Automatic conveying and arrangement device of brake pads

A technology of automatic conveying and arranging devices, which is applied to conveyor objects, transportation and packaging, etc., can solve the problems of low brake pad efficiency and high labor cost, and achieve the effect of convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

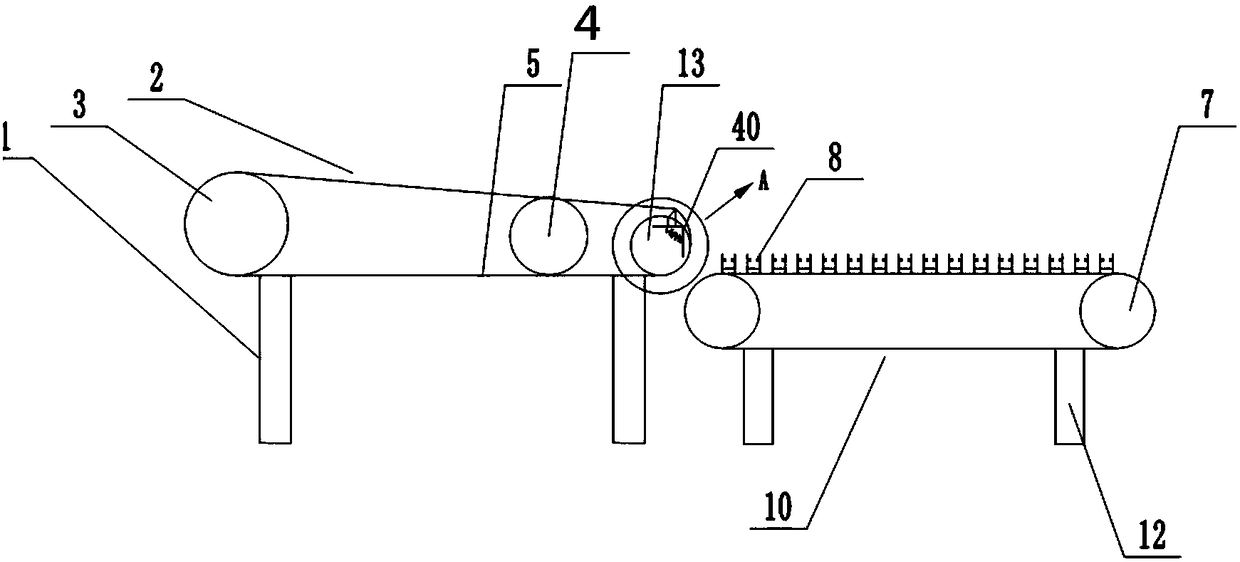

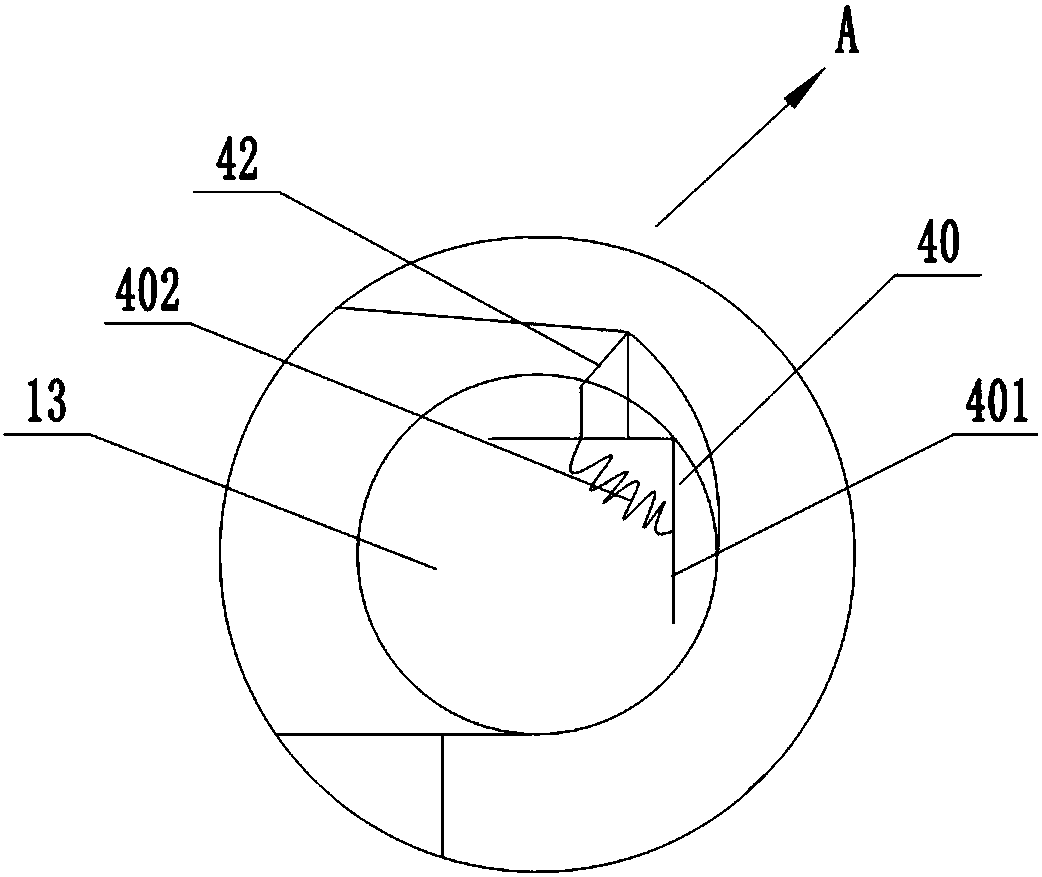

[0021] Brake pad automatic conveying and arranging device, such as figure 1 and figure 2 As shown, the first support 1 is provided with a conveyor platform 2, and the conveyor platform 2 includes a driving wheel 3, a driven wheel 4, a supporting wheel 13 and an A conveyor belt 5, and the A conveyor belt 5 is covered on the driving wheel 3, the driven wheel 4 and the supporting wheel 13 surfaces, between the driving wheel 3 and the driven wheel 4 are connected by a belt, a driving motor is arranged next to the driving wheel 3, the supporting wheel 13 does not rotate with the A conveyor belt 5, and the supporting wheel 13 is coated with lubricating oil to reduce the coefficient of friction, Arrangement platform 10 is positioned on the second support 12, and the left end of arrangement platform 10 is close to the support wheel 13 that is positioned at conveying platform 2 right-hand sides, and arrangement platform 10 comprises two transmission wheels 7 and the B conveyer belt 6 ...

Embodiment 2

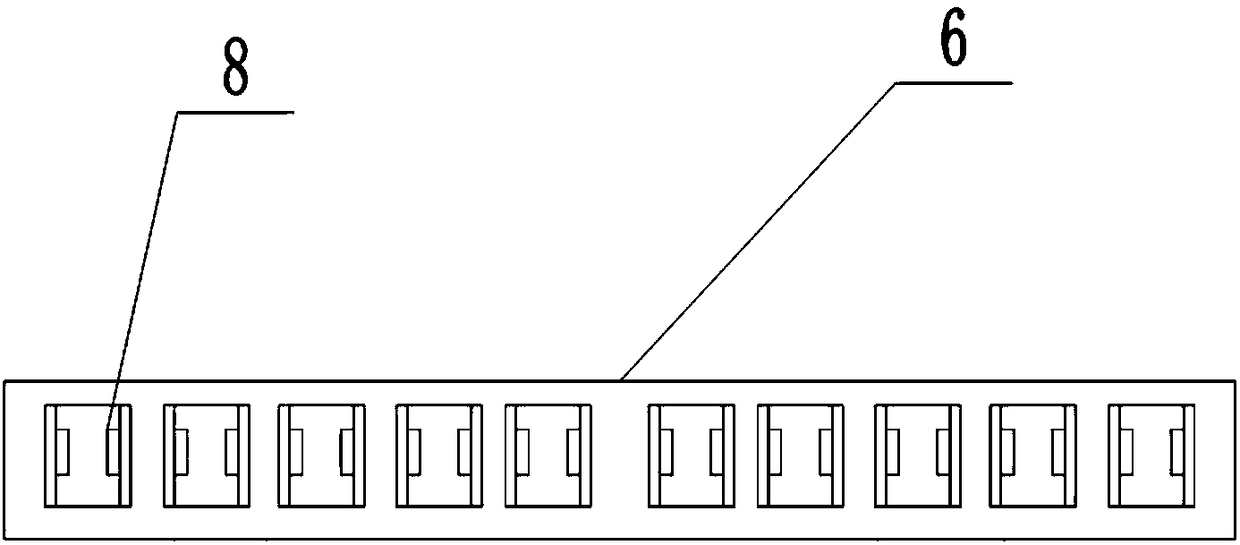

[0024] Brake pad automatic conveying and arranging device, such as Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that two sets of transmission wheels 7 covered by B conveyor belts are provided, and the two sets of transmission wheels 7 are placed in parallel, and the B conveyor belts on the two sets of transmission wheels 7 are located at the same On the horizontal plane, the positions of the positioning devices 8 on the two groups of B conveyor belts are in one-to-one correspondence.

[0025] During specific implementation, the positioning devices 8 on the two groups of B conveyor belts push forward and clamp the two ends of the brake pads, so as to avoid the situation that one positioning device 8 cannot push the brake pads because the brake pads are too heavy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com