Automatic tape splicing machine for lithium battery pole piece

A technology of splicing machine and lithium battery, which is applied in the direction of battery electrodes, circuits, electrical components, etc., and can solve the problems of uneven handling at the interface, contact pole pieces, dust and other sundries.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

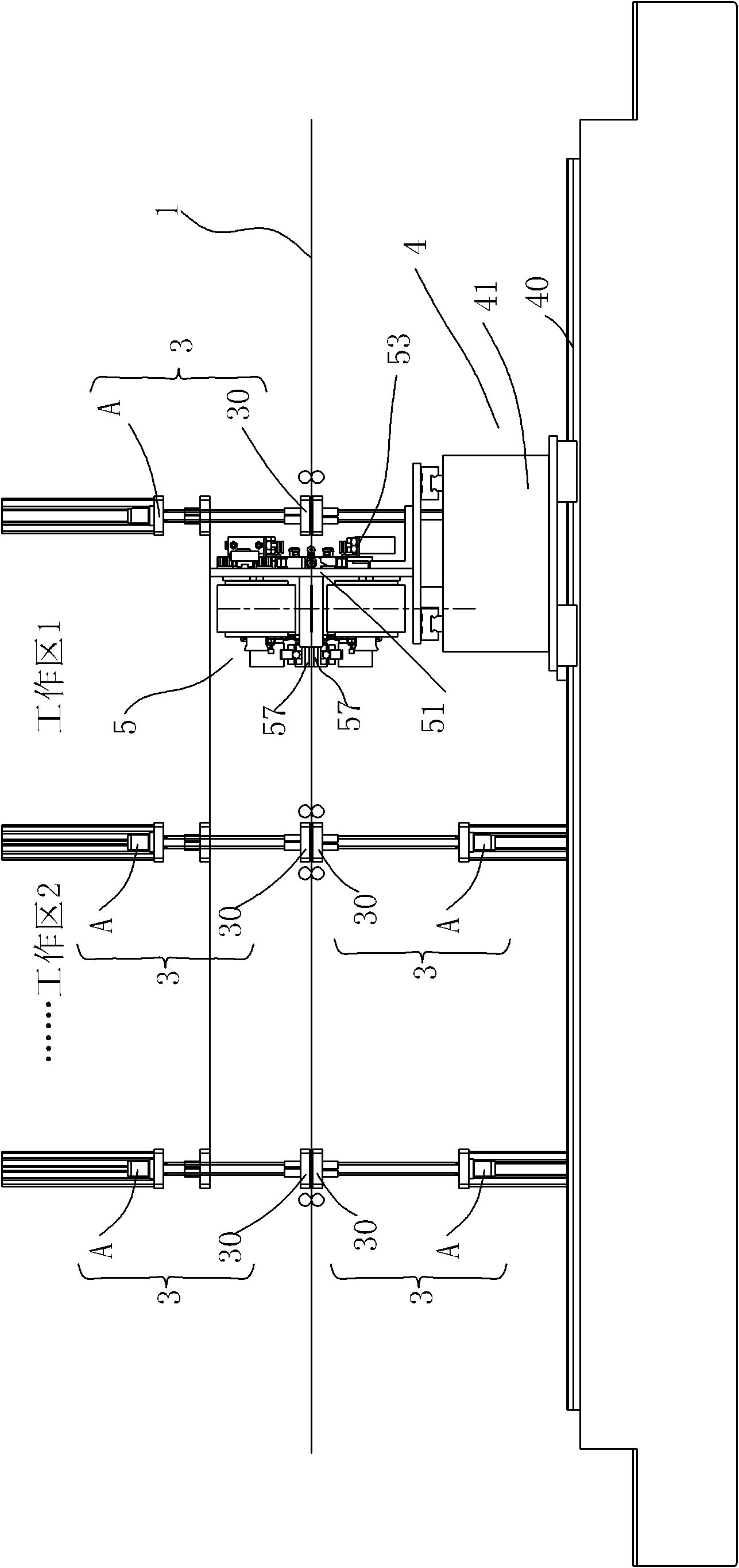

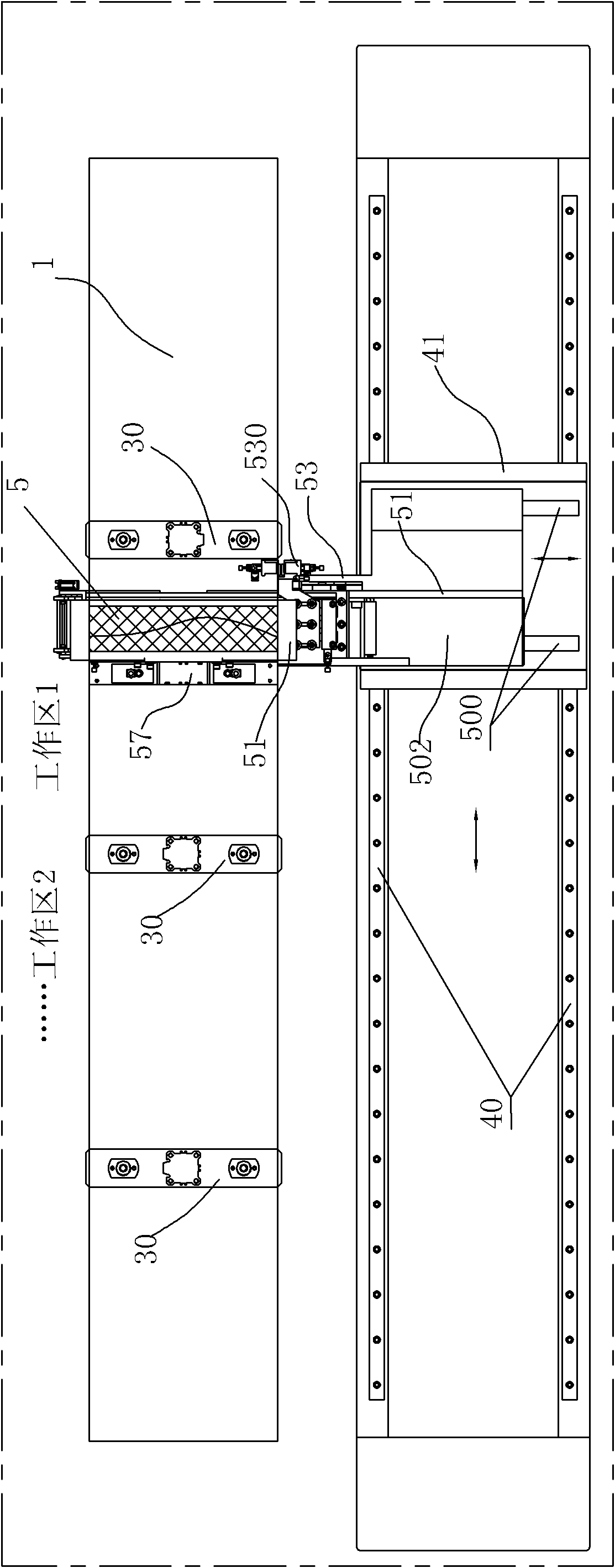

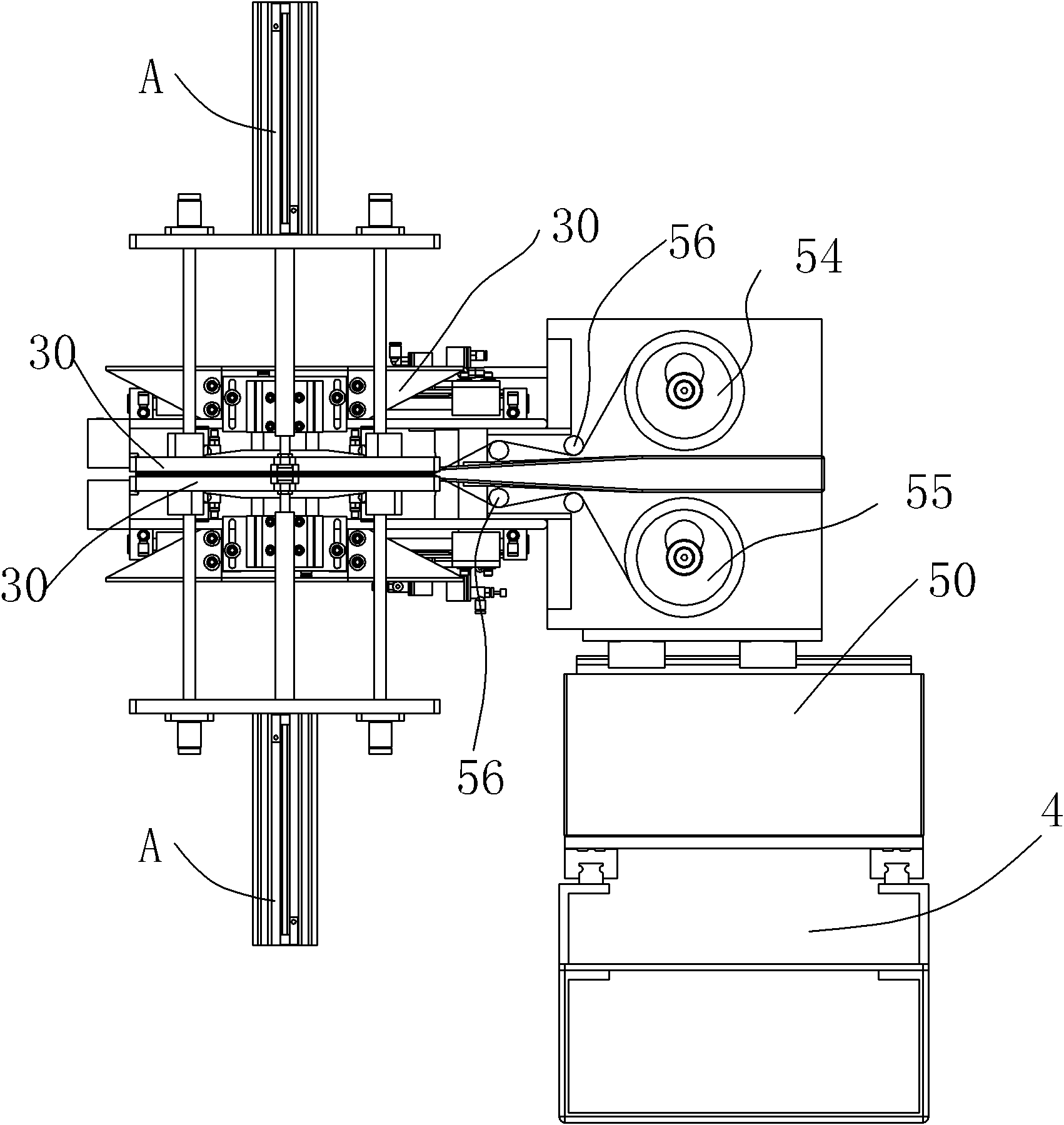

[0022] Such as Figure 1 to Figure 3 As shown, this embodiment provides a lithium battery pole piece automatic bonding machine, which is mainly used to illustrate the automatic bonding of the pole piece when a fracture occurs in the pole piece. A broken belt detection device 2 (not shown) that automatically detects a fracture in the pole piece belt is provided in the transmission work area of the pole piece belt, and the broken belt detection device 2 adopts an infrared sensing device that automatically detects a fracture in the pole piece belt. ; In the transmission working area of the pole piece belt, there are also multiple sets of pole piece belt clamping devices 3 that are arranged correspondingly up and down at a certain interval and can automatically clamp and fix the upper and lower sides of the broken pole piece belt. The belt clamping device 3 includes a pole piece clamp 30 for clamping the pole piece belt 1 and a cylinder device A that drives the pole piece clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com