Equipment suitable for automatic grinding of magnetic materials, and implementation method thereof

A magnetic material, automatic technology, applied in grinding/polishing equipment, metal processing equipment, parts of grinding machine tools, etc., can solve the problems of inconsistent grinding size, high labor intensity, low yield, etc. The effect of good consistency, low labor intensity and high grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

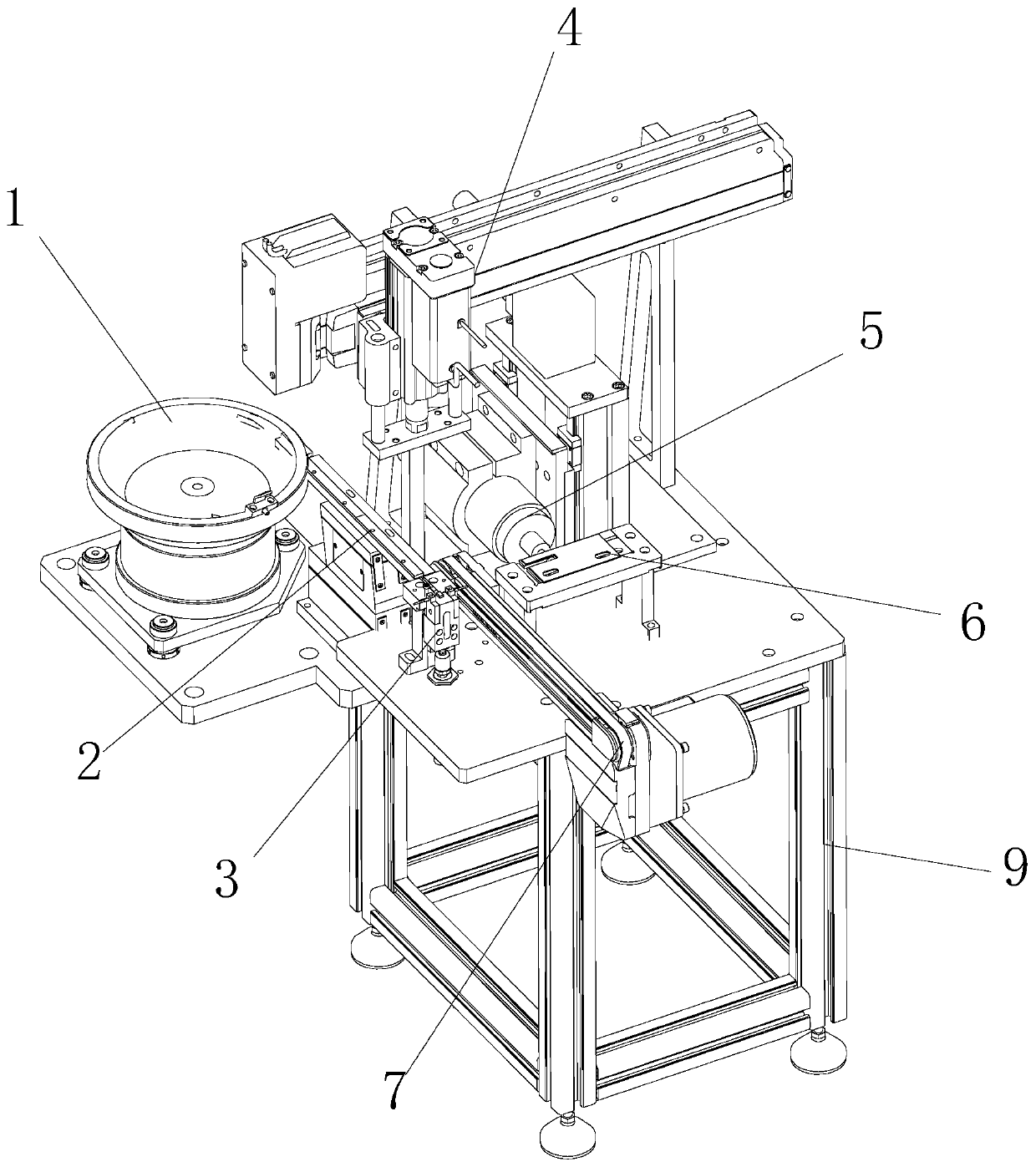

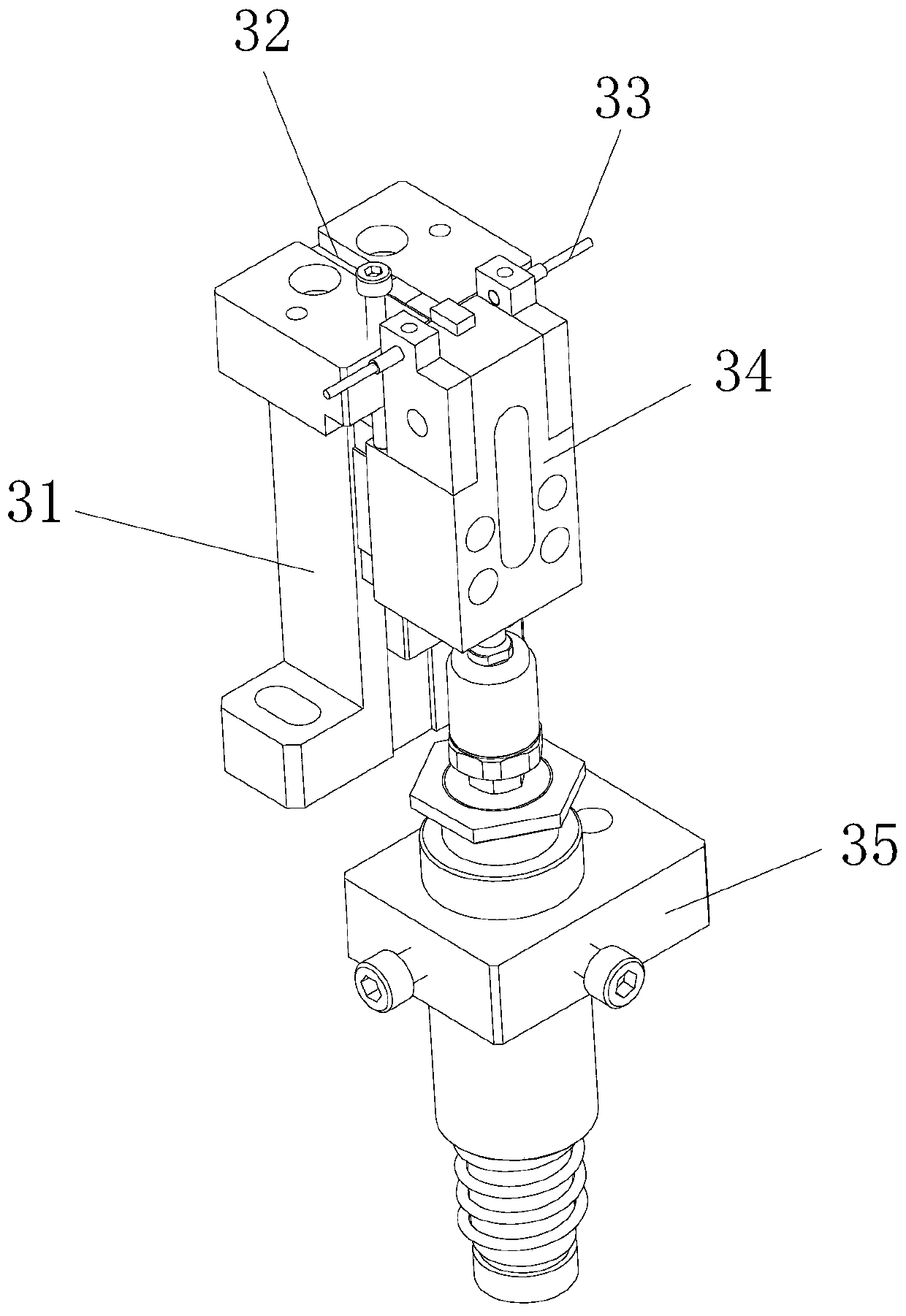

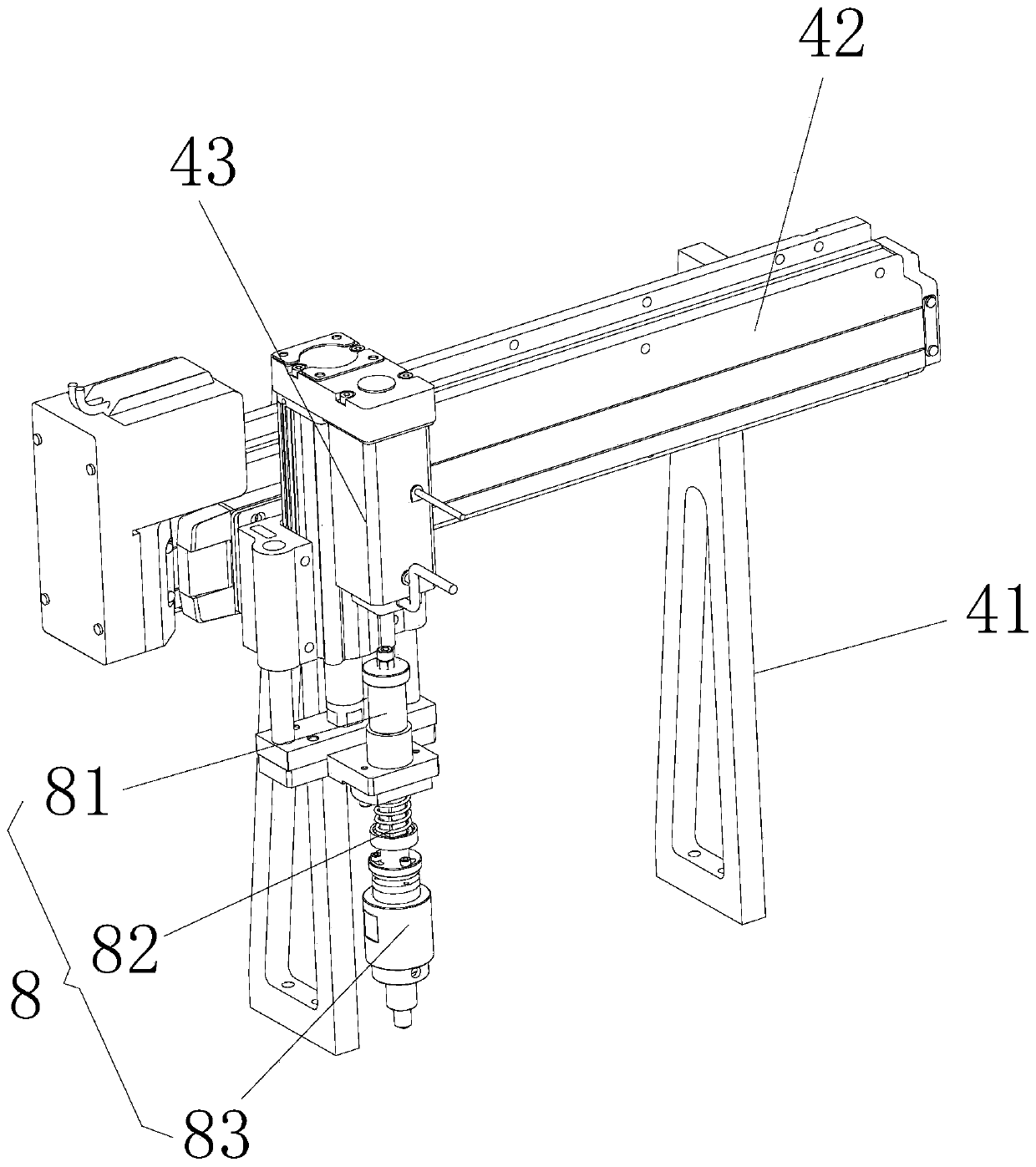

[0035] see Figure 1-5 , the present invention provides the following technical solutions: a device suitable for automatic grinding of magnetic materials, including a frame 9, a workpiece arrangement vibrating plate 1 is connected above the frame 9, and a material distribution mechanism is provided on one side of the workpiece arrangement vibrating plate 1 3. The material distribution mechanism 3 is connected with the workpiece arrangement vibrating plate 1 through the linear vibration feeding track 2, and one side of the linear vibration feeding track 2 is provided with a grasping and transplanting component 4, and the grasping and transplanting component 4 is connected with a suction cup component 8, A grinding wheel adjustment assembly 5 is provided below the grasping and transplanting assembly 4, and one end of the grinding wheel adjustment assembly 5 is provided with a grinding positioning platform 6, and one end of the grinding positioning platform 6 is provided with a gr...

Embodiment 2

[0048] The difference between this embodiment and Embodiment 1 is that further, the grinding positioning platform 6 includes a grinding positioning platform base 61, a positioning plate 62 and a U-shaped groove 63, wherein the grinding positioning platform base 61 is installed on the frame 9, and the grinding positioning platform A positioning plate 62 is connected above the positioning platform base 61 , and a U-shaped groove 63 is opened on the positioning plate 62 .

[0049] By adopting the above technical solution, the workpiece is positioned through the U-shaped groove 63 on the positioning plate 62 .

[0050] Further, the implementation method of the equipment suitable for automatic grinding of magnetic materials according to the present invention includes the following steps:

[0051] (1) The magnetic material workpieces enter the linear vibrating feeding track 2 and are transported forward sequentially after passing through the workpiece arrangement vibrating plate 1; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com