Feeding mechanism of universal joints

A technology of feeding mechanism and universal joint, which is applied in the direction of conveyors, conveyor objects, rotary conveyors, etc., can solve the problems of raw material collision, affecting the processing efficiency of universal joints, vibration, etc., and achieve the effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

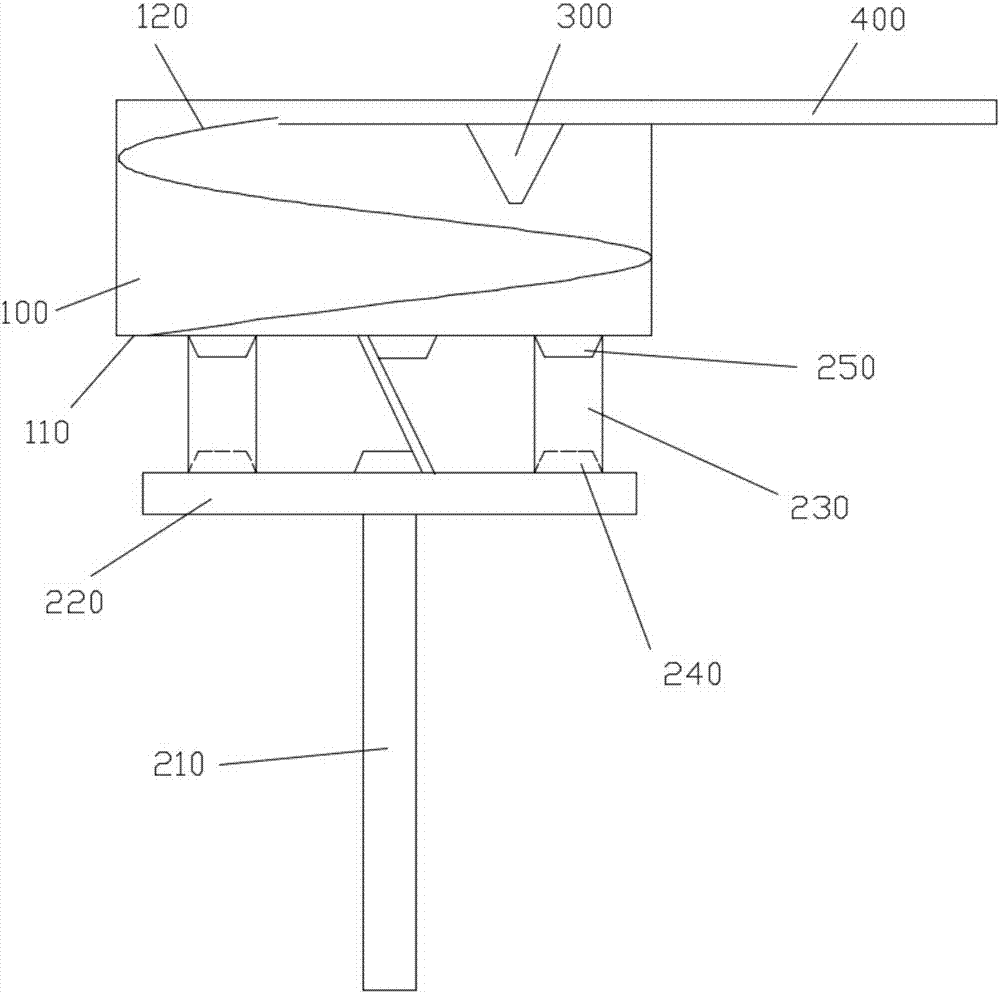

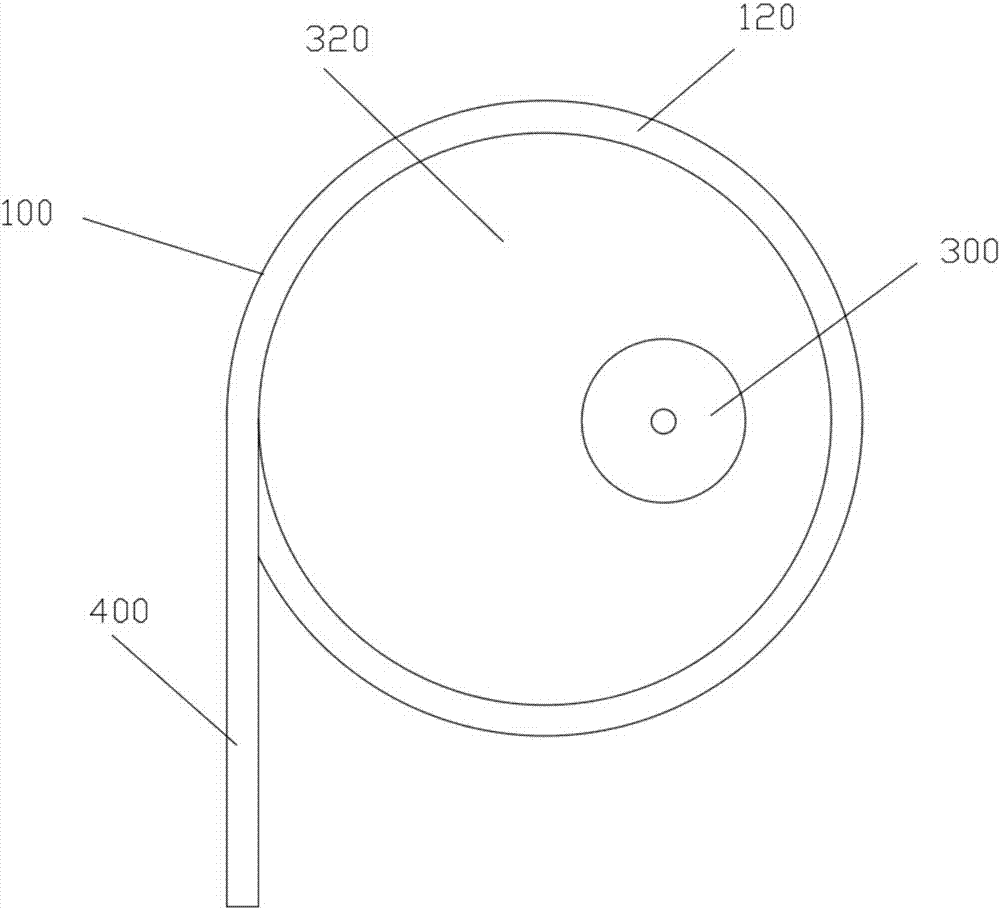

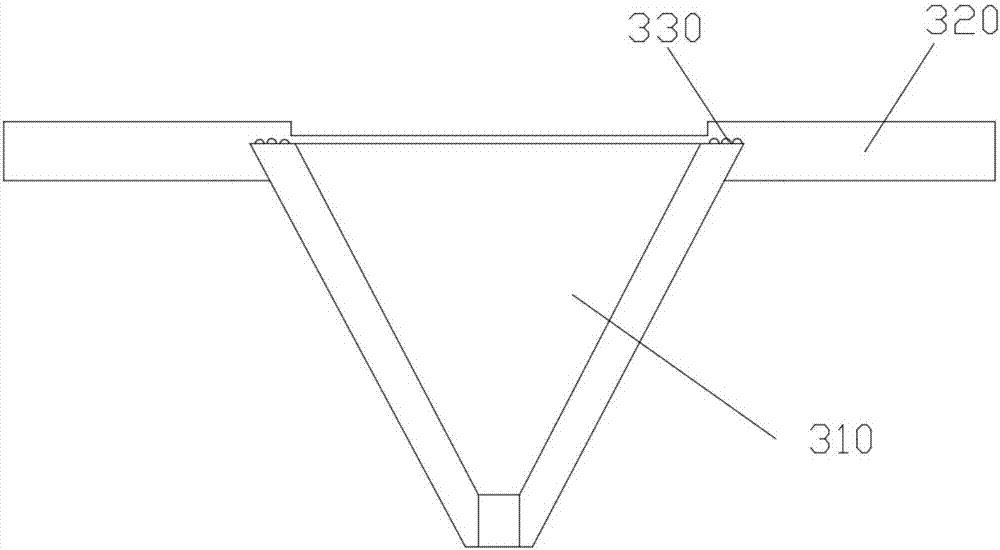

[0025] like figure 1 As shown, a feeding mechanism of a universal joint includes a barrel body 100, a rotating plate 110, a rotating assembly, a funnel assembly 300, and a feeding trough 400; the rotating plate 110 is located at the bottom of the barrel body 100, and the rotating plate 110 and the barrel body 100 rotating connection; the rotating assembly is located under the rotating plate 110, and the rotating assembly and the rotating plate 110 rotate synchronously; the funnel assembly 300 faces the barrel body 100, and the funnel assembly 300 is rotationally connected with the barrel body 100, and the inner wall of the barrel body 100 is provided with a transmission groove 120 , the initial position of the transfer trough 120 matches the position of the funnel 310 .

[0026] A bracket 320 is provided between the funnel assembly 300 and the barrel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com