Production process for preparing fiber-grade nylon 6 chips with extracted aqueous concentrated solution and apparatus thereof

A production process and a technology for a concentrated solution are applied in the production process and the field of devices for preparing spinning-grade nylon 6 chips by extracting a water concentrated solution, and can solve the problems of low solubility, high operation difficulty, low reactivity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

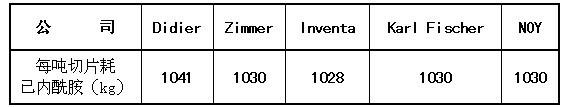

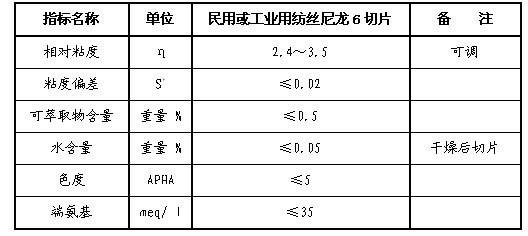

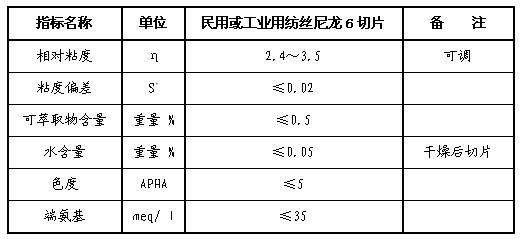

[0031] See attached figure 1 to attach Figure 9, the production process for preparing spinning-grade nylon 6 slices from the extract water concentrate disclosed in the present invention comprises the following steps: 1. Pressure filtration: the extract water concentrate in the extract water concentrate storage tank 1 is passed through a high-temperature filter press 2 Press filtration, remove impurity, send to concentrated solution storage tank 3 after press filtration, present embodiment is preferred, also set crystallization tank 4 between extraction water concentrated solution storage tank 1 and high-temperature filter press 2, to remove a small amount of high Impurities at melting point; two, configuration: first add the extraction water concentrate in the melting kettle 5, then add the pulverized solid caprolactam and the molecular weight stabilizer to the melting kettle 5, the molecular weight stabilizer is preferably benzoic acid, by carrying out the melting process on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com