Chain saw

A technology of chain saws and sprockets, which is applied in the field of chain saws and can solve the problems of affecting the service life of sawing chains and low sawing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

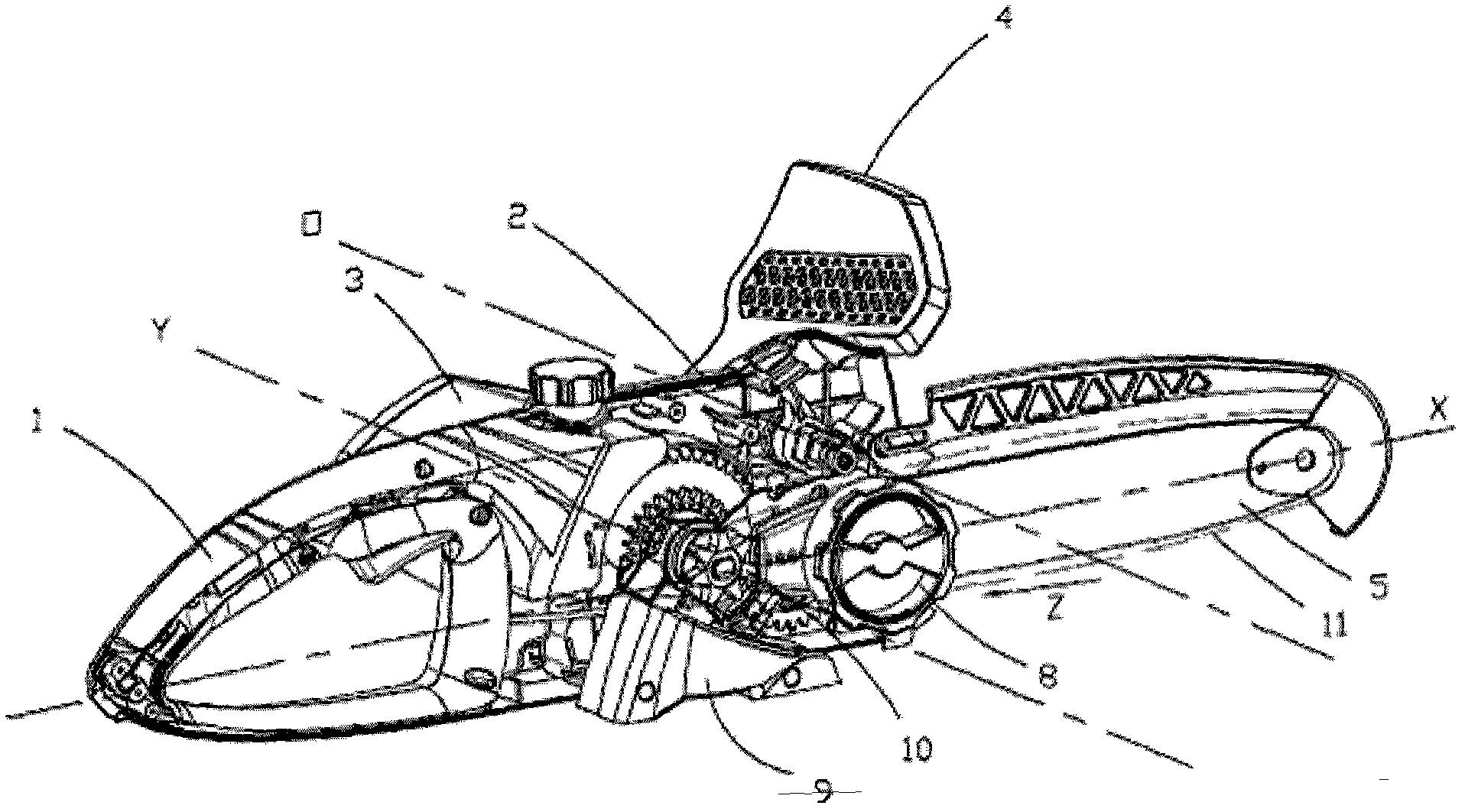

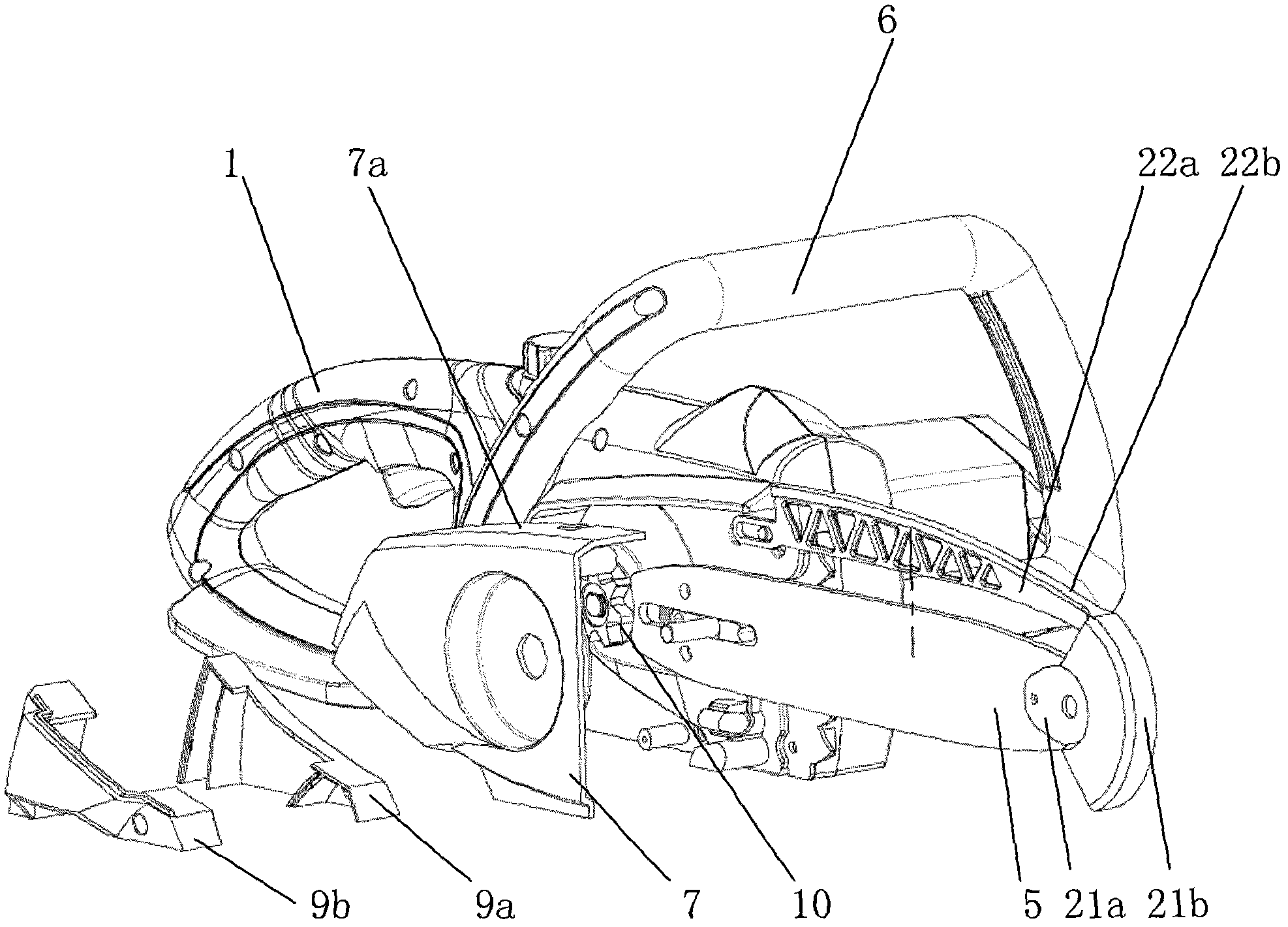

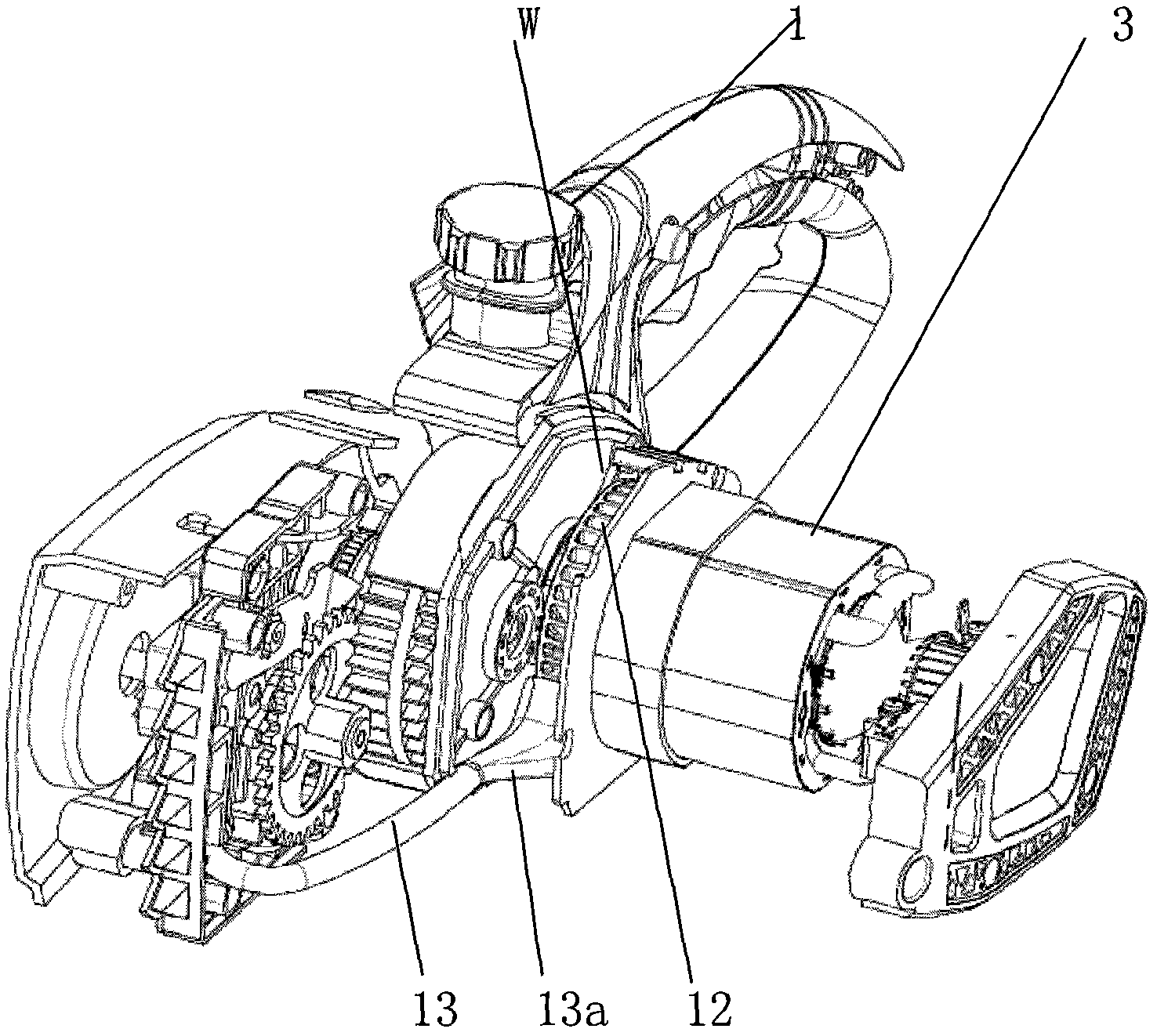

[0023] Such as figure 1 , 2, 3, and 16 show that the chain saw of a preferred embodiment of the present invention comprises a casing 2, a rear handle 1 connected to the rear end of the casing 2, and a rear handle 1 fixedly mounted on the casing 2 and close to the casing 2 The front handle 6 of the front end of the front end, an anti-rebound shield 4 is firstly rotated and mounted on the front end of the casing 2, and the casing 2 forms a long axis X extending along the front and rear handle directions. The chain saw also includes a motor 3 installed in the casing 2, the motor 3 has a motor shaft (not shown in the figure), preferably, the Y axis is perpendicular to the X axis. A sprocket 10 is installed on the output shaft 34 along the Y-axis direction, and the motor 3 drives the sprocket 10 to rotate through a transmission mechanism connecting the output shaft 34 and the motor shaft. The transmission mechanism can be a planetary gear structure or other reduction gears institu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com