Rotating disc type slicer

A technology of turntable and slicer, which is applied in metal processing and other fields, and can solve problems such as user troubles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

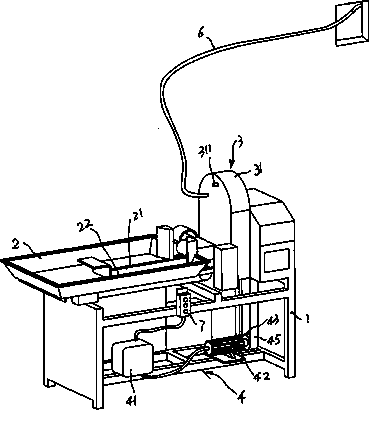

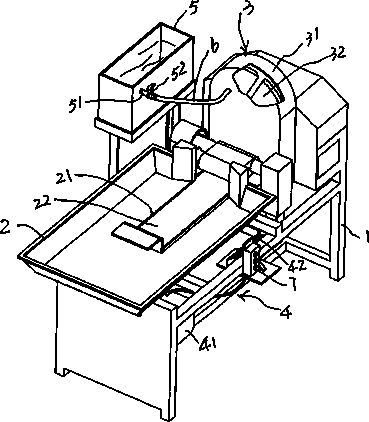

[0025] A kind of turntable slicer of the present invention comprises frame 1, tray 2, cutter box 3, power transmission mechanism 4, water tank 5; Tray 2 is fixed on frame 1 top, and the inner end of this tray 2 is provided with discharge port not shown), the bottom is provided with a groove 21, and a material propulsion mechanism is provided in the groove. The material propulsion mechanism is composed of a pair of drive wheels connected to the motor and a transmission belt 22 arranged between the drive wheels. The material is placed in the tray. The material is pushed forward by the conveyor belt 22 of the material propulsion mechanism, and enters into the knife box 3 from the discharge port. The knife box 3 includes a box body 31 and a rotary blade 32 arranged in the box body. The casing 31 is adjacent to the tray 2, and the upper part of the casing is provided with an air hole and a water inlet hole, and the water inlet hole connects the water inlet pipe 6 to the water t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com