Ceramic column grid array packaging and column planting device

A ceramic pillar grid array and pillar planting technology, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as welding pillar damage, and achieve the effects of good product consistency, improved work efficiency, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further introduced below in combination with specific embodiments.

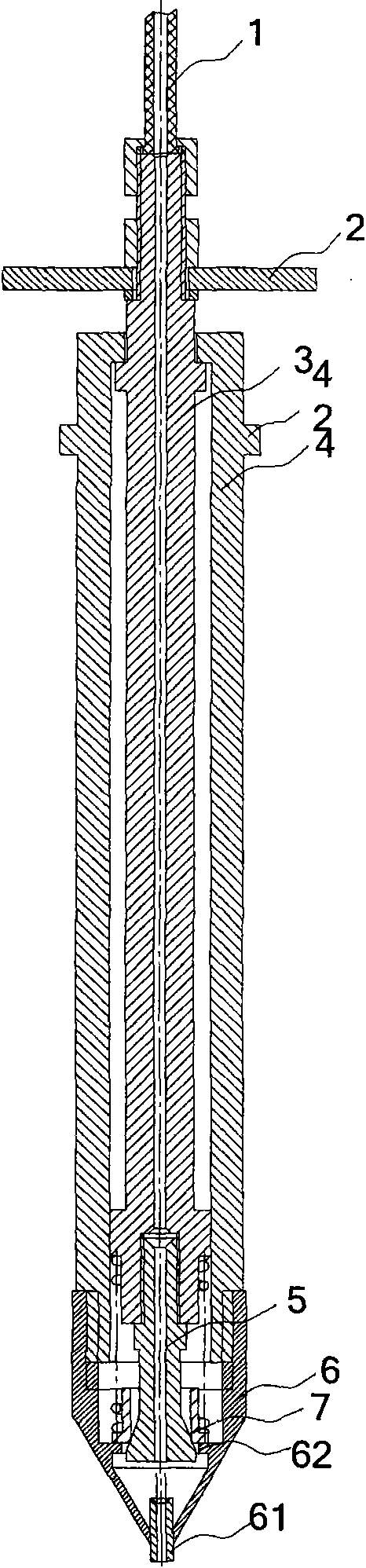

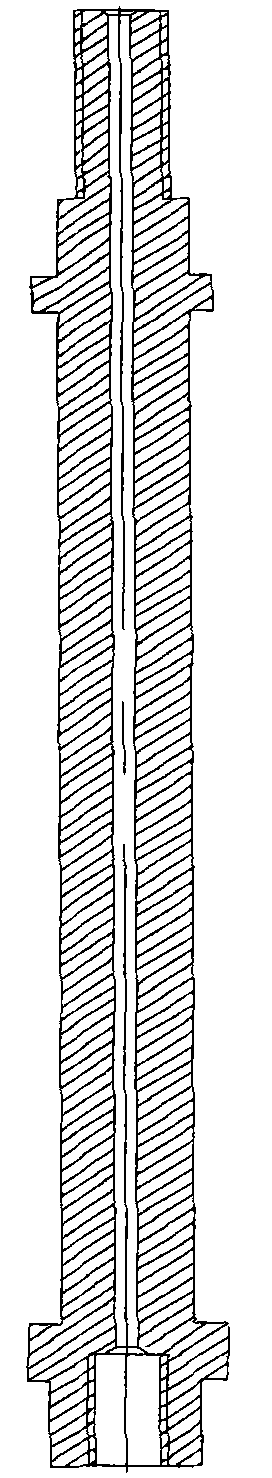

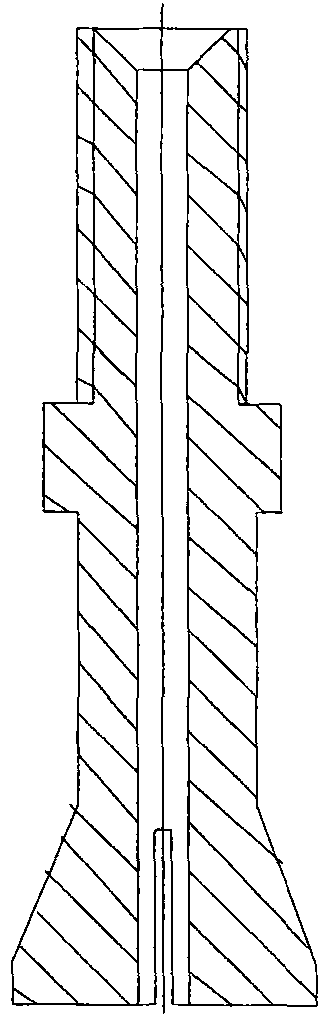

[0022] Such as figure 1 , is a cross-sectional view along the axis of the ceramic column grid array packaged column planting device according to the present invention, including: a feeding tube 1, a silo 3, a casing 4, a valve 5 and a cap 6, and also includes a pressure plate 2 and a ferrule 7.

[0023] Among them, the feeding pipe 1 is a flexible pipe with two ends open, which is used to fill the solder to the column planting device; The axial direction is arranged up and down in sequence; the valve 5 is a switch device used to control the output of the welding column, and within a suitable time interval, each time the valve is opened, a welding column can be sent out; the jacket 4 and the cap 6 are used to cover the material bin 3 and The valve 5; the cap 6 has a discharge opening 61 opposite to the opening of the valve. In this embodiment, the pressing plate 2 is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com