Biological experiment slicing device

A slicing device and bio-experimental technology, which is applied in metal processing and other directions, can solve the problems of inability to accurately adjust the slice thickness, uneven slice thickness, and incomplete tissue cut, so as to improve slice quality and practicability, improve slice efficiency, size, etc. same effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

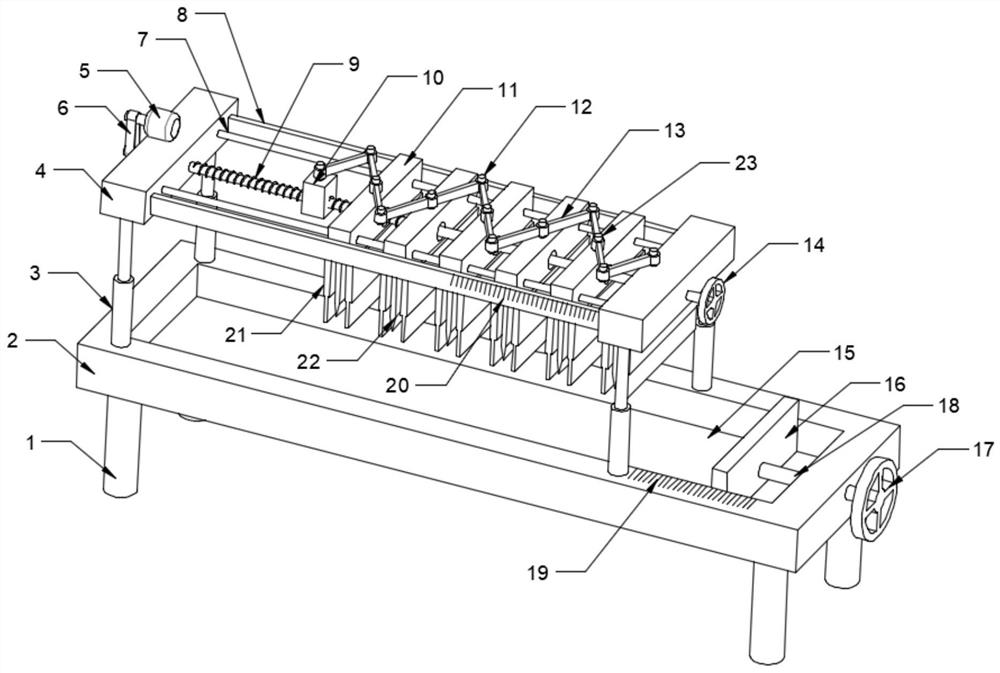

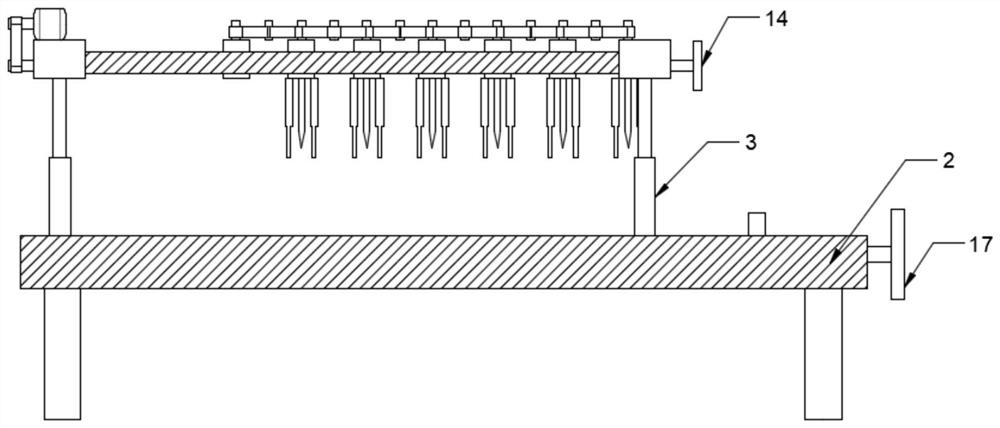

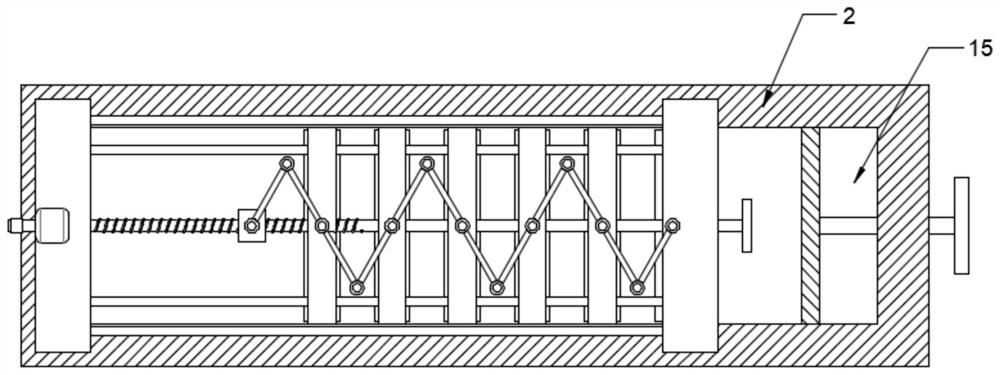

[0025] see Figure 1-4 , a biological experiment slicing device, including a column 1 and a placement plate 2, the placement plate 2 is provided with a slicing assembly, the specific type of the slicing assembly is not limited, in this embodiment, preferably, the slicing assembly includes a cylinder 3 , mounting plate 4, guide rod 7, screw mandrel 9, slide block 10, adjustment block 11, limit pin 12, connecting rod 13, cutter 22 and rotating shaft 23, the two ends of two mounting plates 4 are installed by cylinder 3 On the placement plate 2, the two ends of the two guide rods 7 are fixedly installed on the two mounting plates 4, and a plurality of adjustment blocks 7 are movably sleeved on the upper and middle parts of the guide rods 7. There are through holes, and the screw rods 9 run through the through holes. , the two ends are rotatably installed in the two mounting plates 4 and one end extends to the outside of the mounting plate 4 and is connected with a drive member, th...

Embodiment 2

[0034]In order to improve the quality of slicing, this embodiment is further improved on the basis of Embodiment 1. The improvement is that: the two sides of the cutter 22 are provided with pressing plates 21, and the specific type of the pressing plate 21 is not limited. In this embodiment, Preferably, the pressing plate 21 includes a sleeve plate 2101, a pressing plate 2102 and a return spring 2103, the sleeve plate 2101 is fixedly installed on the adjustment block 11, and the upper end of the pressing plate 2102 is movably sleeved in the sleeve plate 2101 and between the sleeve plate 2101 A return spring 2103 is provided, and when the cylinder 3 works, the pressing plate 2102 first contacts with the article to be cut and fixes it, and then during the descent of the cutter 22, the return spring 2103 is compressed to make the article firmly fixed before slicing. Improved slice quality and usability.

[0035] To sum up, by setting the slicing component, when slicing the item, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com