Computer numerical control saw

An electronic cutting saw and saw blade technology, which is applied in the direction of circular saws, sawing components, sawing equipment, etc., can solve the problems of single thickness and the height of the saw blade cannot rise and fall with the thickness of the plate, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

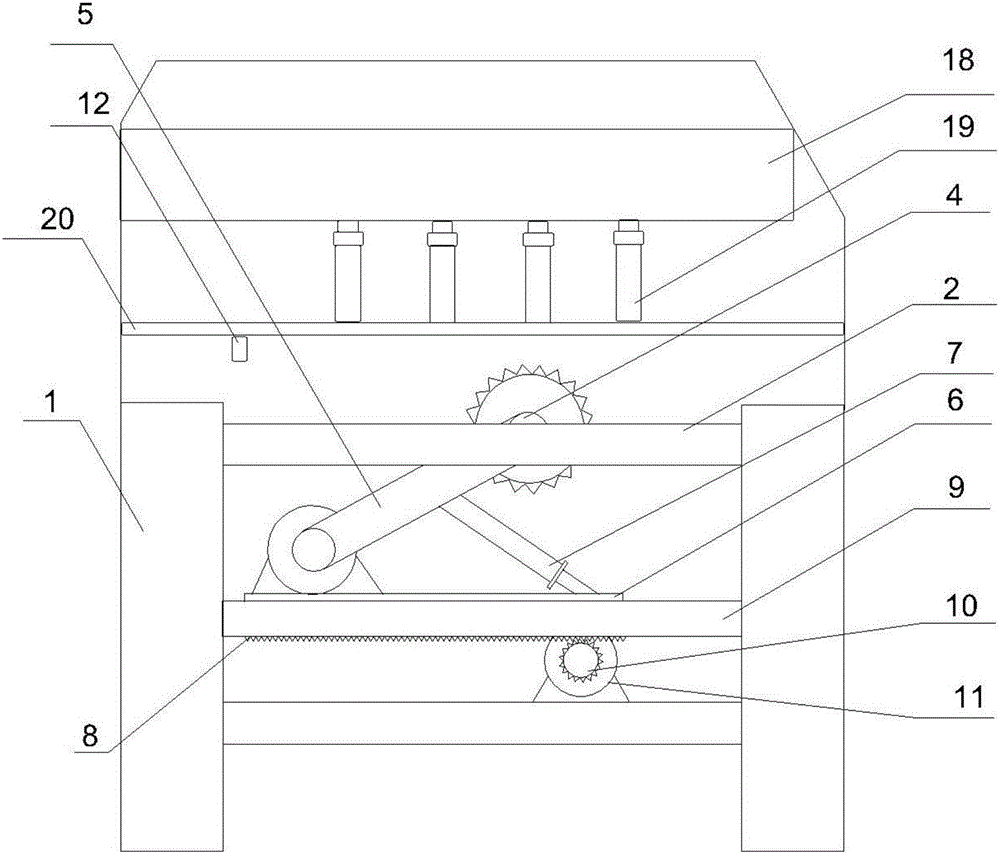

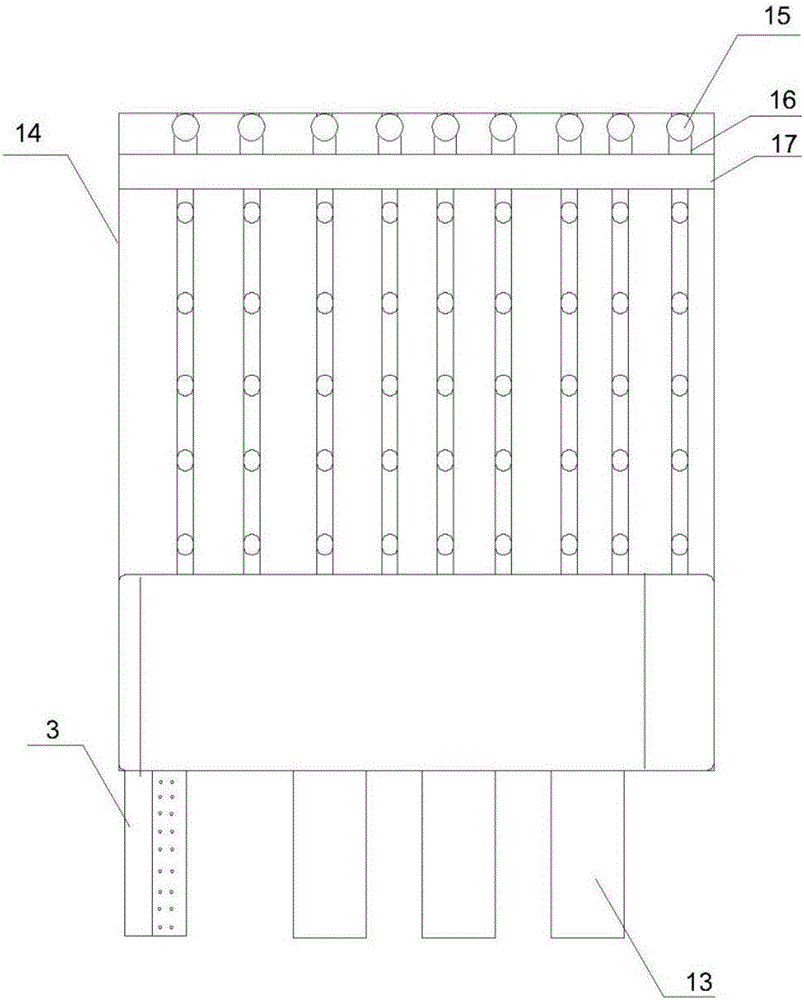

[0025] An electronic cutting saw, comprising a frame 1, a workbench 2 arranged on the frame 1, and an electric control cabinet 3, the frame 1 is provided with a mounting beam 9, and the lower side of the workbench 2 is provided with a saw blade drive system, the saw blade drive system includes a saw blade drive motor 4, the saw blade drive motor 4 is connected to the connecting rod 5, the connecting rod 5 is hinged on the saw blade support platform 6, the middle part of the connecting rod is connected to the side thrust cylinder 7, and the saw blade is supported A rack 8 is arranged on the platform, and rollers are arranged parallelly on both sides of the saw blade support platform 6. The saw blade support platform 6 is arranged on the installation beam 9, and the installation beam 9 is provided with sliding tracks corresponding to the rollers; the saw blade supports The rack 8 of the table 6 meshes with the gear 11 of the displacement motor 10 ; a distance sensor 12 is provide...

Embodiment 2

[0027] An electronic cutting saw, comprising a frame 1, a workbench 2 arranged on the frame 1, and an electric control cabinet 3, the frame 1 is provided with a mounting beam 9, and the lower side of the workbench 2 is provided with a saw blade drive system, the saw blade drive system includes a saw blade drive motor 4, the saw blade drive motor 4 is connected to the connecting rod 5, the connecting rod 5 is hinged on the saw blade support platform 6, the middle part of the connecting rod is connected to the side thrust cylinder 7, and the saw blade is supported A rack 8 is arranged on the platform, and rollers are arranged parallelly on both sides of the saw blade support platform 6. The saw blade support platform 6 is arranged on the installation beam 9, and the installation beam 9 is provided with sliding tracks corresponding to the rollers; the saw blade supports The rack 8 of the table 6 meshes with the gear 11 of the displacement motor 10 ; a distance sensor 12 is provide...

Embodiment 3

[0030] An electronic cutting saw, comprising a frame 1, a workbench 2 arranged on the frame 1, and an electric control cabinet 3, the frame 1 is provided with a mounting beam 9, and the lower side of the workbench 2 is provided with a saw blade drive system, the saw blade drive system includes a saw blade drive motor 4, the saw blade drive motor 4 is connected to the connecting rod 5, the connecting rod 5 is hinged on the saw blade support platform 6, the middle part of the connecting rod is connected to the side thrust cylinder 7, and the saw blade is supported A rack 8 is arranged on the platform, and rollers are arranged parallelly on both sides of the saw blade support platform 6. The saw blade support platform 6 is arranged on the installation beam 9, and the installation beam 9 is provided with sliding tracks corresponding to the rollers; the saw blade supports The rack 8 of the table 6 meshes with the gear 11 of the displacement motor 10 ; a distance sensor 12 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com