Columnar magnet arranging device and method

A technology for arranging devices and magnets, which is applied in the field of automation, can solve problems such as inability to arrange magnetic rings at intervals, and cannot meet spraying requirements, so as to reduce labor intensity and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

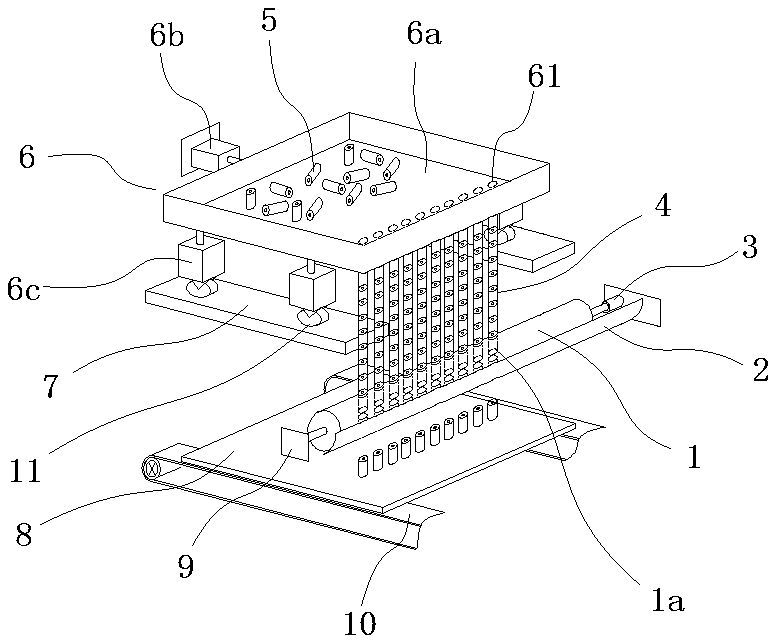

[0024] Such as figure 1 In the shown embodiment, a columnar magnet arrangement device includes a vibrating table 6 , a rotating shaft 1 and a conveying plate 8 . The vibrating table includes a table top 6a, a side cylinder 6b and a bottom cylinder 6c. The four sides of the table top are respectively provided with ribs to form a space for accommodating the columnar magnet 5. One side of the bottom of the table is provided with a row of guide holes 61. The guide holes are arranged along the edge of the table. The centers of the guide holes are located on the same straight line. The lower part of each guide hole is respectively provided with a corresponding communicating conduit 4. The side cylinder is horizontally arranged on the opposite side of the side where the guide hole of the table is located, and the end of the piston rod of the side cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com