Assembly machine for draining pump valve body

A technology of assembly machine and drainage pump, which is applied in the direction of assembly machine, metal processing equipment, manufacturing tools, etc., can solve the problems of small installation space, easy deformation, difficult sealing ring, etc., to improve assembly efficiency and success rate, and improve labor health. Condition, the effect of avoiding hand contact with grease

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

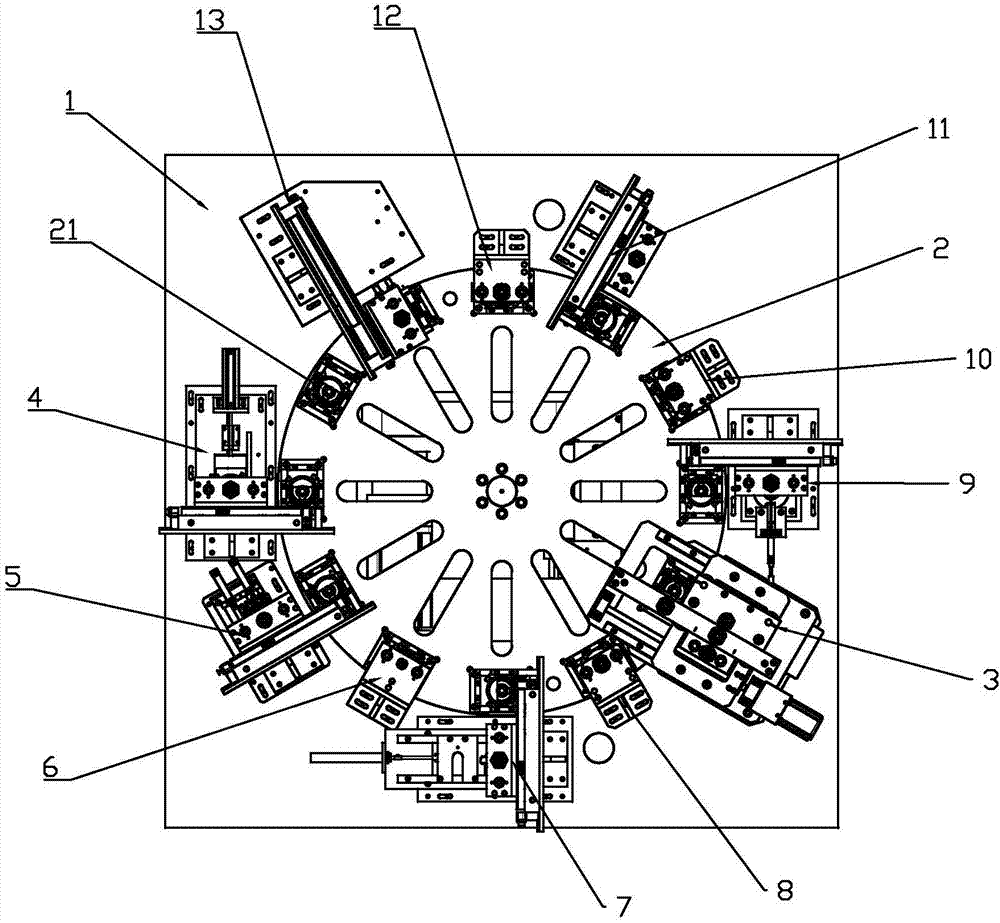

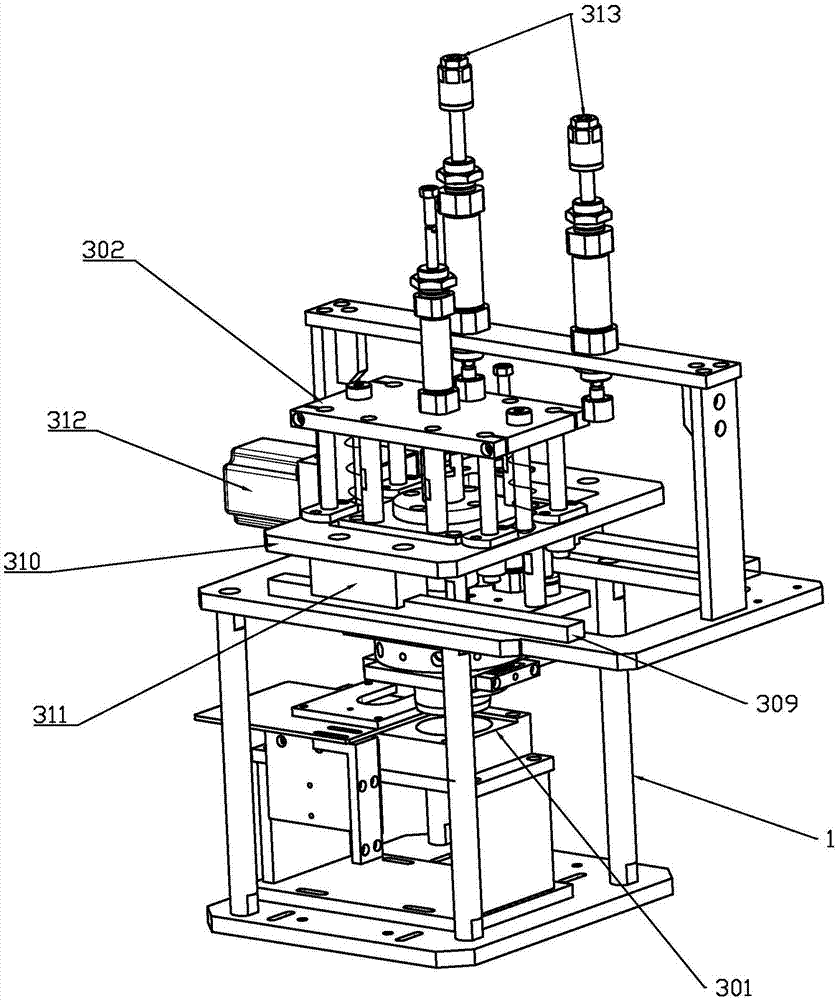

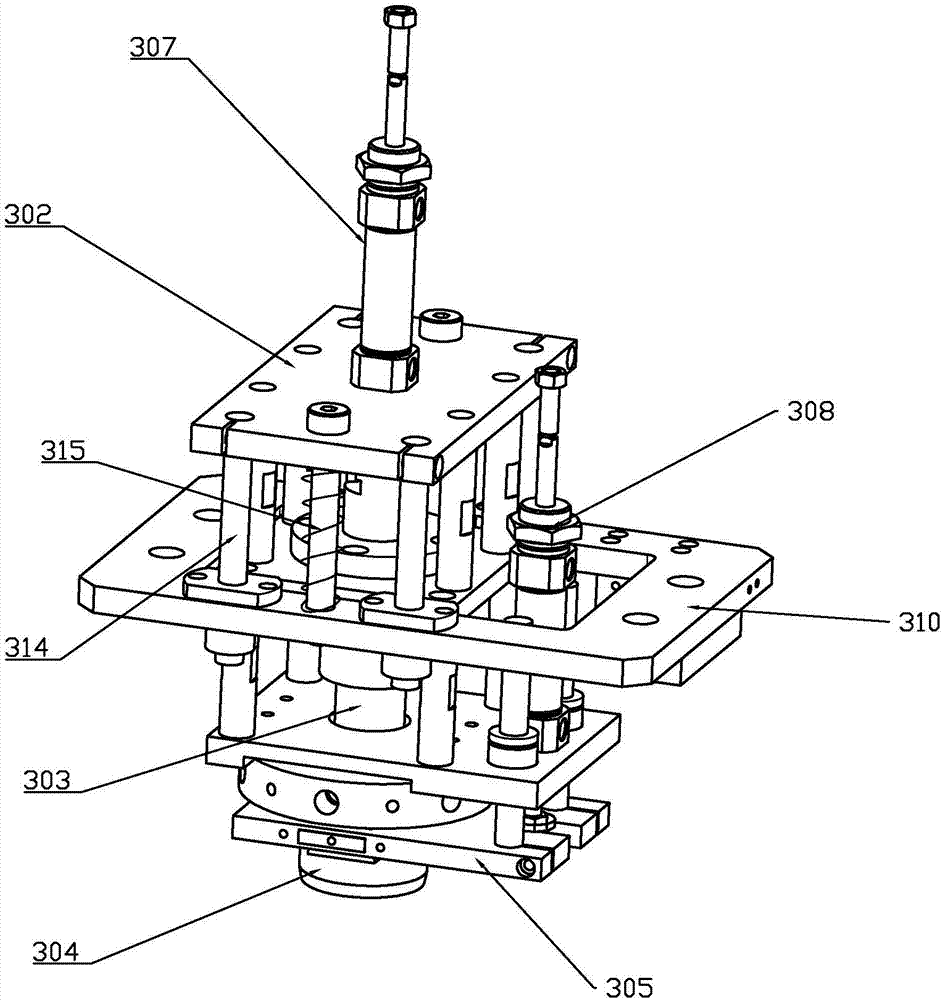

[0026] refer to Figures 1 to 4 , a drainage pump valve body assembling machine of the present invention includes a disk divider 2 installed on the frame 1, and a mounting table 21 evenly distributed on the disk divider 2, and also includes a The sealing ring installation station 3 on the outside of the disk divider 2, the sealing ring installation station 3 includes a sealing ring preset disk 301 arranged on the frame 1, located on the sealing ring preset disk The floating frame 302 above 301, the stretching mechanism and the scraping mechanism arranged on the floating frame 302, the first movement mechanism that drives the floating frame 302 to move radially along the disk divider 2, drives the The second movement mechanism for the floating frame 302 to move downward; the expansion mechanism includes a mandrel 303 with an outer tapered surface 3031 at the bottom, and a third drive component that drives the mandrel 303 to move up and down, and is arranged on the core The exp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com