Silicon carbide ingot slicing device and silicon carbide ingot slicing method

A silicon carbide crystal and silicon carbide technology is applied in the field of silicon carbide crystal rod slicing equipment and the slicing field of silicon carbide crystal rods, which can solve the problems of broken cutting lines, poor slicing quality of silicon carbide crystal rods, etc., and achieves an improved slicing quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

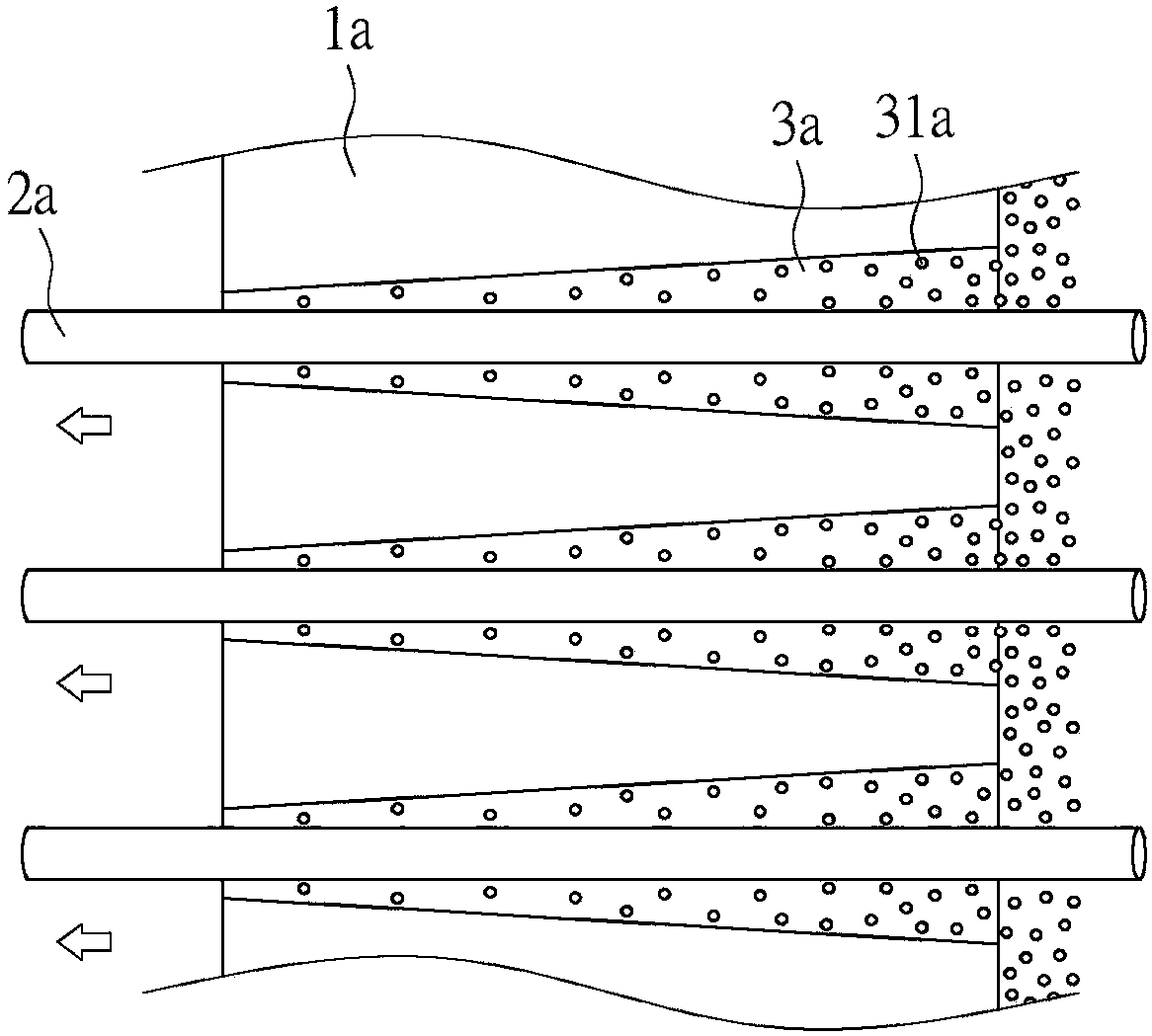

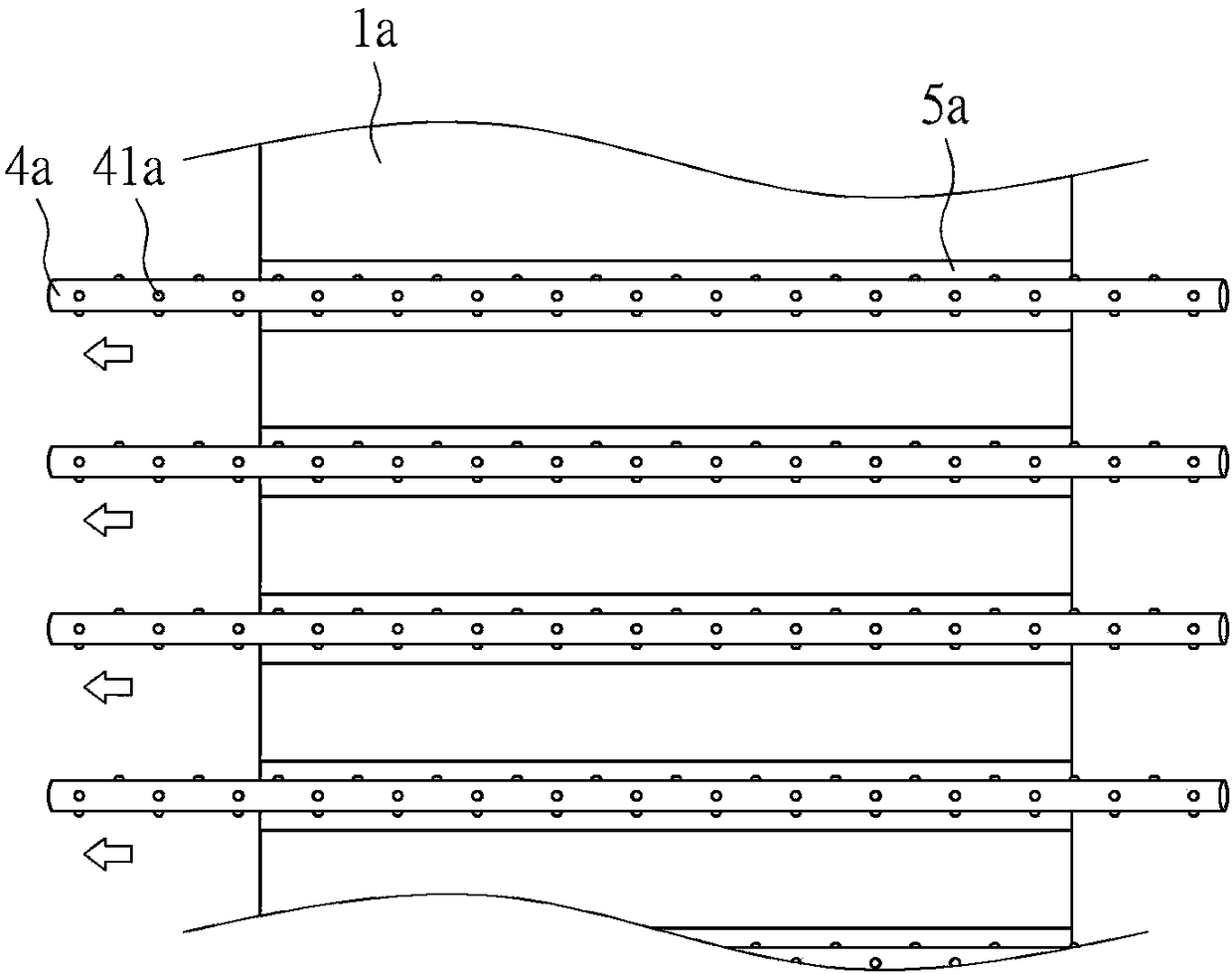

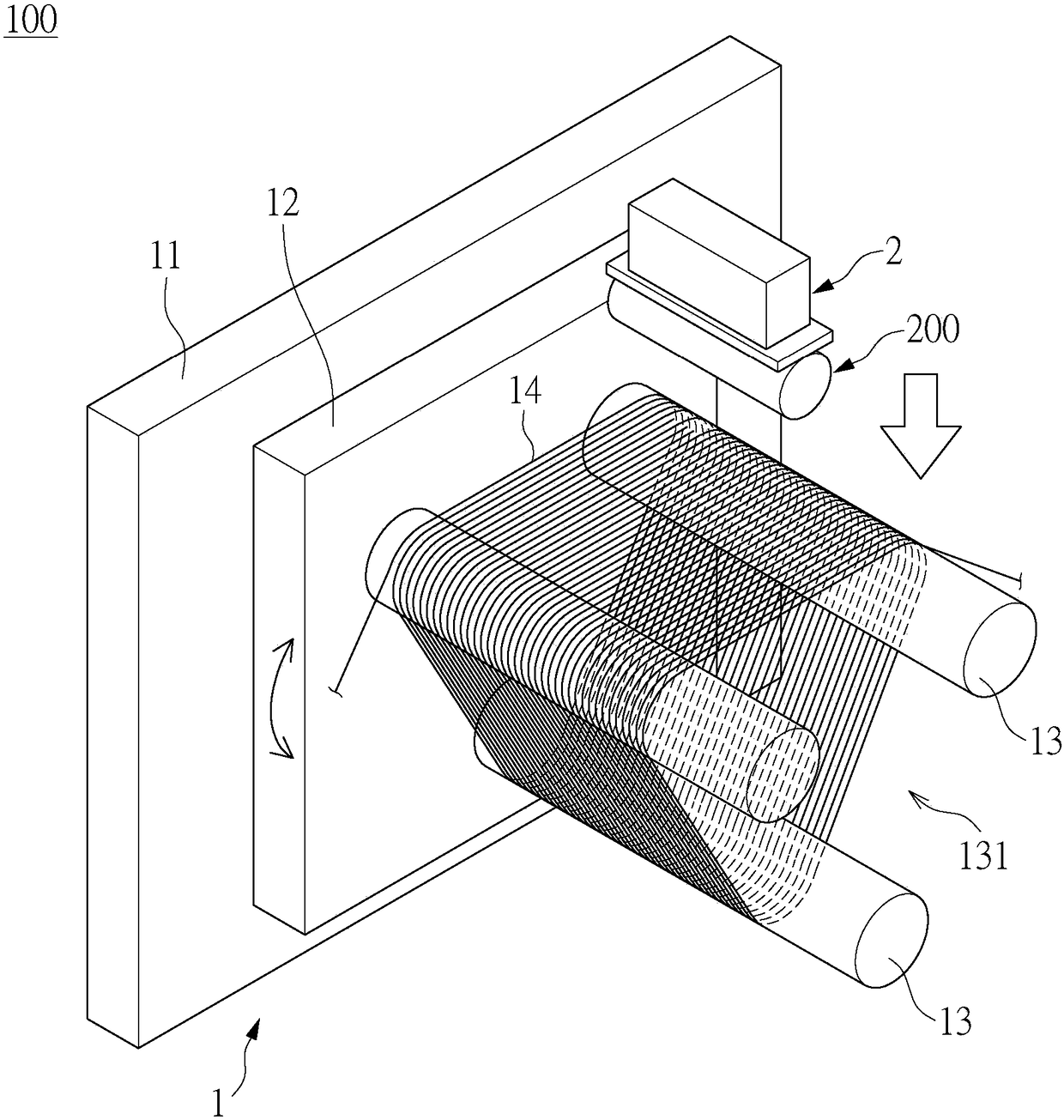

[0030] see Figure 3 to Figure 12 , is an embodiment of the present invention. It should be explained first that this embodiment corresponds to the relevant quantities and shapes mentioned in the drawings, and is only used to specifically illustrate the implementation of the present invention, so as to facilitate the understanding of the content of the present invention. It is not intended to limit the protection scope of the present invention.

[0031] Among them, this embodiment discloses a silicon carbide ingot slicing device 100 and a method for slicing a silicon carbide ingot, and to facilitate a clear understanding of this embodiment, the following will first describe the silicon carbide ingot slicing device 100, and then Next, the slicing method of the silicon carbide ingot is introduced.

[0032] Such as Figure 3 to Figure 5 , the silicon carbide ingot slicing device 100 is used to slice a cylindrical silicon carbide ingot 200 (such as a single crystal silicon carbi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com