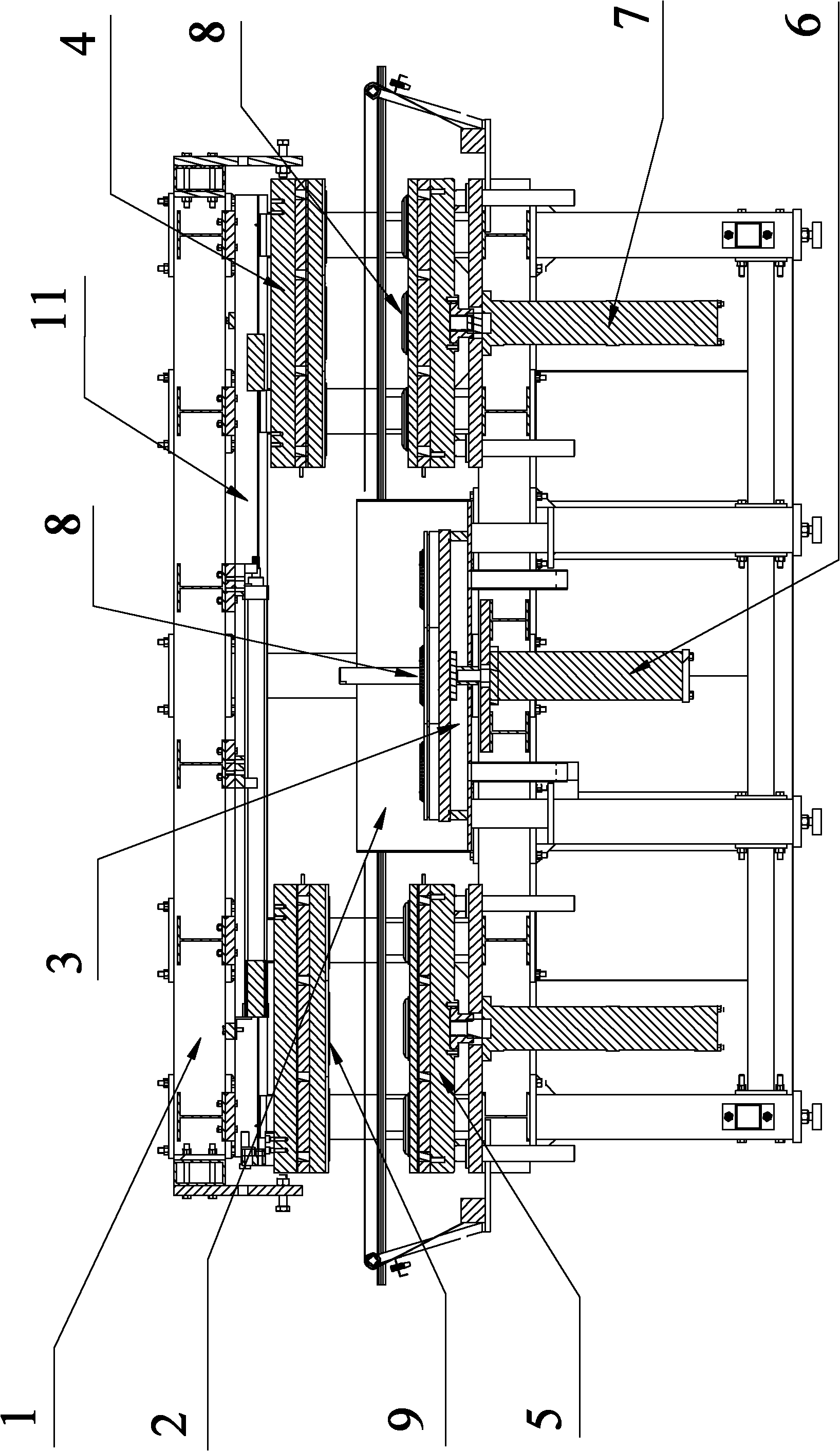

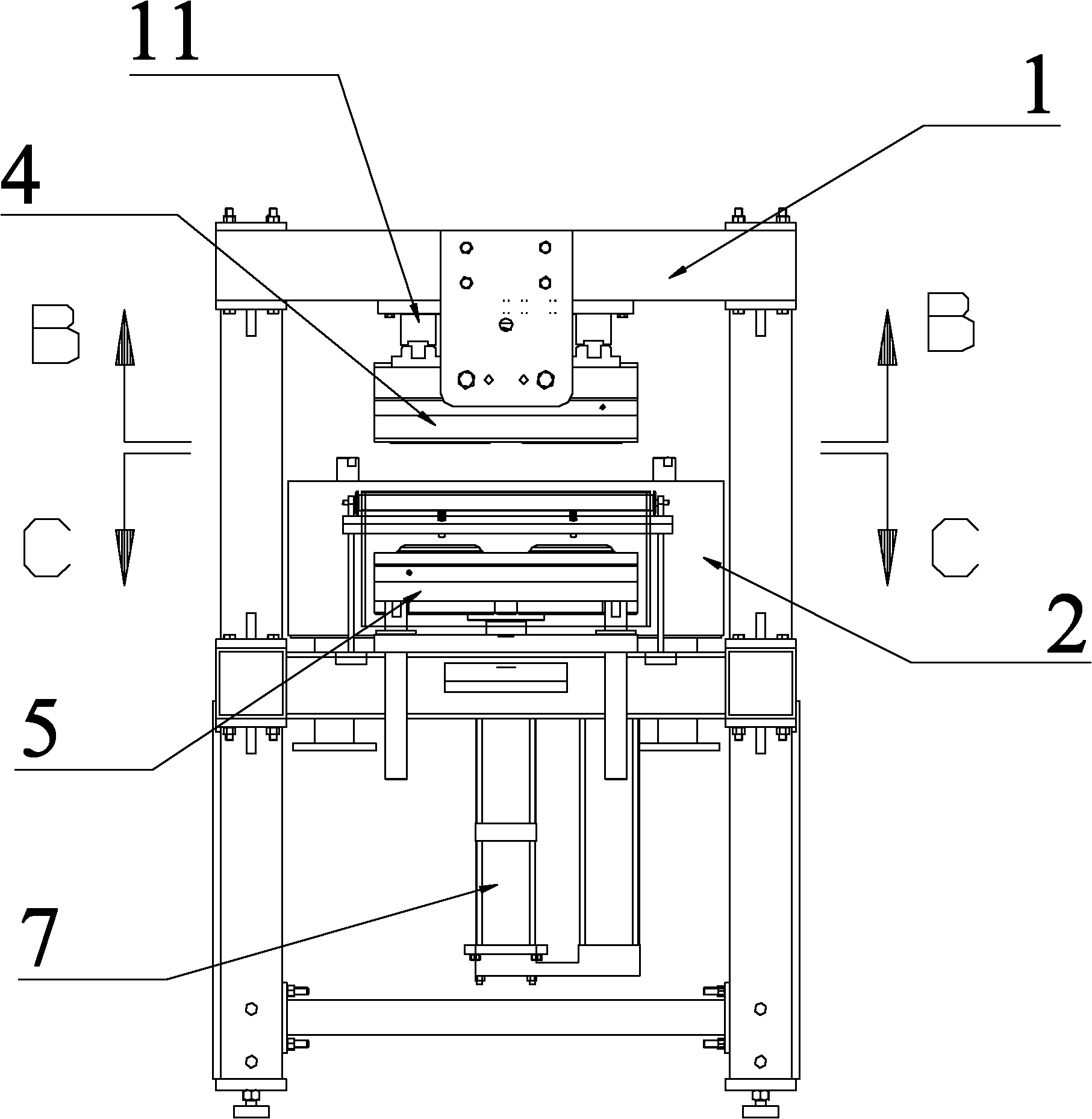

[0064] figure 1 Shown is the first preferred embodiment of the pulp molded product production device of the present invention, shown as the initial state of the device, which includes a frame 1, two die moving mechanisms 4 are arranged on the top of the frame 1, and the die moves The mechanism is connected to the sliding part and the driving device 12, and is connected to the slide rail on the frame through the sliding part. A slurry tank 2 is arranged in the middle part of the lower part of the frame, and a punch wet blank forming pre-pressing mechanism 3 is arranged in the slurry tank, the lower part of the punch wet blank forming prepress mechanism is connected to the cylinder 6, and the bottom of the slurry tank is provided with a grouting port and a vacuum suction port. The shaping drying mechanism 4 is equidistantly arranged on both sides of the slurry tank respectively, and the position of the shaping drying mechanism corresponds to the two concave mold moving mechanism...

Embodiment 2

[0067] This embodiment is the second preferred embodiment of the pulp molded product production device of the present invention. Its structure is basically the same as that of Embodiment 1, the only difference is that there are two pre-pressing mechanisms for the wet blank forming of the punch, and a shaping and drying mechanism. Set 3, the said die moving mechanism set 3, and the initial position corresponds to the shaping drying mechanism. On the outer sides of the two longitudinal ends of the frame, an automatic box-connecting device is installed near the position of the shaping drying mechanism, and an automatic box-connecting device is installed on the side of the frame of the qualitative drying mechanism near the middle of the frame.

Embodiment 3

[0069] This embodiment is the third preferred embodiment of the pulp molded product production device of the present invention. Its structure is basically the same as that of Embodiment 2, the only difference being that the punches on the punch wet body forming pre-pressing mechanism and the setting drying mechanism are respectively The number of dies on the die moving mechanism is 4, and the positions correspond to the punches on the wet billet forming pre-pressing mechanism and the shaping drying mechanism respectively.

[0070] The forming net arranged on the lower surface of the die is a galvanized net with a mesh number of 20 mesh and a steel wire diameter of 1mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com