Taro cutting machine

A taro and slicer technology, which is applied in metal processing and other directions, can solve problems such as inability to cut taro, unsuitable taro, and complex structure, and achieve the effects of improving slice quality, avoiding hand injuries, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

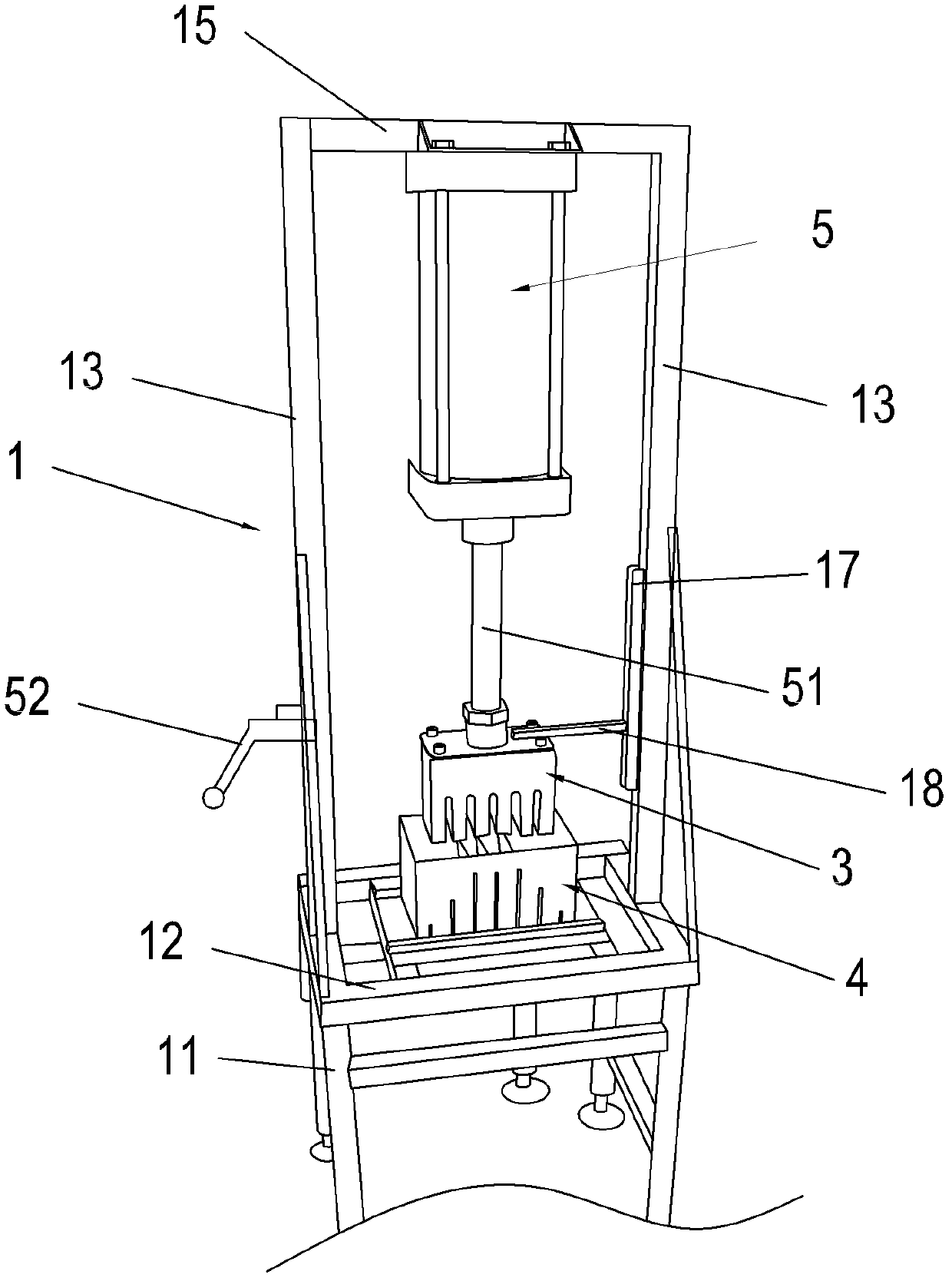

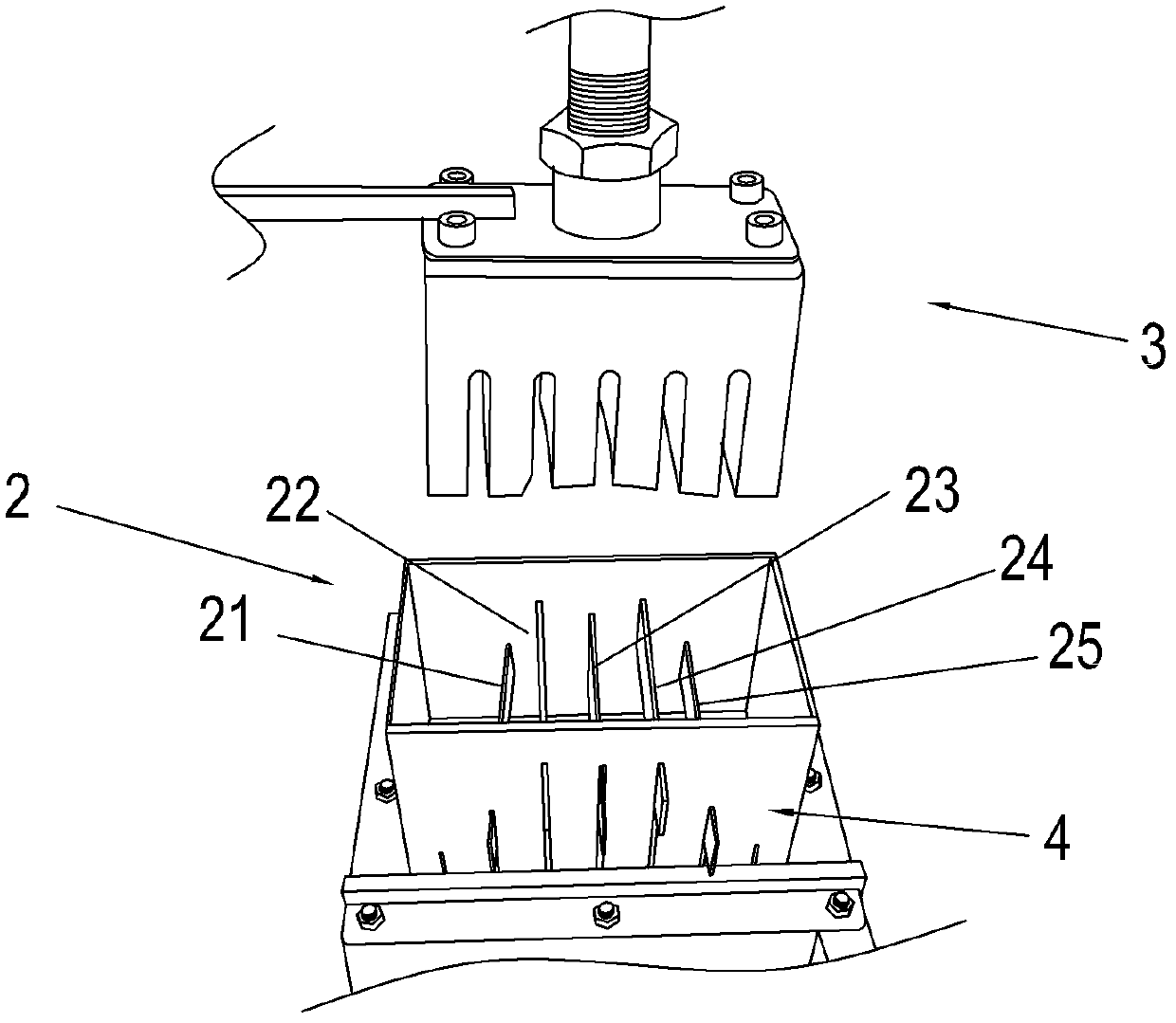

[0031] For specific embodiments of the present invention, refer to Figure 1 to Figure 3 , a taro cutting machine mainly consists of a bracket 1 and a slicer, wherein the slicer includes a knife set 2 and a pressing block 3, and the knife set 2 is arranged in a square frame 4.

[0032] This support 1 comprises a platform 12, and its center is provided with slicing device 2; Rod 15 is connected, and a cylinder 5 is fixed under cross bar 15, and the end of the push rod 51 of cylinder 5 fixes briquetting block 3, and the position of this briquetting block 3 and the position of square frame 4 match correspondingly. The support rod 13 on the left is also provided with an operation switch 52 for controlling the operation of the cylinder 5 .

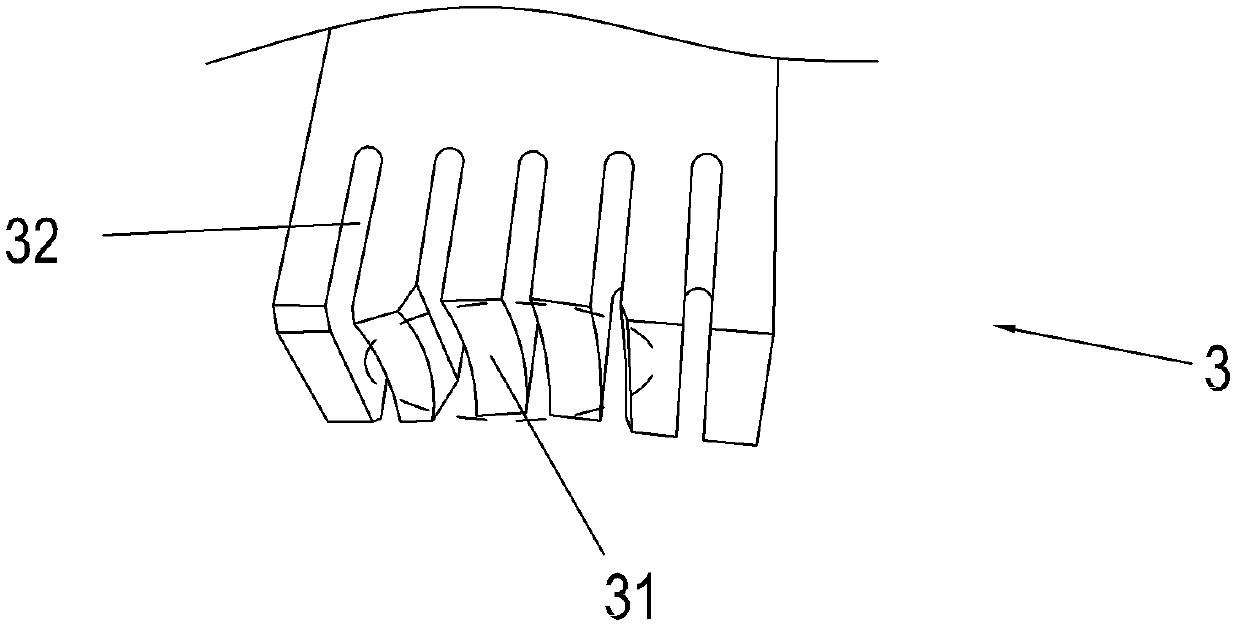

[0033] In this embodiment, the cutter set includes five cutters 21 , 22 , 23 , 24 and 25 . The square frame 4 is open up and down, and on the opposite front and rear side walls, five tool jacks are set horizontally, namely the jacks 41, 42, 4...

Embodiment 2

[0038] The implementation of this embodiment is basically the same as that of Embodiment 1, the difference is that in this embodiment, the positions of the knives are different, specifically: the upper row is the knives 21, 25, and the lower row is the knives 22, 24 , the middle is cutter 23. For the corresponding socket arrangement, see Figure 5 . And there is a stagger between the upper and lower rows of tool sockets (see the dotted line in the figure), the cutter is in the shape of a rectangular parallelepiped, there are no protrusions at both ends, and the width is the same as the socket, so that the tools are also staggered by about 0.5cm after insertion .

Embodiment 3

[0040] see Figure 6, the implementation of this embodiment is basically the same as that of Embodiment 1, the difference is that in this embodiment, the square frame 4 is provided with upper, middle and lower rows of tool insertion holes on the vertical plane, and each row has A plurality of sockets 41, when in use, the cutter can be inserted in different sockets as required. That is, in this implementation, the number of tool insertion holes is greater than the number of tools. Can be on the same vertical line (or mutually staggered) between the upper and lower rows of jacks. The thickness of the slice can be adjusted by inserting the knife in different positions. In addition, the jacks 41 can also be arranged in more rows on the vertical plane, such as 4 rows or 5 rows, whereby each taro can be cut into more slices. The shape of the square frame can also be changed to other shapes, as long as the inside can accommodate taro to pass through.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com